Silicon/expanded graphite/amorphous carbon composite material and preparation method thereof

A technology of expanded graphite and amorphous carbon, which is applied to electrical components, battery electrodes, circuits, etc., can solve problems such as low electrical conductivity, decreased electrode cycle performance, and loss of current collector electrical contact, and achieve high electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

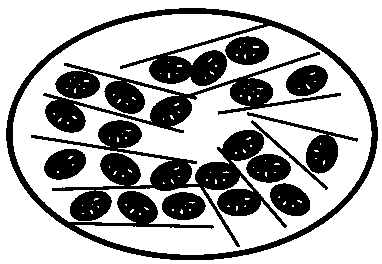

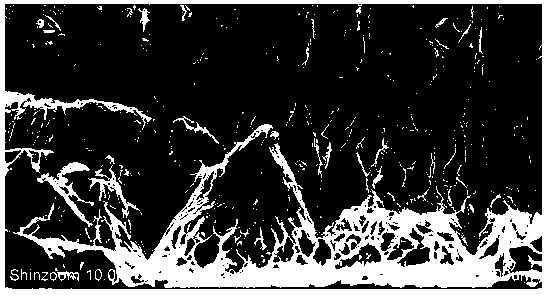

Image

Examples

Embodiment 1

[0026] Step 1. At room temperature, mix ethyl orthosilicate, absolute ethanol and deionized water in a mass ratio of 1:6:4 and stir evenly, slowly add 0.01mol / L oxalic acid solution dropwise to make it hydrolyze, then add dropwise 0.1mol / L of ammonia water was stirred evenly, and left to stand to form an alcohol gel. Put the alcogel seal in a constant temperature water bath at 50°C for aging to obtain a high-strength three-dimensional network structure. Finally, the gel is subjected to supercritical drying to obtain SiO2 airgel block solid.

[0027] Step 2. Mix SiO2 airgel block solid and magnesium powder into two special steel boats at a molar ratio of 2.5:1, then put the steel boats into a container protected by argon and seal them, and then place the sealed Put the container into a tube furnace, raise the temperature to 600°C in an argon atmosphere, keep it warm for 1 h, then cool it down to room temperature, then put it in HCl solution, let it stand at room temperature f...

Embodiment 2

[0031] Step 1. At room temperature, mix and stir ethyl orthosilicate, absolute ethanol and deionized water according to the mass ratio of 1:6:4, slowly add a certain amount of 0.01mol / L oxalic acid solution to hydrolyze it, and then add dropwise 0.1mol / L ammonia water was stirred evenly, and left to stand to form an alcohol gel. It is sealed and aged in a constant temperature water bath at 50°C to obtain a high-strength three-dimensional network structure. Finally, the gel is subjected to supercritical drying to obtain SiO 2 Airgel block solid.

[0032] Step 2, the SiO 2 The airgel block solid and magnesium powder are mixed into two special steel boats at a molar ratio of 5:1, and then the steel boats are put into a container protected by argon and sealed, and then the sealed container is put into a tube type In the furnace, raise the temperature to 900°C in an argon atmosphere, keep it warm for 5 hours, then cool it to room temperature, then put it in HCl solution, let it ...

Embodiment 3

[0036] Step 1. At room temperature, mix and stir ethyl orthosilicate, absolute ethanol and deionized water according to the mass ratio of 1:6:4, slowly add a certain amount of 0.01mol / L oxalic acid solution to hydrolyze it, and then add dropwise 0.1mol / L ammonia water was stirred evenly, and left to stand to form an alcohol gel. It is sealed and aged in a constant temperature water bath at 50°C to obtain a high-strength three-dimensional network structure. Finally, the gel is subjected to supercritical drying to obtain SiO 2 Airgel block solid.

[0037] Step 2, the SiO 2 Airgel block solid and magnesium powder are mixed into two special steel boats at a molar ratio of 3:1, and then the steel boats are put into a container protected by argon and sealed, and then the sealed container is put into a tube In the furnace, raise the temperature to 700°C under an argon atmosphere, keep it warm for 2 hours, then cool it down to room temperature, then place it in HCl solution for 5 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com