Lithium ion battery cathode material, preparation method therefor, and lithium ion battery

A technology for lithium ion batteries and cathode materials, which is applied in electrode manufacturing, battery electrodes, lithium batteries, etc., can solve the problems of cycle stability, poor rate performance and thermal stability, and side reactions of lithium cobalt oxide cathode materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

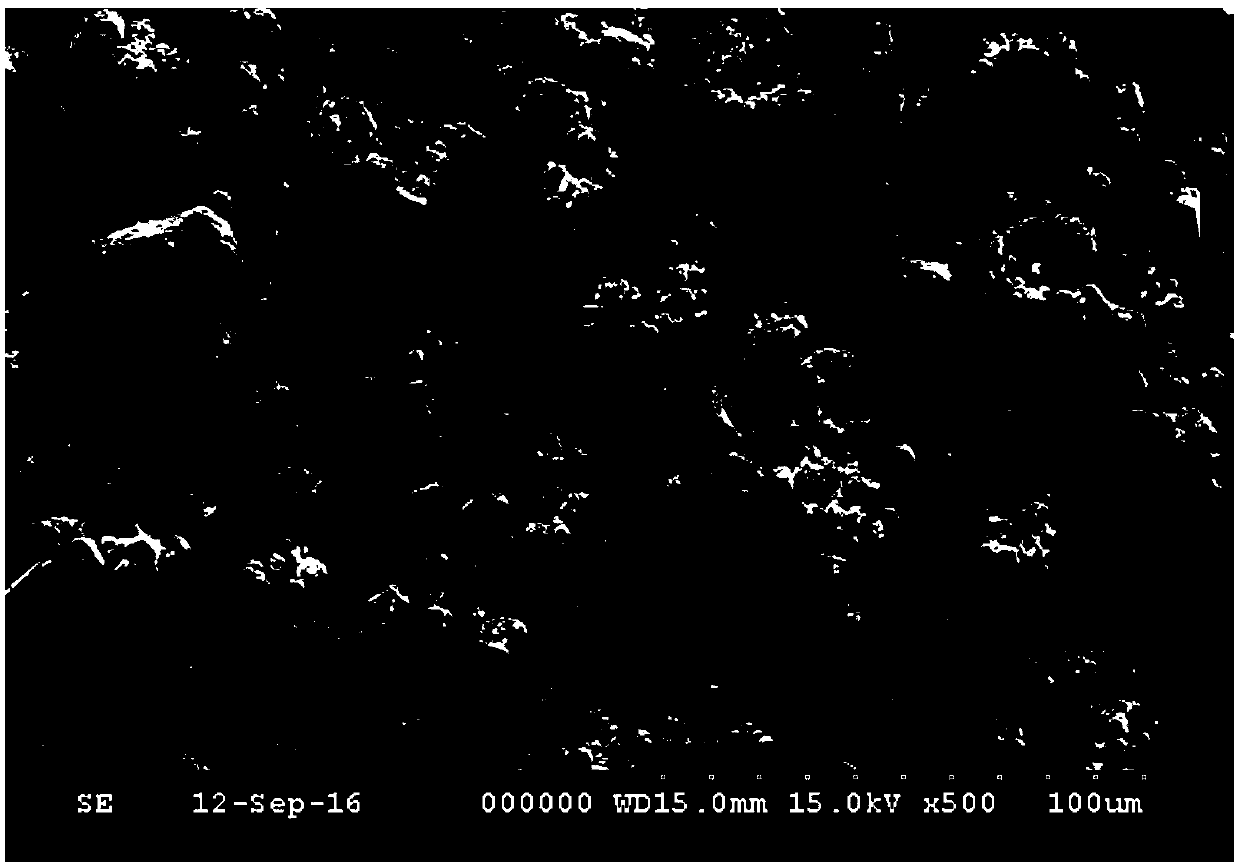

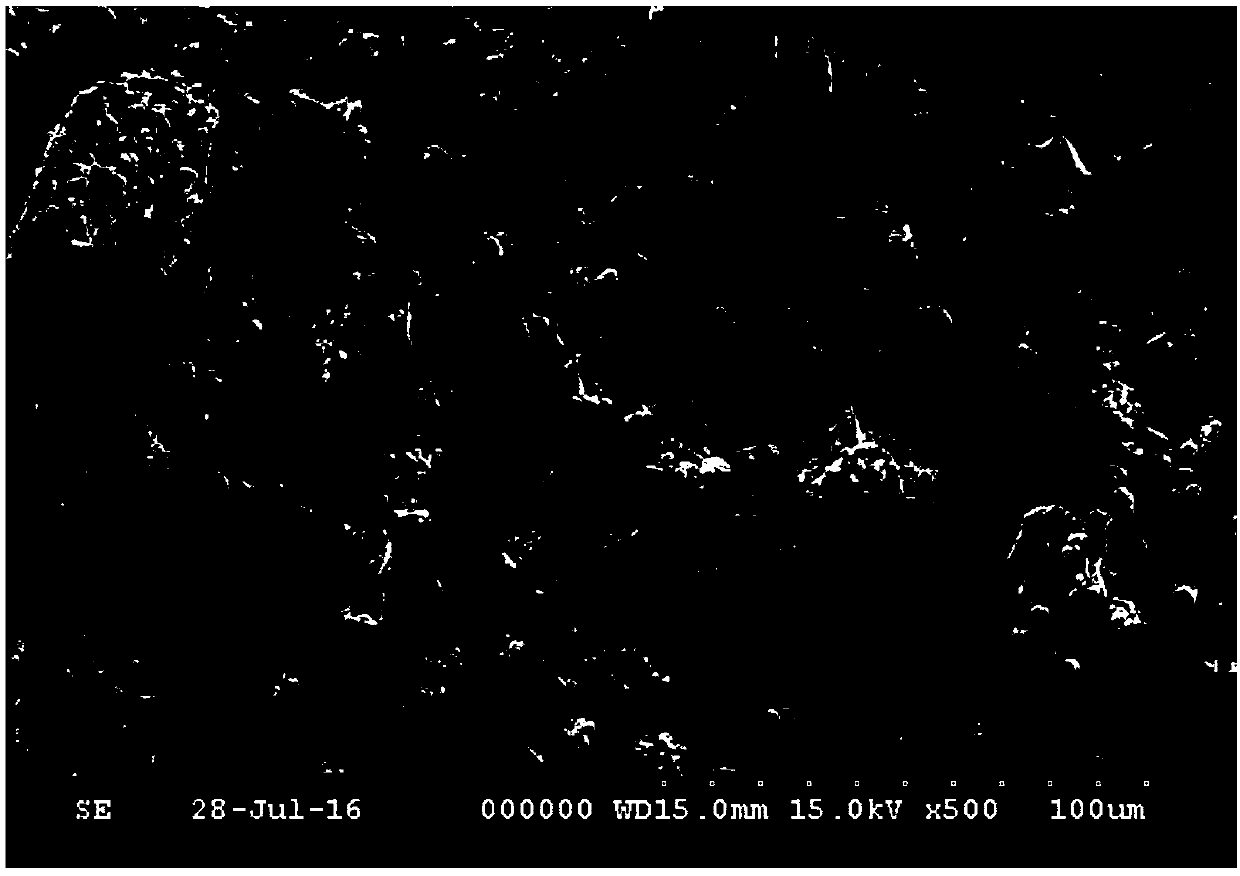

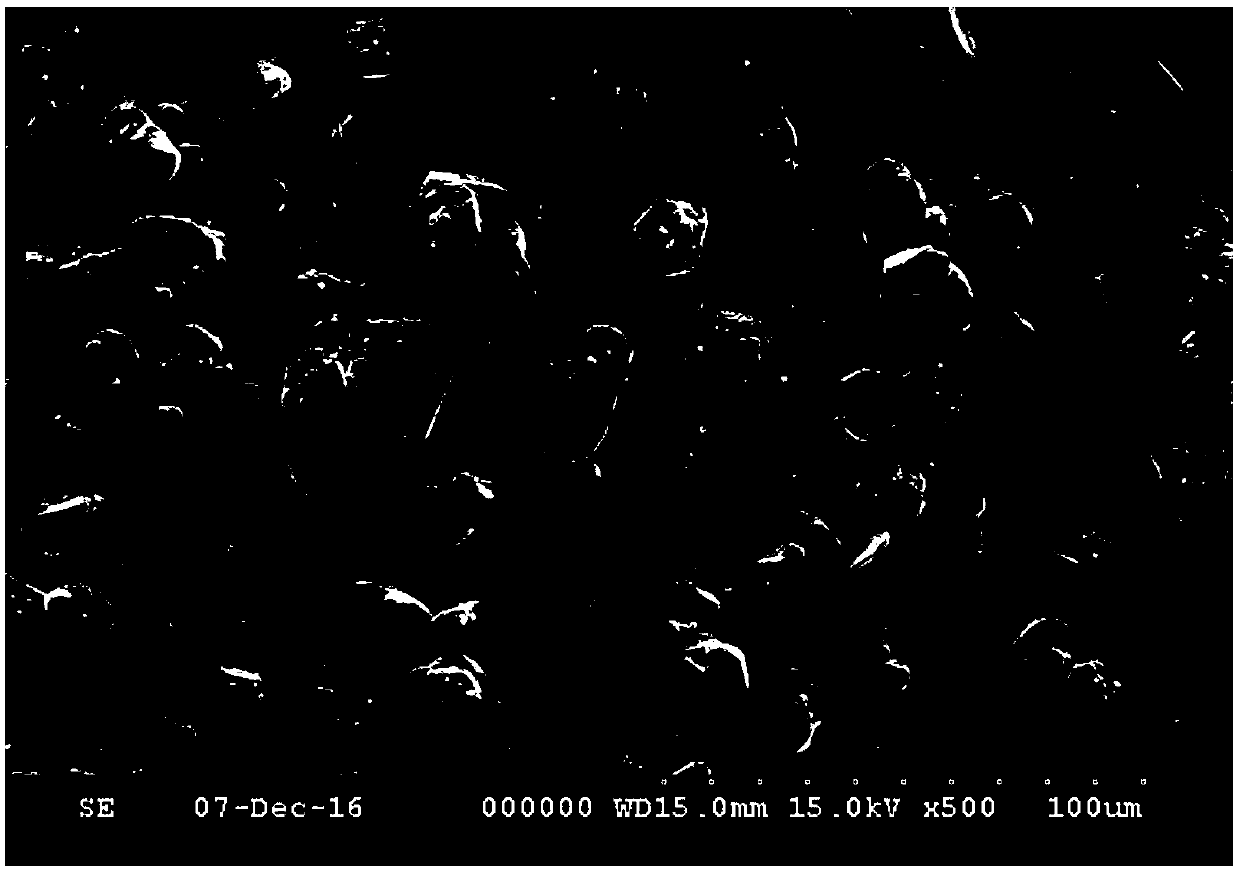

Image

Examples

preparation example Construction

[0051] Another aspect of the present invention provides a kind of preparation method according to above-mentioned positive electrode material of lithium ion battery, and its steps are as follows:

[0052] S1. Primary mixing: Mix cobalt salts and lithium compounds doped or undoped with M' elements, or add nanoscale additives containing M" elements to them and mix evenly, and control Li / Co at 1.00-1.06 range, control the cobalt salt particle size D50 between 13-16um, and mix uniformly to obtain a primary mixture. The M' element contains one or more of Al, Mg, Ti, Mn, and Ni, at least one of which is Al. Said M" is one or more elements in Al, Mg, Ti, Zr, Mn, Ni, at least one is Al;

