Comprehensive processing utilizing method for chromium-containing waste acid

A comprehensive treatment, chromium waste technology, applied in filtration treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of cumbersome operation, high cost of filter cake reprocessing, and more sediments, etc., to improve economic value, The effect of reducing waste and reducing disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

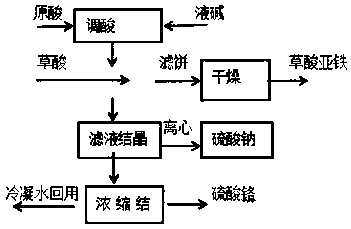

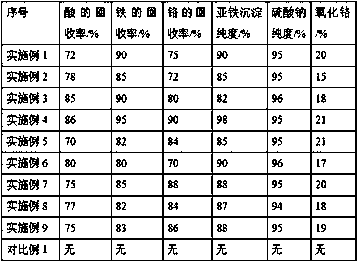

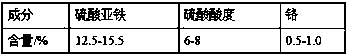

[0032] A comprehensive treatment and utilization method for chromium-containing waste acid, such as figure 1 shown, including the following steps:

[0033] S1. Adjust the pH value of the chromium-containing waste acid to 1.5, add acid to cause precipitation reaction with iron ions, add acid and then stir for 20 minutes, filter and separate to obtain ferrous precipitate and filtrate, maintain the pH value of the system at 1.5 during the acid addition process, the acid The addition amount is 1.1 times of iron ion in waste acid, and acid is the mixed acid of citric acid, oxalic acid, acetic acid and EDTA, and wherein the mass ratio of citric acid, oxalic acid, acetic acid and EDTA is 5:2:1:1;

[0034] S2. The above separated filtrate is cooled and precipitated to crystallize, filtered twice, and the filter cake is dried in the shade to obtain crystalline sodium sulfate Na 2 SO 4 .10H 2 O and secondary filtrate;

[0035] S3. The above-mentioned secondary filtrate is evaporated...

Embodiment 2

[0037] A method for comprehensive treatment and utilization of chromium-containing waste acid, comprising the following steps:

[0038] S1. Adjust the pH value of chromium-containing waste acid to 1, add acid to cause precipitation reaction with iron ions, add acid and then stir for 20 minutes, filter and separate to obtain ferrous precipitate and filtrate, maintain the system pH value at 1 during the acid addition process, acid The addition amount of the acid is 1.1 times of the iron ion in the waste acid, and the addition speed of the acid is controlled so that the pH value of the system after the addition is ≥0.5, and the acid is a mixed acid of citric acid, oxalic acid, acetic acid and EDTA, wherein citric acid, oxalic acid, acetic acid and EDTA The amount ratio of substances is 4.5:2:1:1;

[0039] S2. The above separated filtrate is cooled and precipitated to crystallize, filtered twice, and the filter cake is dried in the shade to obtain crystalline sodium sulfate Na 2 ...

Embodiment 3

[0042] A method for comprehensive treatment and utilization of chromium-containing waste acid, comprising the following steps:

[0043] S1. Adjust the pH value of the chromium-containing waste acid to 3, add acid to cause precipitation reaction with iron ions, add acid and then stir for 20 minutes, filter and separate to obtain ferrous precipitate and filtrate, maintain the pH value of the system at 3 during the acid addition process, acid The addition amount of the acid is 1.1 times of the iron ion in the waste acid, and the addition speed of the acid is controlled so that the pH value of the system after the addition is ≥0.5, and the acid is a mixed acid of citric acid, oxalic acid, acetic acid and EDTA, wherein citric acid, oxalic acid, acetic acid and EDTA The molar ratio of substances is 5:2.5:1:1;

[0044] S2. The above separated filtrate is cooled and precipitated to crystallize, filtered twice, and the filter cake is dried in the shade to obtain crystalline sodium sulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com