Temperature-resistant and moisture-proof silica aerogel composite material and preparation method and application thereof

A composite material and silica technology, which is applied in the field of temperature-resistant and moisture-proof silica aerogel composite materials and their preparation, can solve the problems such as the inability to achieve performance stability and repeatability improvement, and meet the requirements of repeated use. Stable performance, breaking through the hydrophobic temperature limit, good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

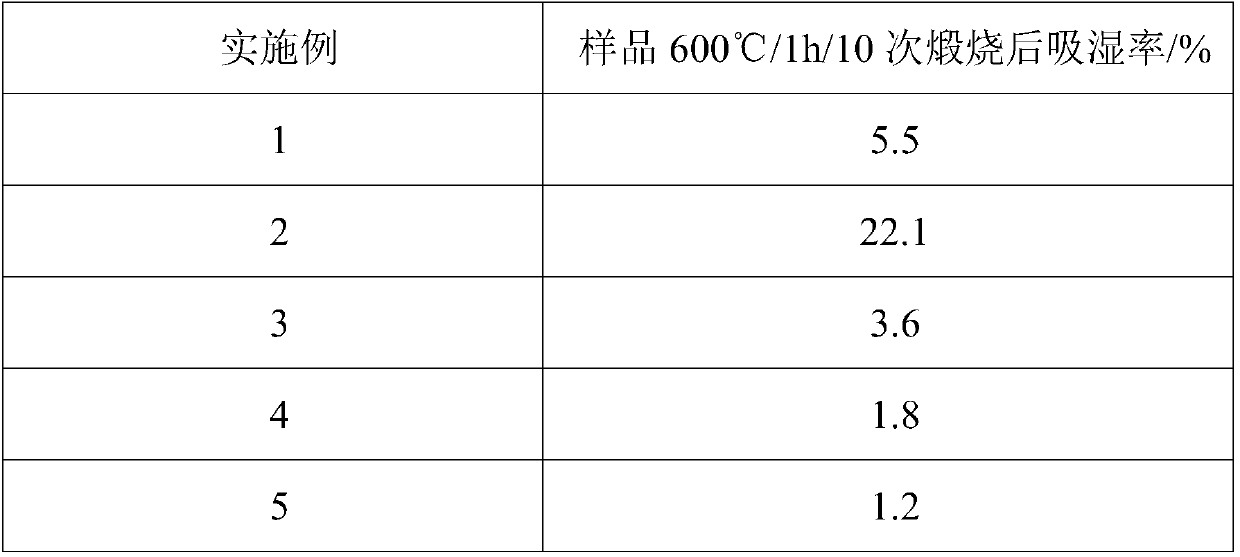

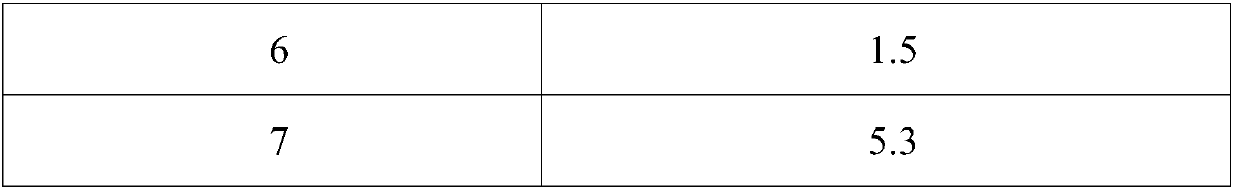

Embodiment 1

[0049] Dissolve tridecafluorooctyltrimethoxysilane, methyl orthosilicate, formic acid, and deionized water in a molar ratio of 10:50:4.8:240 in a 600 molar equivalent ethanol solution, and stir at room temperature for 12 hours. Set the density to 0.1g / cm 3 Put the prefabricated body of quartz fiber felt into the mold, and use the vacuum pressure molding method to compound the above-mentioned silica sol with the prefabricated body under the condition of alkali catalysis (controlling the pH value between 8 and 9), and then aging at room temperature 36h, 90°C high-temperature aging for 36h, acetone solvent replacement 3 times after aging, and supercritical carbon dioxide drying to obtain fiber-reinforced silica airgel composite materials. After testing, the density of the prepared material is 0.25g / cm 3 , The temperature resistance is 600°C, the thermal conductivity at room temperature is 0.021W / m.K (according to the standard GB / T 10295-2008), and the moisture absorption rate of...

Embodiment 2

[0051] Carried out in the same manner as in Example 1, the difference is that tridecafluorooctyltrimethoxysilane is not added in step (1), but methyl orthosilicate is used instead of tridecafluorooctyltrimethoxy Silane, so that tridecafluorooctyltrimethoxysilane, methyl orthosilicate, formic acid, and deionized water are dissolved in 600 molar equivalents of ethanol solution in a molar ratio of 0:60:4.8:240; in addition, no Surface Modification. It was found that the hydrophobic effect of the product was poor, and the sample did not have a moisture-proof effect (according to the standard GB / T 21655.1-2008). The inventor also observed the moisture absorption rate of the composite sample after 600°C / 3600s / 10 times of use, and the results are shown in Table 1 below.

Embodiment 3

[0053] Carried out in substantially the same manner as in Example 1, the difference is that the treated material is further placed in a closed container after being placed at room temperature, and a catalytic amount of formic acid solution and 5% by mass of pentafluorophenyltrimethylpentamethamine accounting for the total amount of the material are added. Oxysilane is subjected to hydrophobization treatment after vacuuming, the treatment temperature is 50° C., and the treatment time is 8 hours, and then dried by vacuuming to obtain a fiber-reinforced silica airgel composite material. After testing, the density of the obtained material is 0.24g / cm 3 , The temperature resistance is 600°C, the thermal conductivity at room temperature is 0.022W / m.K (according to the standard GB / T 10295-2008), and the moisture absorption rate of the spherical heat shield after repeated use at 600°C is 3.6% (according to the standard GB / T 21655.1- 2008), the reusability of the material is significan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal conductivity at room temperature | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com