Preparation method of micro-cavity coupling system and microwave photon filter

A coupling system and microcavity technology, applied in the coupling of optical waveguides, light guides, optics, etc., can solve the problems that the suppression ratio cannot reach a high level stably, the Q value of the microcavity is difficult to further improve, and the manufacturing process is complicated. Achieve the effects of monitoring and adjusting processing technology, strong anti-interference ability and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

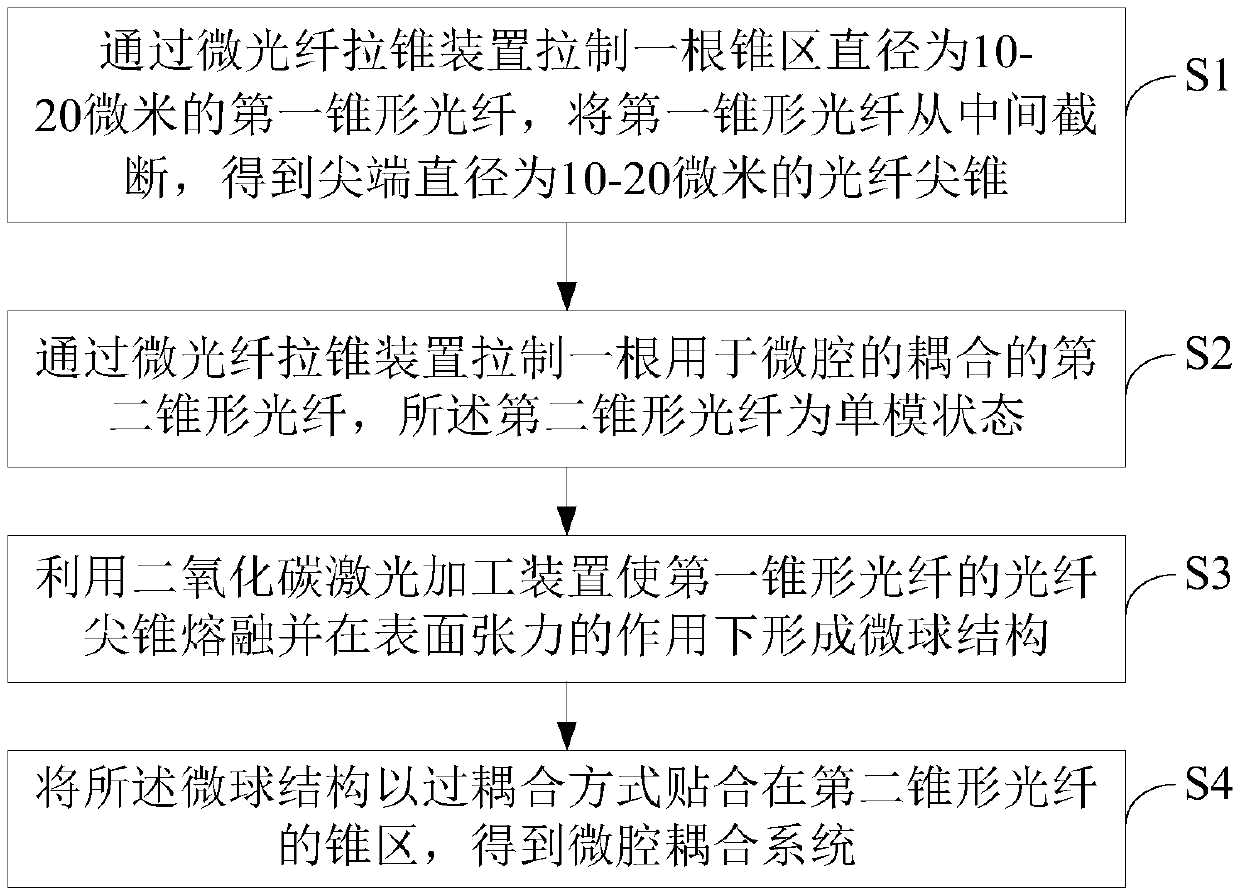

[0030] see figure 1 , one A preparation method of a microcavity coupling system, comprising:

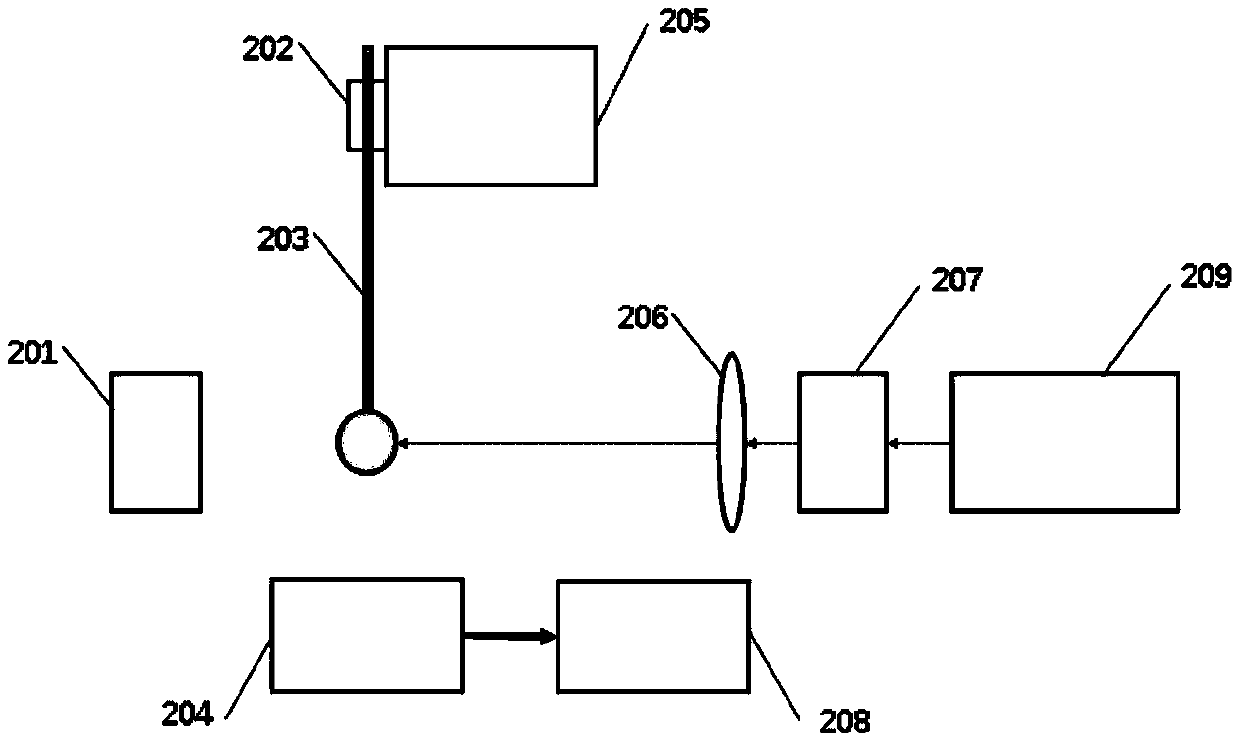

[0031] S1, drawing a first tapered optical fiber with a diameter of 10-20 microns in the tapered region through a micro-fiber tapering device, cutting the first tapered optical fiber from the middle to obtain a fiber tip 203 with a tip diameter of 10-20 microns ; see figure 2, the micro-fiber taper device includes a DFB laser 101, an electric displacement platform 107, two identical electric displacement sliders 102, two identical first optical fiber clamps 103, a data acquisition card 110, a first computer 109, an electric displacement A platform controller 108 and a hydrogen-oxygen flame high-temperature spray gun 106 for heating the single-mode optical fiber; wherein the two electric displacement sliders 102 are installed on the guide rail of the electric displacement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tip diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com