Environmentally-friendly energy-saving type recycling treatment system for oil sludge circulating fluidized bed

A circulating fluidized bed and treatment system technology, applied in the field of oil sludge circulating fluidized bed environmental protection and energy-saving resource treatment system, can solve the problems of lack of deacidification device and ash removal device, and the difficulty of flue gas to meet emission standards, etc. The effect of less space, compact equipment layout and simple processing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

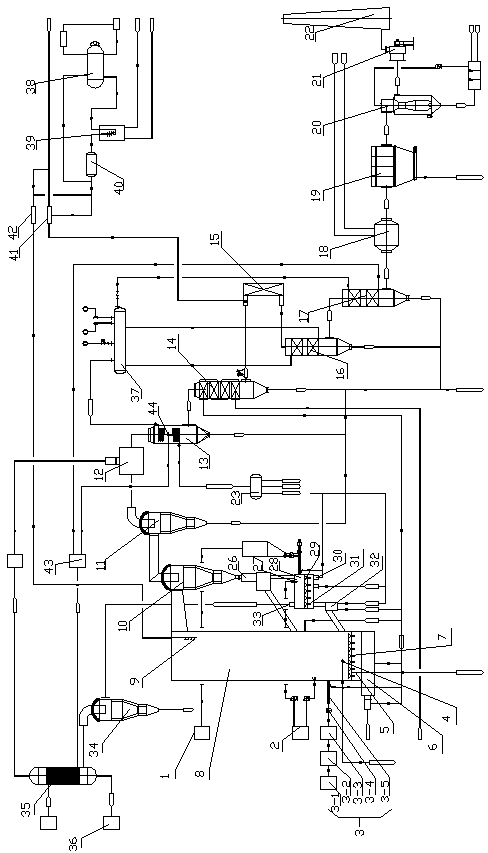

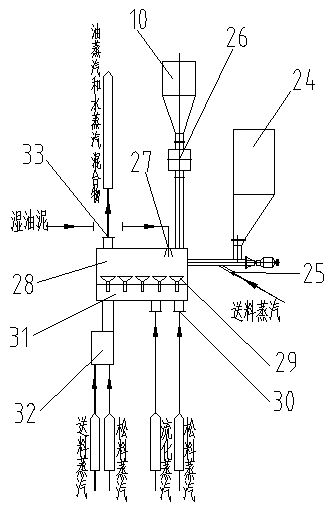

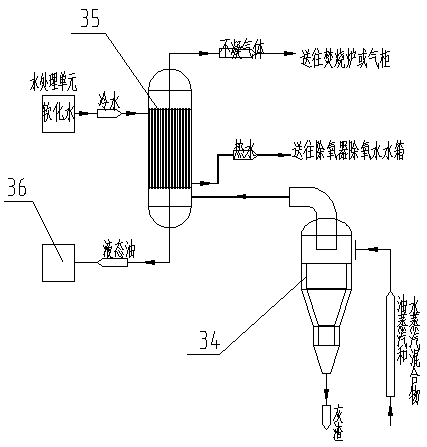

[0021] Example 1: See Figure 1-Figure 3 , an oil sludge circulating fluidized bed environmental protection and energy-saving resource treatment system, the main equipment includes: oil sludge pretreatment and feeding system, circulating fluidized bed oil sludge incineration system, oil sludge fluidization gasification system, waste heat utilization of flue gas on the incineration side Six systems, including environmental protection system for flue gas on the incineration side, and reaction gas purification system on the gasification side;

[0022] The sludge pretreatment and feeding system is divided into a dry sludge gasification feeding system 1 , a wet sludge feeding system 2 , and a dry sludge burning feeding system 3 . The dry sludge in the dry sludge gasification feeding system 1 and the dry sludge burning feeding system 3 is crushed by the vibrating crusher 3-1, and then sent to the dry sludge storage tank 3-3 through the bucket elevator conveyor 3-2, and passed throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com