[0053] S2. Primary sintering: sintering the primary mixture, the sintering includes raising the temperature to 700-900°C, heat-preserving and sintering for H1 hour, then continuing to heat up to 900-1100°C, heat-preserving and sintering for H2 hours to obtain the primary sintered material, the The s...

Embodiment 1

[0083] Preparation of large particle semi-finished product A of lithium cobaltate: Li / Co=1.05, Mg addition amount 1200ppm, weigh lithium carbonate, tricobalt tetroxide, Mg 2 CO 3 , wherein the Al element is doped in the tricobalt tetroxide, and the doping amount is about 2000ppm. The particle size D50 of tricobalt tetroxide is between 13-16um. After mixing these three materials in the ball mill for 5 hours, put the mixture into a sagger, send it into the pusher kiln, raise the temperature to 870°C at 3°C / min, keep it warm for 3.5 hours, then raise the temperature to 1050°C, and keep it warm for 6 hours. The sintered material is crushed and sieved to obtain a semi-finished product of large particles of lithium cobaltate, and the particle size of the semi-finished lithium cobaltate is about 19um.

[0084] Preparation of lithium cobaltate small particle semi-finished product C: press Li / Co=1.03, Ti addition 500ppm takes lithium carbonate, tricobalt tetroxide, TiO 2 , wherein c...

Embodiment 2

[0089] Preparation of lithium cobaltate large particle semi-finished product B: Li / Co=1.05, Mg addition 2200ppm, Zr addition 500, weigh lithium carbonate, tricobalt tetroxide, Mg 2 CO 3 , ZrO 2 , in which cobalt tetroxide is not doped with other elements except Co and O. The particle size D50 of tricobalt tetroxide is between 13-16um. After these four kinds of materials are mixed in the ball mill for 5 hours, the mixed materials are put into the sagger, sent into the pusher kiln, the temperature is raised to 870°C at 3°C / min, kept for 3.5 hours, then raised to 1050°C, kept for 6 hours, The sintered material is crushed and sieved to obtain a semi-finished product of large particles of lithium cobaltate, and the particle size of the semi-finished lithium cobaltate is about 19um.

[0090] The semi-finished product C of lithium cobaltate small particles was prepared as described in Example 1.

[0091] Mix the semi-finished products of B and C lithium cobalt oxide particles at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com