Alginate/nano-clay composite microcarrier and preparing method and device

A technology of nano-clay and alginate, which is applied in prosthetics, medical science, etc., can solve the problems of incapable of endowing microcarriers with slow-release drug mechanical properties and high sterilization requirements, and achieve strong mechanical properties, improved mechanical properties, and better The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

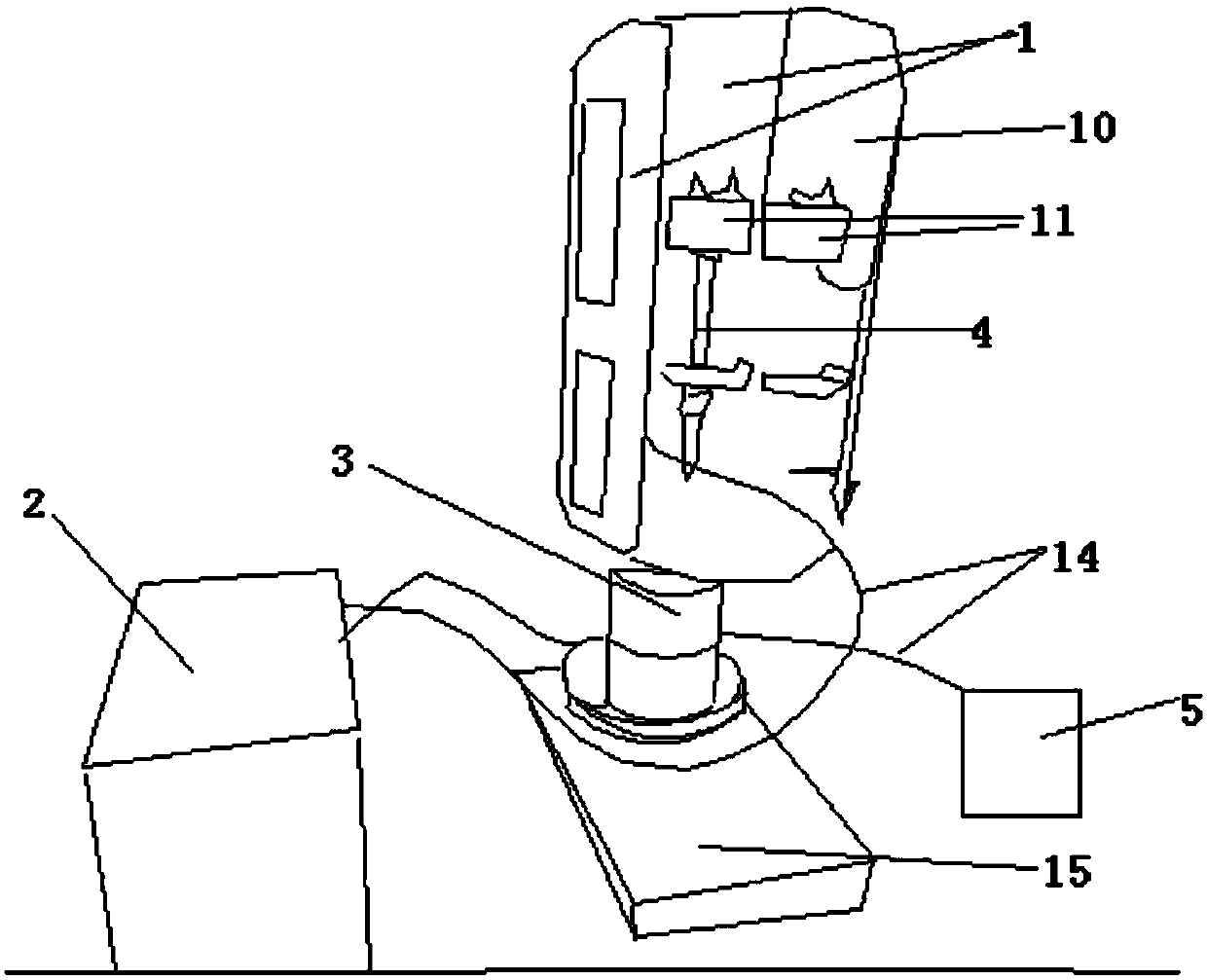

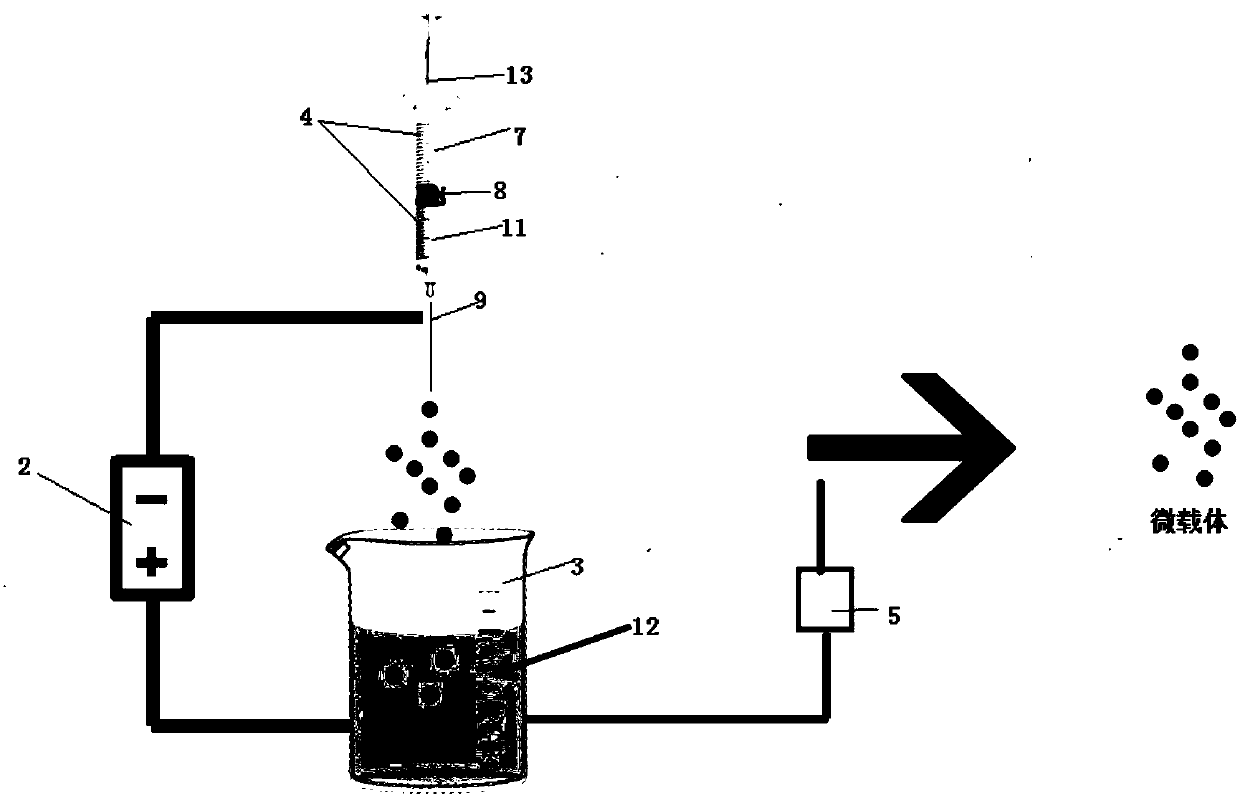

Method used

Image

Examples

Embodiment 1

[0054] Alginate / nano-clay composite microcarriers include alginate solution and nano-clay sol, the volume ratio of alginate solution and nano-clay sol is 1:1, alginate mainly exists in the form of calcium alginate, in which Ca 2+ The mass fraction is 10%. The carrier is spherical, with a particle size of 100 μm to 600 μm. The carrier is formed by flowing in a high-voltage electrostatic field of 5kV to 20kV.

[0055] The mass percentage concentration of sodium alginate solution is 1%; the mass percentage concentration of nanoclay sol is 0.1%; Ca 2+ The solution is CaCl 2 solution, the molar concentration of the solution is 0.05mol / L.

[0056] Alginate is sodium alginate or potassium alginate, soluble in water at 1% mass fraction at 25°C, its viscosity range is 4-12cP, and its purity should be higher than 99%; nanoclay material is a natural One or several mixtures of various layered silicate materials extracted or artificially synthesized, the purity of each component should...

Embodiment 2

[0065] Alginate / nano-clay composite microcarriers include alginate solution and nano-clay sol, the volume ratio of alginate solution and nano-clay sol is 1:1, alginate mainly exists in the form of calcium alginate, in which Ca 2+ The mass fraction is 13%. The carrier is spherical, with a particle size of 200 μm to 400 μm. The carrier is formed by flowing in a high-voltage electrostatic field of 20kV.

