Fully sulfurized hydrofining catalyst and preparation method thereof, and distillate oil hydrofining method

A hydrorefining and complete sulfurization technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem that the sulfurization degree and dispersion degree of active metal Ni are uncontrollable and disadvantageous, and the catalyst preparation cost is high. problems, to achieve good application prospects, reduce workload, and shorten the start-up time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

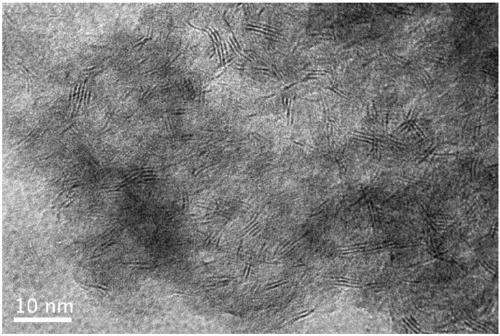

Image

Examples

Embodiment 1

[0047] Take 100g of pseudo-boehmite, add 4g of scallop powder, mix evenly, add dropwise an aqueous solution containing 4g of nitric acid and 4g of citric acid and knead, extrude into a clover shape of 1.5mm, dry at 120°C for 2h, and then roast at 550°C for 4h. Make a carrier.

[0048] Get 13.0g ammonium thiomolybdate [(NH 4 ) 2 MoS 4 ], 1.41g CS (NH 2 ) 2 , 3.38g nickel nitrate, 2.13g L-proline, 50mL deionized water, stir until completely dissolved.

[0049] 20.38g of the carrier and the above solution were respectively added into a 100mL hydrothermal reaction kettle, and crystallized at 200°C for 24h.

[0050] The product was washed and dried to obtain Catalyst A.

Embodiment 2

[0052] Take 100g of pseudo-boehmite, add 4g of scallop powder, mix evenly, add dropwise an aqueous solution containing 4g of nitric acid and 4g of citric acid and knead, extrude into a clover shape of 1.5mm, dry at 120°C for 2h, and then roast at 550°C for 4h. Make a carrier.

[0053] Get 13.0g ammonium thiomolybdate [(NH 4 ) 2 MoS 4 ], 1.41g CS (NH 2 ) 2 , 3.38g nickel nitrate, 2.13g L-proline, 50mL deionized water, stir until completely dissolved.

[0054] 24.20 g of the carrier and the above solution were respectively added into a 100 mL hydrothermal reaction kettle, and crystallized at 230° C. for 16 h.

[0055] The product was washed and dried to obtain Catalyst B.

Embodiment 3

[0057] Take 100g of pseudo-boehmite, add 4g of scallop powder, mix evenly, add dropwise an aqueous solution containing 4g of nitric acid and 4g of citric acid and knead, extrude into a clover shape of 1.5mm, dry at 120°C for 2h, and then roast at 550°C for 4h. Make a carrier.

[0058] Get 13.0g ammonium thiomolybdate [(NH 4 ) 2 MoS 4 ], 1.41g CS (NH 2 ) 2 , 3.38g nickel nitrate, 2.13g L-proline, 50mL deionized water, stir until completely dissolved.

[0059] 29.12 g of the carrier and the above solution were respectively added into a 100 mL hydrothermal reaction kettle, and crystallized at 210° C. for 20 h.

[0060] The product was washed and dried to obtain catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com