Cellulose-molybdenum disulfide aerogel composite fiber and preparation method and application thereof

A molybdenum disulfide and composite fiber technology, applied in the field of composite fibers, can solve the problems of restricting the use environment of cellulose-based aerogels, the complexity and price of nanocellulose, and the preparation method has not yet been reported, and achieves the preparation of green, pollution-free, Low cost and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

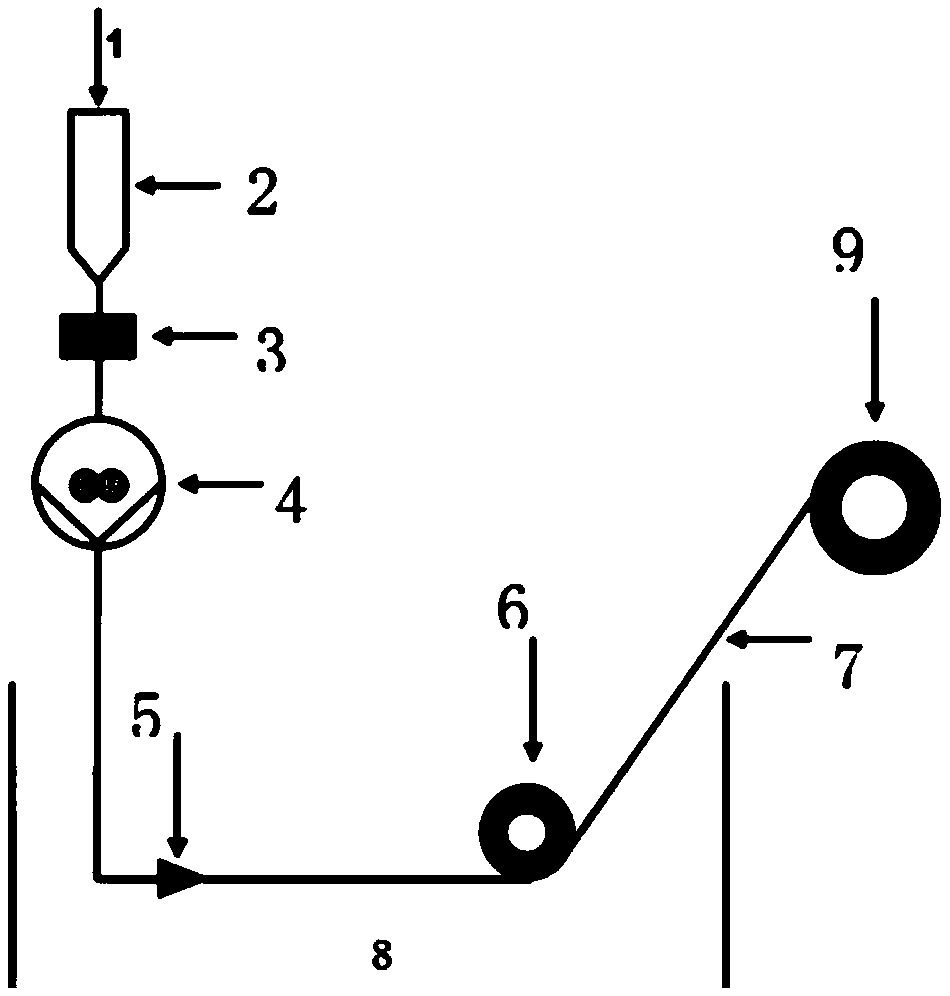

Method used

Image

Examples

Embodiment 1

[0043] (1) At a temperature of -12°C, put 0.5g cellulose into the sodium hydroxide / urea / water solution system, which is sodium hydroxide (mass fraction 7%), urea (mass fraction 12%) and water (mass fraction 81%) in a mixed solution system for 10 minutes to prepare a cellulose solution with a mass fraction of 0.5%.

[0044] (2) Molybdenum trioxide, thioacetamide and urea were respectively dissolved in water according to the mass ratio of 1:1:9, stirred evenly, and then the mixed solution was placed in a high-pressure reactor at 180°C for 18 hours, After the reaction, the product was washed to neutrality to obtain 1T metal phase molybdenum disulfide. Finally, an ultrasonic cleaner was used to oscillate and disperse 1T metal phase molybdenum disulfide in water at an ultrasonic oscillation amplitude of 20% for 10 minutes to obtain mass 1% 1T metallic phase molybdenum disulfide aqueous solution.

[0045](3) The cellulose solution and the 1T metal phase molybdenum disulfide aqueous...

Embodiment 2

[0049] (1) At the temperature of -15°C, put 4g cellulose into the sodium hydroxide / urea / water solution system, which is sodium hydroxide (mass fraction 7%), and urea (mass fraction 12%) and water (mass fraction 81%) %) in a mixed solution system for 20 minutes to obtain a cellulose solution with a mass fraction of 4%.

[0050] (2) respectively dissolving molybdenum trioxide, thioacetamide and urea in water according to the mass ratio of 1.2:1.2:10, stirring evenly, and then placing the mixed solution in an autoclave at 200°C for 20 hours, After the reaction, the product was washed to neutrality to obtain 1T metal phase molybdenum disulfide. Finally, an ultrasonic cleaner was used to oscillate and disperse 1T metal phase molybdenum disulfide in water at an ultrasonic oscillation amplitude of 80% for 60 minutes to obtain quality 1T metallic phase molybdenum disulfide aqueous solution with a fraction of 5%.

[0051] (3) The cellulose solution and the 1T metal phase molybdenum di...

Embodiment 3

[0055] (1) At a temperature of -20°C, put 2g of cellulose into the sodium hydroxide / urea / water solution system, which is sodium hydroxide (mass fraction 7%), and urea (mass fraction 12%) and water (mass fraction 81%) %) in a mixed solution system for 60 minutes to obtain a cellulose solution with a mass fraction of 2%.

[0056] (2) respectively dissolving molybdenum trioxide, thioacetamide and urea in water according to the mass ratio of 1.5:1.5:15, stirring evenly, then placing the mixed solution in an autoclave at 220° C. for 24 hours, After the reaction, the product was washed to neutrality to obtain 1T metal phase molybdenum disulfide. Finally, an ultrasonic cleaner was used to oscillate and disperse 1T metal phase molybdenum disulfide in water at an ultrasonic oscillation amplitude of 40% for 30 minutes to obtain mass 1T metallic phase molybdenum disulfide aqueous solution with a fraction of 10%.

[0057] (3) The cellulose solution and the 1T metal phase molybdenum disul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com