Indium oxide-coated secondary aqueous neutral zinc ion battery positive electrode material and preparation method and application thereof

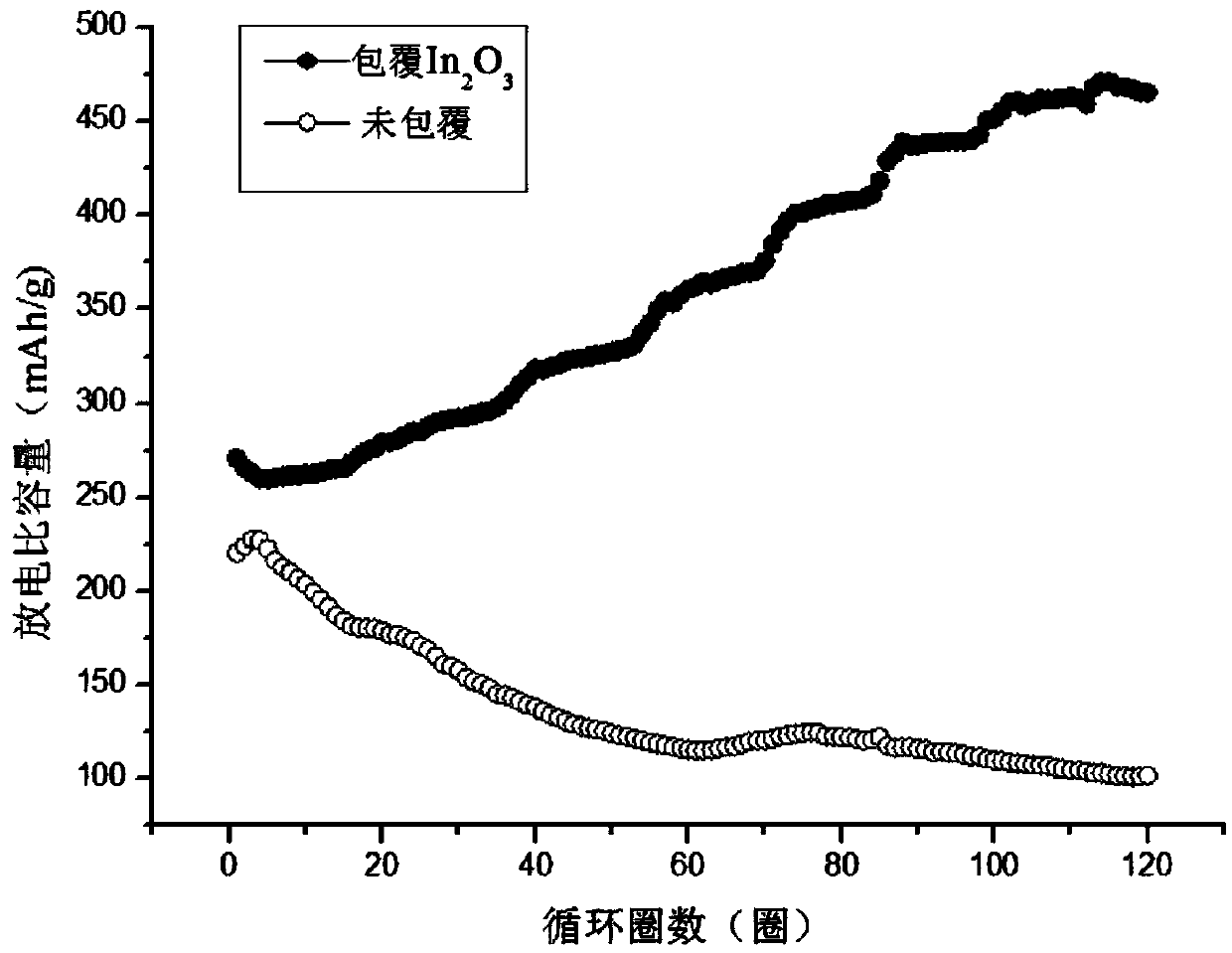

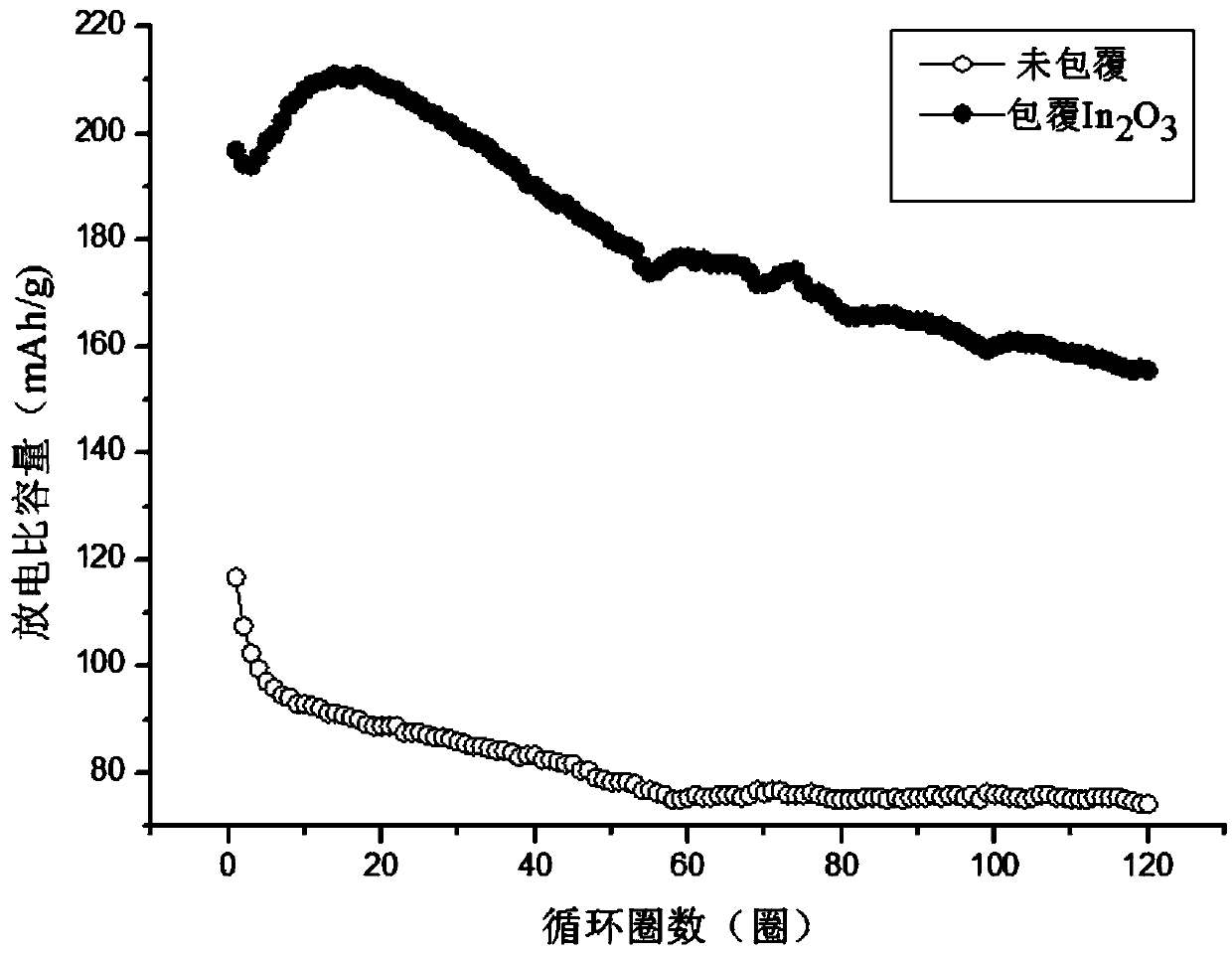

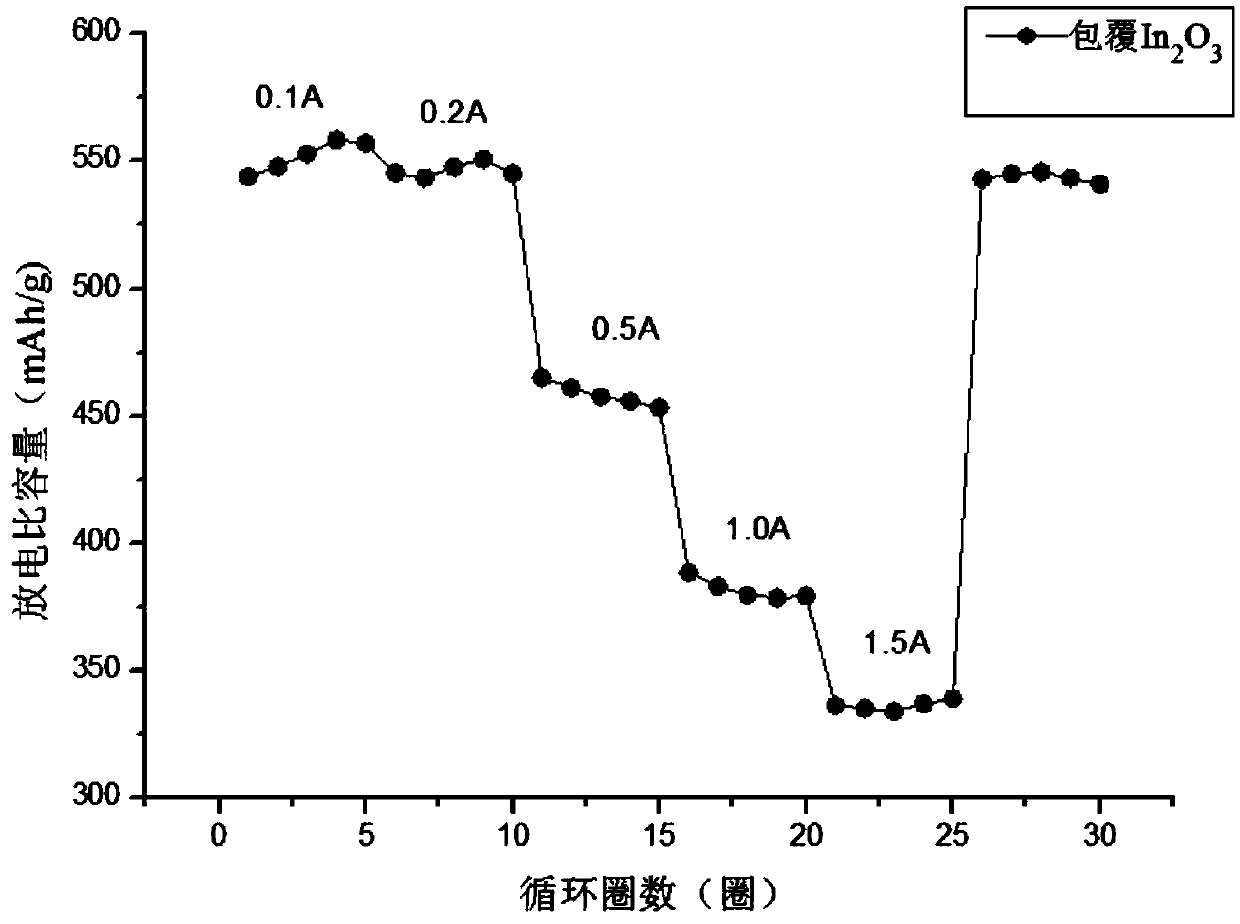

A technology of zinc ion battery and cathode material, applied in secondary batteries, battery electrodes, active material electrodes, etc., can solve the problems of poor electrical conductivity, low battery cycle and rate performance, etc., to improve rate performance and cycle stability. , the effect of good electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of indium oxide coated MnO 2 The preparation method of the water system zinc ion battery cathode material of nanorods comprises the following preparation steps:

[0039] Step 1, 0.7112g potassium permanganate (KMnO 4 ) was added to 70 mL of deionized water, and 3 mL of concentrated hydrochloric acid was added dropwise while stirring, and stirred for 30 min to obtain a mixed solution.

[0040] Step 2, transfer the mixed solution to a 100mL autoclave lined with polytetrafluoroethylene, conduct a hydrothermal reaction at 140°C for 16h, centrifuge, and wash with deionized water several times until no acidity is detected, then in Dry in a blast oven at 70°C for 12 hours and grind to obtain MnO 2 Nanorod precursors.

