Stainless steel electrode welding core with minimum temperature rise, stainless steel electrode and preparation and application

A technology of stainless steel and electrode welding, applied in the field of stainless steel electrode, preparation and application, and stainless steel electrode welding core, which can solve the problems of electrode waste, difficult operation, and high molybdenum content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

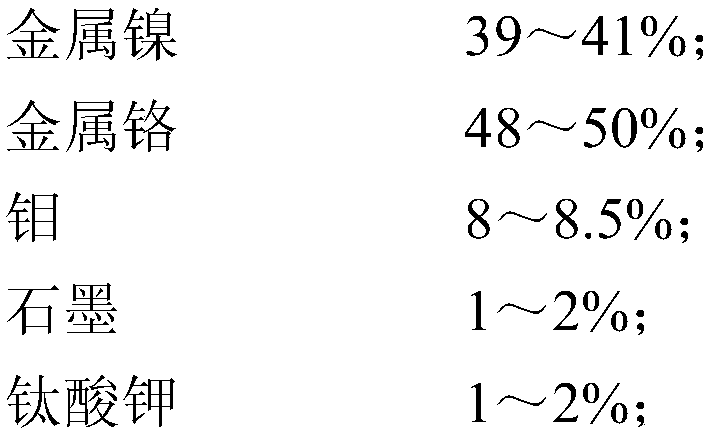

Method used

Image

Examples

Embodiment 1

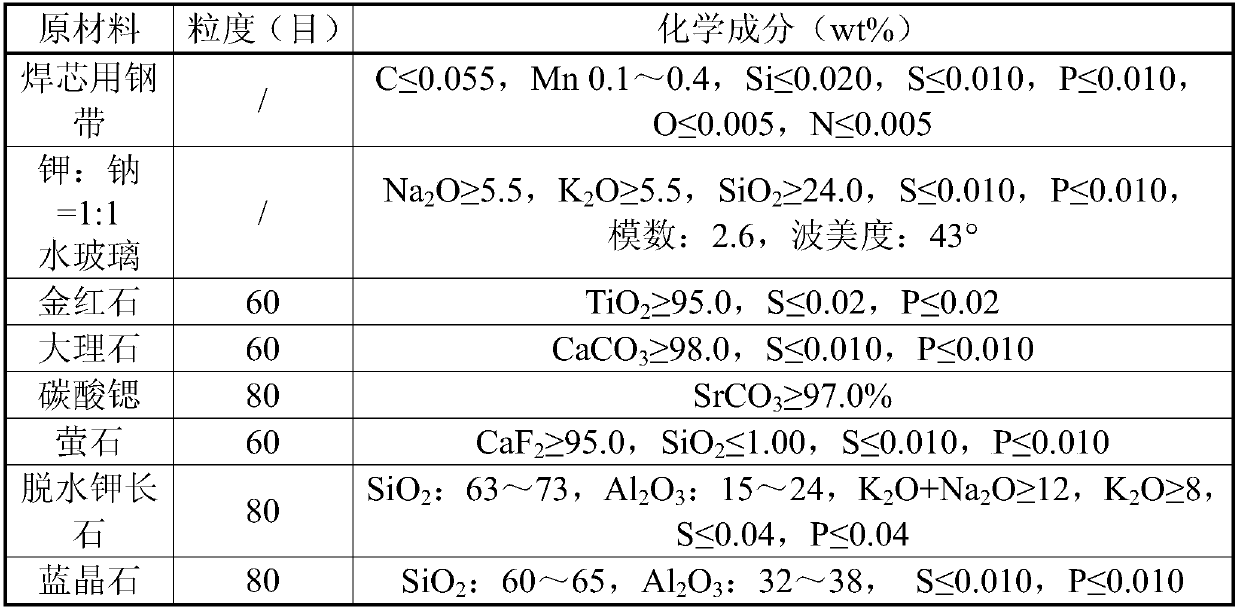

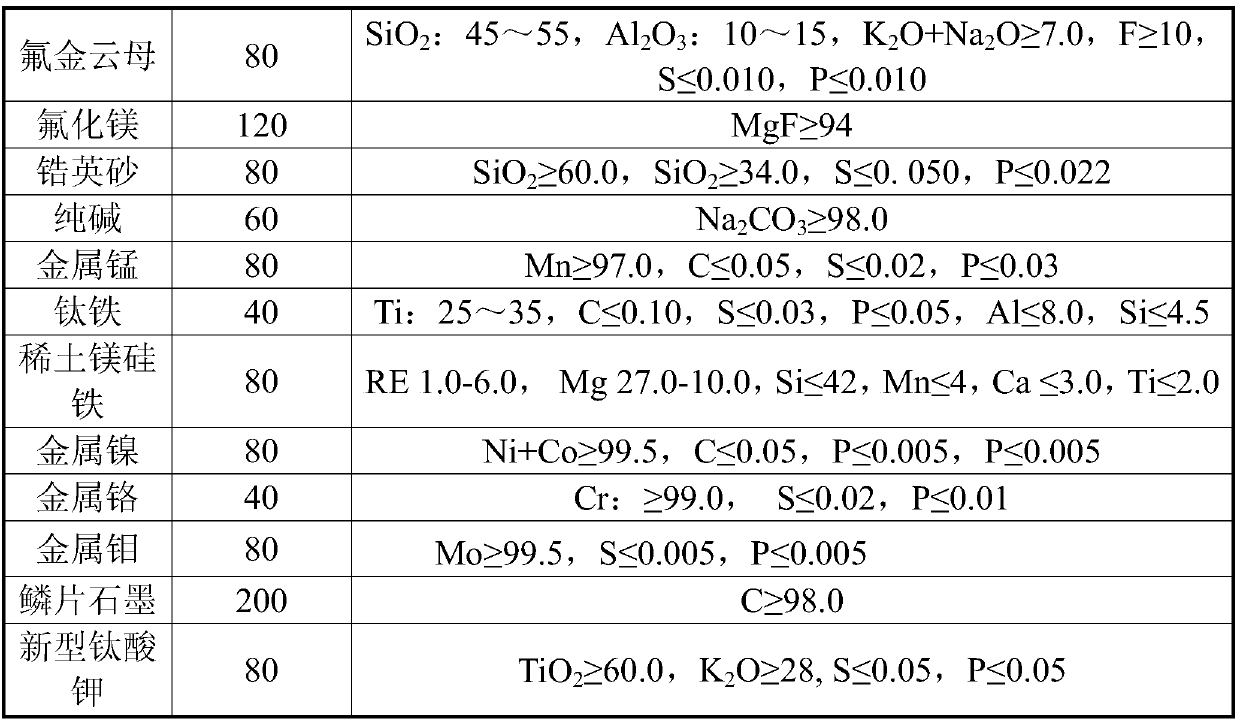

[0076] (1) Mix the components of the stainless steel electrode welding core with a very small temperature rise according to the ratio (see Table 1 for the chemical composition requirements of each component, and see A1 in Table 2 for the specific ratio) and stir evenly to obtain the powder core; then The low-carbon steel strip with the outer skin and the powder core are welded online on the seamless flux-cored wire production line to prepare a thick wire rod; after annealing and drawing, the diameter is reduced to a suitable diameter; finally, it is straightened and cut to obtain a very A stainless steel electrode welding core with a small temperature rise, wherein the filling rate of the powder core is 32wt%;

[0077] (2) Mix and stir the components of the skin dry powder (see Table 1 for the chemical composition requirements of each component, and see B1 in Table 3 for specific proportions), then add potassium with a total weight of 19% of the dry powder and a modulus of 2.6:...

Embodiment 2

[0080] The preparation method is the same as in Example 1, wherein, the solder core ratio is shown in Table 2 A1, the filling rate of the powder core is 32wt%; the coating dry powder ratio is shown in Table 3 B2, and the amount of binder is 19% of the total weight of the dry powder.

Embodiment 3

[0082] The preparation method is the same as in Example 1, wherein, the welding core ratio is shown in Table 2 A1, the filling rate of the powder core is 32wt%; the coating dry powder ratio is shown in Table 3 B3, and the amount of binder is 19% of the total weight of the dry powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com