Transition metal chalcogenide compound horizontal homogeneous junction solar cell and preparation method thereof

A transition metal chalcogenide, solar cell technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of mismatch of work function between electrodes and thin films, inability to form good ohmic contact, stress and metal diffusion, etc. The effect of improving the lighting characteristics, reducing the interface defects and increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

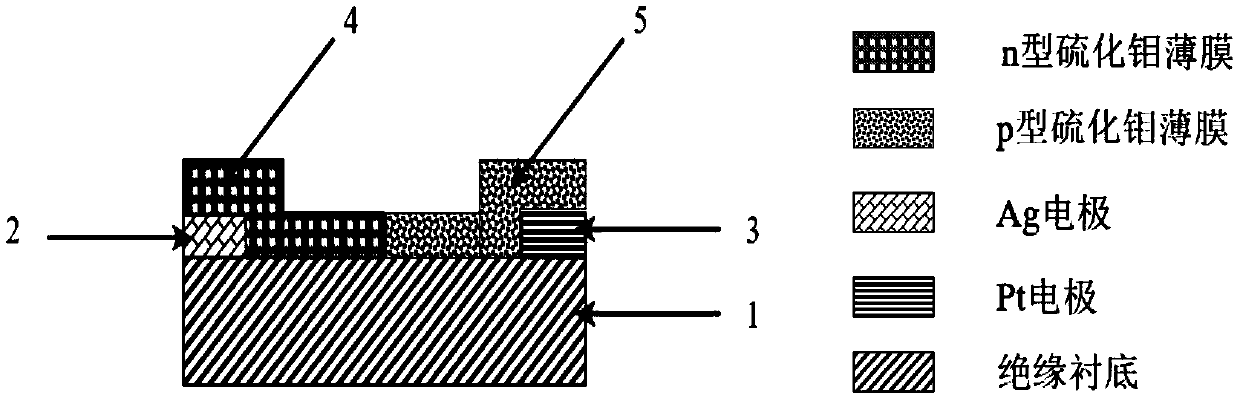

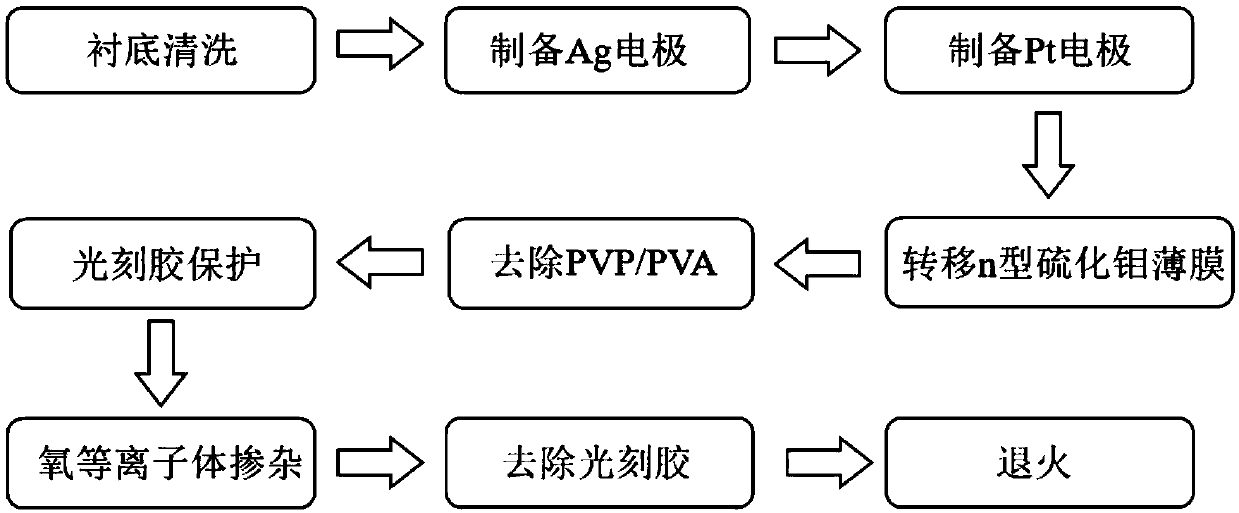

[0033] A method for preparing a transition metal chalcogenide film lateral homojunction of the present invention comprises the following steps:

[0034] (1) Electrode A is evaporated on one end of the insulating surface of the insulating substrate A, and electrode B is evaporated on the other end, and the electrode A and the electrode B are not in contact with each other to obtain a sample A;

[0035] (2) Prepare an n-type transition metal chalcogenide film on a silicon substrate B with a silicon dioxide insulating layer, spin-coat the sol on the n-type transition metal chalcogenide film, and then apply the colloid and the lower n-type transition The metal chalcogenide film is torn off, transferred to the sample A described in step (1), and then the sol is removed to obtain a sample B; the two ends of the n-type transition metal chalcogenide film are respectively located on the top of electrode A and electrode B, making part of the electrode A and at least part of the electrod...

Embodiment 1

[0057] The preparation method of the molybdenum sulfide film lateral homojunction solar cell provided by the present invention, the specific steps are as follows:

[0058] (1) Clean two silicon wafers with a silicon dioxide insulating layer on one side, and the thickness of the silicon dioxide insulating layer is 50 nm. Place it in deionized water, ultrasonically clean it for 3 minutes, then place it in acetone solution, ultrasonically clean it for 3 minutes, then place it in absolute ethanol, and ultrasonically clean it for 3 minutes. The two pieces are marked as A and B respectively.

[0059] (2) Place the mask of the corresponding Ag electrode structure on A, and use the electron beam evaporation process to evaporate the Ag electrode with a thickness of 10nm to obtain sample C;

[0060] (3) Place the mask of the corresponding Pt electrode structure on C, and use the electron beam evaporation process to evaporate the Pt electrode with a thickness of 10nm to obtain sample D; ...

Embodiment 2

[0069] The preparation method of the molybdenum sulfide film lateral homojunction solar cell provided by the present invention, the specific steps are as follows:

[0070] (1) Clean two silicon wafers with a silicon dioxide insulating layer on one side, and the thickness of the silicon dioxide insulating layer is 70 nm. Place it in deionized water, ultrasonically clean it for 5 minutes, then place it in acetone solution, ultrasonically clean it for 5 minutes, then place it in absolute ethanol, and ultrasonically clean it for 5 minutes. The two pieces are marked as A and B respectively.

[0071] (2) Place the mask of the corresponding Ag electrode structure on A, and use the electron beam evaporation process to vapor-deposit the Ag electrode with a thickness of 20nm to obtain sample C;

[0072] (3) Place the mask of the corresponding Pt electrode structure on C, and use the electron beam evaporation process to evaporate the Pt electrode with a thickness of 20nm to obtain sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com