[0066] Carriers also include cells, which are adherent cells.

[0067] The mass percentage concentration of sodium alginate solution is 3%; the mass percentage concentration of nanoclay sol is 3%; Ca 2+ The solution is CaCl 2 solution, the molar concentration of the solution is 0.3mol / L.

[0068] Alginate is sodium alginate or potassium alginate, soluble in water at 1% mass fraction at 25°C, its viscosity range is 4-12cP, and the purity is higher than 99%; the nano-clay material is nano-montmorillonite (MMT), There are three kinds of nano-saponite or nano-lithium magnesium ...

Embodiment 3

[0077] Alginate / nano-clay composite microcarriers include alginate solution and nano-clay sol, the volume ratio of alginate solution and nano-clay sol is 1:1, alginate mainly exists in the form of calcium alginate, in which Ca 2+ The mass fraction is 12%. The carrier is spherical, with a particle size of 200 μm to 400 μm. The carrier is formed by flowing in a high-voltage electrostatic field of 12kV.

[0078] Carriers also include drugs and cells to be sustained release; drugs to be sustained release are biologically active factors or drug molecules, including growth factors such as various polypeptides and proteins, or small molecule drugs or combinations thereof, preferably factors with a molecular weight of less than 80kD to achieve better Sustained release effect; the cells are stem cells, such as bone marrow mesenchymal stem cells or dental pulp stem cells, through the method of transplanting stem cells to achieve the purpose of tissue regeneration.

[0079] The mass pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com