Preparation method of antibacterial air conditioner filter element material

A filter element and air conditioner technology, applied in the directions of botanical equipment and methods, separation methods, chemical instruments and methods, etc., can solve the problem of high cost, achieve stable properties, excellent adsorption performance, and improve the effect of antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

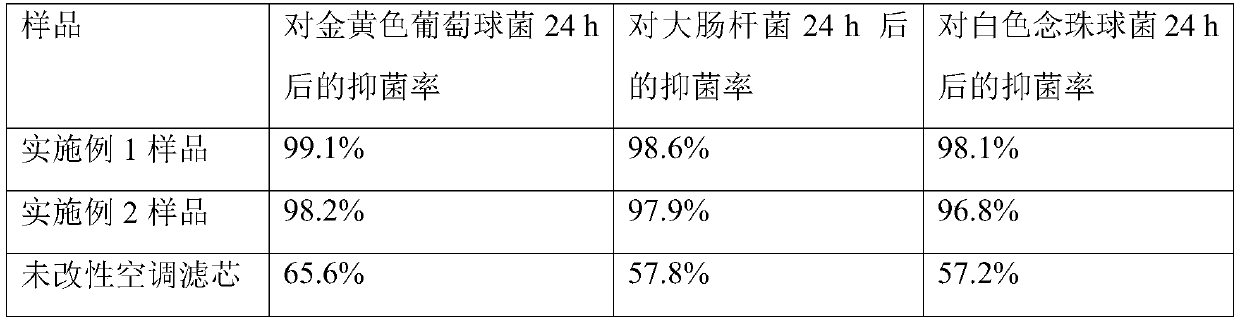

Examples

Embodiment 1

[0019] A preparation method of an antibacterial air-conditioning filter element material adopts the following steps:

[0020] 1) Zinc oxide nanoparticles are configured into a zinc oxide solution with a concentration of 0.001mol / L, then a silver nitrate solution with a concentration of 0.01mol / L is added, the solvent is water, the molar ratio of Zn:Ag is 1:1, and the Light irradiation for 2 hours, and assisted ultrasonic dispersion for 50 minutes, to obtain uniformly dispersed nano-zinc oxide-silver sol;

[0021] 2) Take the mesh fiber made of stainless steel as the carrier, and soak the metal mesh fiber carrier in the nano-zinc oxide-silver particle sol at a molar ratio of 1:9 for 0.5h;

[0022] 3) The metal mesh fiber carrier loaded with zinc oxide-silver nano sol is taken out and dried at 120°C to obtain a metal mesh antibacterial self-cleaning air conditioning filter element material loaded with nano zinc oxide-silver particles.

[0023] 4) Place the millimeter-scale biop...

Embodiment 2

[0026] A preparation method of an antibacterial air-conditioning filter element material adopts the following steps:

[0027] 1) Zinc oxide nanoparticles are configured into a zinc oxide solution with a concentration of 0.01mol / L, then a silver nitrate solution with a concentration of 0.05mol / L is added, the solvent is a 1:1 mixture of ethanol and water, and the molar ratio of Zn:Ag is 3:1, irradiated by a high-pressure mercury lamp for 3 hours, and assisted by ultrasonic dispersion for 30mim, to obtain a uniformly dispersed nano-zinc oxide-silver sol;

[0028] 2) Take the mesh fiber made of aluminum alloy as the carrier, soak the metal mesh fiber carrier in the nano-zinc oxide-silver particle sol, seal it in an autoclave and heat it to 80°C, and react for 3 hours;

[0029] 3) The metal mesh fiber carrier loaded with zinc oxide-silver nano sol is taken out and dried at 80°C to obtain a metal mesh antibacterial self-cleaning air conditioning filter element material loaded with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com