High-toughness titanium type flux-cored wire for weathering steel

A technology of titanium-type flux cored and flux-cored wire, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the adverse effects of impact toughness, titanium-type flux-cored wire cannot meet the requirements, titanium-type flux-cored Solve the impact toughness of welding wire and other issues, and achieve the effect of excellent low temperature impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A high-toughness titanium type flux-cored welding wire for weathering steel, comprising a flux core and a sheath; the flux core accounts for 12.5% of the total mass of the welding wire;

[0035] The drug core includes the following components in parts by weight: 480 parts of rutile, 30 parts of sodium fluoride, 12 parts of rare earth fluoride, 46 parts of potassium silicon titanate, 165 parts of silico-manganese alloy, 14 parts of medium carbon ferromanganese, metal Manganese 45 parts, magnesium powder 54 parts, nickel powder 80 parts, copper powder 20 parts, titanium iron 28 parts, boron iron 4 parts, iron powder 90 parts.

[0036] Experimental results:

[0037] The deposited metal of the flux-cored wire satisfies that Cr accounts for 0.03% of the total mass of the total deposited metal. The tensile strength of the deposited metal of the flux-cored wire is 590MPa, the yield strength is 500MPa, the elongation is 25.0%, KV 2 (-60°C) 91J.

[0038] Corrosion resistance index I:...

Embodiment 2

[0040] A high-toughness titanium type flux-cored welding wire for weathering steel, comprising a flux core and a sheath; the flux core accounts for 13.8% of the total mass of the welding wire;

[0041] The drug core includes the following components in parts by weight: 420 parts of rutile, 27 parts of sodium fluoride, 6 parts of rare earth fluoride, 40 parts of potassium silicon titanate, 150 parts of silico-manganese alloy, 12 parts of medium carbon ferromanganese, metal 38 parts of manganese, 45 parts of magnesium powder, 63 parts of nickel powder, 16 parts of copper powder, 24 parts of titanium iron, 3 parts of boron iron, and 185 parts of iron powder.

[0042] Experimental results:

[0043] The deposited metal of the flux cored wire satisfies that Cr accounts for 0.02% of the total mass of the total deposited metal. Flux cored wire deposit metal tensile strength 581MPa, yield strength 492MPa, elongation rate 27.5%, KV 2 (-60°C) 107J.

[0044] Corrosion resistance index I: 6.75.

Embodiment 3

[0046] A high-toughness titanium type flux-cored welding wire for weathering steel, comprising a flux core and a sheath; the flux core accounts for 15.0% of the total mass of the welding wire;

[0047] The drug core includes the following components in parts by weight: 370 parts of rutile, 24 parts of sodium fluoride, 4 parts of rare earth fluoride, 35 parts of potassium silicon titanate, 132 parts of silicon-manganese alloy, 10 parts of medium carbon ferromanganese, metal Manganese 30 parts, magnesium powder 40 parts, nickel powder 58 parts, copper powder 15 parts, titanium iron 20 parts, boron iron 2 parts, iron powder 250 parts.

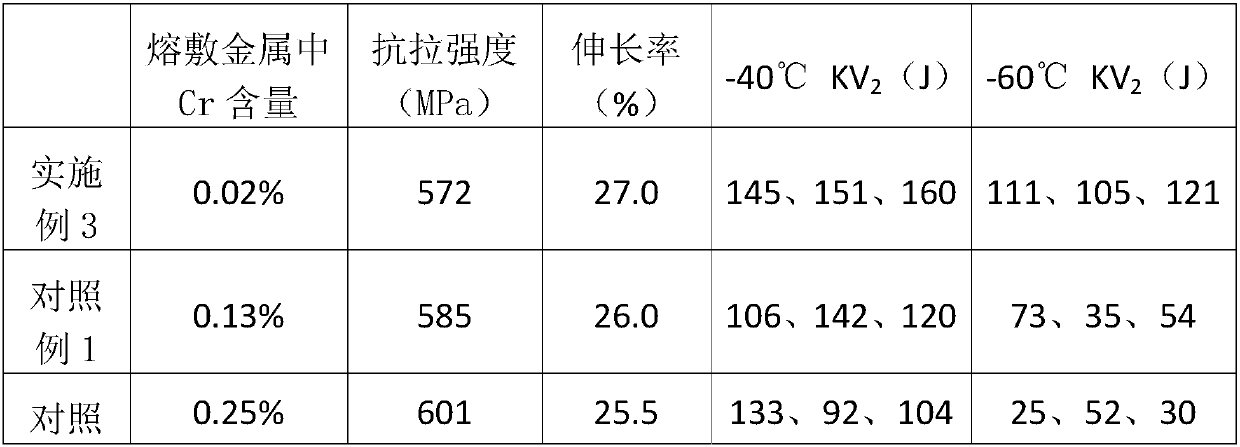

[0048] Experimental results:

[0049] The deposited metal of the flux cored wire satisfies that Cr accounts for 0.02% of the total mass of the total deposited metal. Flux cored wire deposit metal tensile strength 572MPa, yield strength 490MPa, elongation rate 27.0%, KV 2 (-60°C) 112J.

[0050] Corrosion resistance index I: 6.80.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com