Carbon nanotube surface molecularly-imprinted solid phase extraction column for carbofuran

A technology of surface molecular imprinting and solid phase extraction column, which is applied in separation methods, solid adsorbent liquid separation, preparation of test samples, etc., can solve the problem of low density of effective imprinting sites, small binding capacity of target molecules, binding kinetics, etc. Slow and other problems, to achieve the effect of high column capacity, good selectivity, and simple analysis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

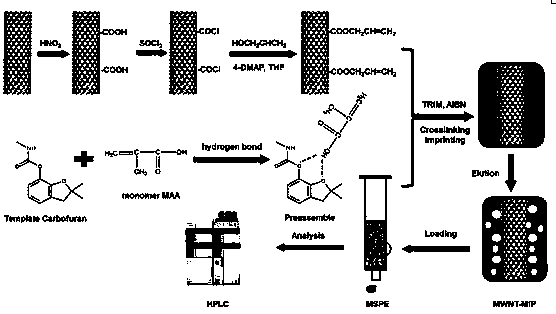

[0027] Example 1 Preparation of Molecularly Imprinted Polymer on the Surface of Carbofuran Carbon Nanotubes (SPE Column Packing)

[0028] Add 0.5g multi-walled carbon nanotubes to 100ml concentrated HNO 3 The solution was ultrasonically treated for 1 h, and then refluxed at 80° C. for 24 h under magnetic stirring. Afterwards, filter the dispersion with a 0.22 μm filter membrane, wash the obtained particles repeatedly with distilled water to neutrality, and dry them under vacuum at 65°C overnight for later use; In the mixed solution of chloroform, reflux at 60°C for 24h under magnetic stirring. After cooling, the mixture was dispersed through a 0.22 μm filter membrane with anhydrous tetrahydrofuran, and washed with distilled water several times until neutral, dried in vacuum at 65°C overnight, and set aside; Mix 0.15 g of the above-prepared carbon nanotubes with 0.87 g of allyl alcohol, 0.18 g of 4-DMAP and 4.5 g of triethylamine, add 20 ml of anhydrous THF, reflux at 50 ° C f...

Embodiment 2

[0029] Example 2 Preparation of Carbofuran Carbon Nanotube Surface Molecularly Imprinted Solid Phase Extraction Column

[0030] 1. Empty column material and specification

[0031] The size of the empty column of the existing solid phase extraction column varies from 1cm to 5cm. The empty column is made of polypropylene, and there are polyethylene sieve plates with 20 μm pore size on the upper and lower sides of the small column. The above-mentioned empty columns can all be used in the present invention, but the 3cm specification is adopted in the following examples.

[0032] 2. Packing of solid phase extraction column

[0033] The filler of the solid phase extraction column is molecularly imprinted polymer on the surface of carbofuran carbon nanotubes.

[0034] 3. Filling volume and filling height

[0035] Fill a 3cm solid-phase extraction column with the molecularly imprinted polymer on the surface of carbofuran carbon nanotubes prepared above, as shown in the attached fi...

Embodiment 3

[0036] Example 3 Separation and purification of carbofuran in biological samples by solid phase extraction

[0037] 4LD 50 (44 mg / kg) for intragastric administration. After the rat died, 1 g of its liver was taken, cut into pieces, added with 2 μg of carbaryl and 2 mL of water, and homogenized at 15,000 rpm for 3 min. The obtained carbofuran carbon nanotube surface molecularly imprinted solid-phase extraction column was completely infiltrated with 4ml of methanol and kept for 5min, and then let off the liquid at a rate of 1 drop / second. After the treatment, the small column was in an activated state; The sample flows through the extraction column at a speed of 2 ml / min, and the solvent component is removed by suction filtration, and then the solid-phase extraction column is eluted with methanol / acetic acid (90:10), and the qualitative and quantitative analysis is performed by high-performance liquid chromatography to obtain the liver The carbofuran content is 0.1-10 μg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com