PE-PS alloy with high conductivity

A PE-PS, electrical conductivity technology, applied in the field of polymer materials, can solve the problems of poor compatibility and high catalyst cost, and achieve the effects of improved compatibility, excellent wear resistance and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

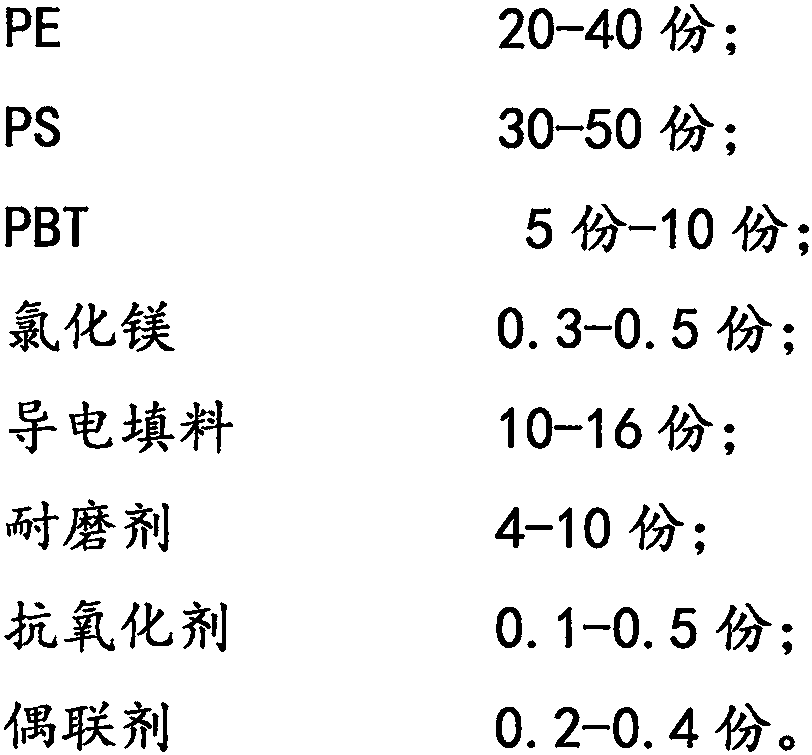

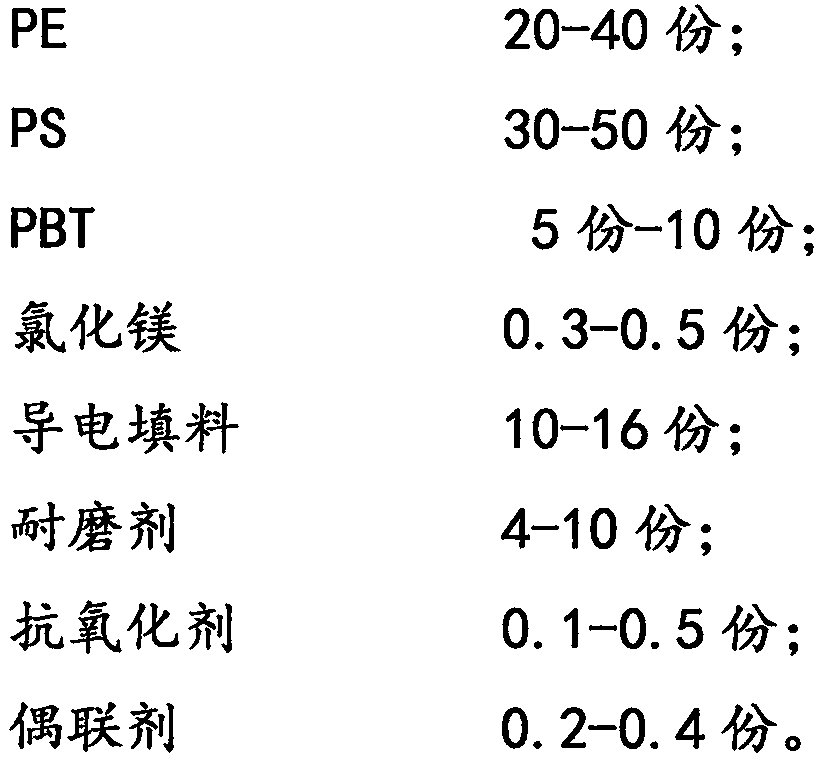

Method used

Image

Examples

Embodiment 1

[0023] Weigh 20 parts of PE, 30 parts of PS, 5 parts of PBT, 2 parts of boron carbide, 2 parts of tetrafluoroethylene, 10 parts of graphene, 0.3 parts of MgCl 2 , 0.05 parts of Irganox1010, 0.05 parts of Irganox168 and 0.2 parts of AC-201.

[0024] The above materials were stirred together by a high-speed mixer for 10 minutes to form a mixed material. Among them, the temperature of the high-speed mixer is 70° C., and the rotation speed is 120 r / min.

[0025] The mixed material is put into the hopper of the twin-screw extruder, and the obtained product is melted, extruded and granulated, water-cooled, diced and dried.

[0026] The twin-screw extruder consists of six zones, in which the temperature and screw speed of each zone are respectively: the temperature of the first zone is 150°C, the temperature of the second zone is 170°C, the temperature of the third zone is 170°C, the temperature of the fourth zone is 170°C, the temperature of the fifth zone is 170°C, and the tempera...

Embodiment 2

[0028] Weigh 40 parts of PE, 50 parts of PS, 10 parts of PBT, 5 parts of boron carbide, 5 parts of tetrafluoroethylene, 16 parts of graphene, 0.5 parts of MgCl 2 , 0.25 parts of Irganox1010, 0.25 parts of Irganox168 and 0.4 parts of AC-201.

[0029] The materials were stirred together by a high-speed mixer for 12 minutes to form a mixed material. Among them, the temperature of the high-speed mixer is 120° C., and the rotation speed is 240 r / min.

[0030] The mixed material is put into the hopper of the twin-screw extruder, and the obtained product is melted, extruded and granulated, water-cooled, diced and dried.

[0031] The twin-screw extruder consists of six zones, in which the temperature and screw speed of each zone are respectively: the temperature of the first zone is 180°C, the temperature of the second zone is 200°C, the temperature of the third zone is 200°C, the temperature of the fourth zone is 200°C, the temperature of the fifth zone is 200°C, and the temperature...

Embodiment 3

[0033] Weigh 30 parts of PE, 40 parts of PS, 8 parts of PBT, 3.5 parts of boron carbide, 3.5 parts of tetrafluoroethylene, 13 parts of graphene, 0.3 parts of MgCl 2 , 0.15 parts of Irganox1010, 0.15 parts of Irganox168 and 0.3 parts of AC-201.

[0034] The materials were stirred together by a high-speed mixer for 11 minutes to form a mixed material. Wherein the temperature of the high-speed mixer is 95° C., and the rotation speed is 180 r / min.

[0035] The mixed material is put into the hopper of the twin-screw extruder, and the obtained product is melted, extruded and granulated, water-cooled, diced and dried.

[0036] The twin-screw extruder consists of six zones, in which the temperature and screw speed of each zone are respectively: the temperature of the first zone is 165°C, the temperature of the second zone is 185°C, the temperature of the third zone is 185°C, the temperature of the fourth zone is 185°C, the temperature of the fifth zone is 185°C, and the temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com