[0041] Step 3, take 0.4gMnO 2 The nanorod precursor was added into 55 mL of deionized water, and ultrasonically dispersed at 35° C. for 35 min to obtain a dispersion liquid of the positive electrode material of the zinc ion battery.

[0042] Step 4, ...

Embodiment 2

[0044] A kind of α-MnO coated with indium oxide 2 The preparation method of the water-based zinc ion battery cathode material of nanotubes comprises the following preparation steps:

[0045]Step 1, 0.395g potassium permanganate (KMnO 4 ) was added to 45 mL of deionized water, and 1 mL of concentrated hydrochloric acid was added dropwise while stirring, and stirred for 30 min to obtain a mixed solution.

[0046] Step 2, transfer the mixed solution to a 65mL autoclave lined with polytetrafluoroethylene, conduct a hydrothermal reaction at 140°C for 12h, centrifuge, and wash with deionized water several times until no acidity is detected, then in Dry in a blast drying oven at 70°C for 12 hours and grind to obtain α-MnO 2 Nanotube precursors.

[0047] Step 3, take 0.4g α-MnO 2 The nanotube precursor was added into 55 mL of deionized water, and ultrasonically dispersed at 20° C. for 60 min to obtain a zinc-ion battery cathode material dispersion.

[0048] Step 4, add 0.012g ind...

Embodiment 3

[0050] A kind of indium oxide coated β-MnO 2 The preparation method of the water system zinc ion battery cathode material of nanorods comprises the following preparation steps:

[0051] Step 1, 0.158g KMnO 4 and 0.253g MnSO 4 Add 15mL of deionized water, transfer to a 20mL small glass bottle, put it in a microwave oven for hydrothermal reaction, keep it at 200°C for 10 minutes, filter, wash with deionized water several times, and then dry it in a blast drying oven at 80 Dry at ℃ for 12h and grind to get β-MnO 2 Nanorod precursors.

[0052] Step 2, take 0.2g β-MnO 2 The nanorod precursor was added into 55 mL of deionized water, and ultrasonically dispersed at 50° C. for 10 min to obtain a zinc-ion battery cathode material dispersion.

[0053] Step 3, add 0.01g indium chloride (InCl 3 4H 2 O) and 0.23g polyvinylpyrrolidone (K-30), magnetically stirred for 2h, hydrothermally reacted at 160°C for 5h, centrifuged at 7000rpm for 15min, dried at 60°C for 11h, ground, and dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com