Red yeast rice passion fruit vinegar and gradient biological fermentation preparation method thereof

A technology of red yeast passion fruit and bio-fermentation, applied in the field of fruit processing, can solve the problems of low utilization rate of enzymatic hydrolysis raw materials, high pectin content, low saccharification and fermentation power of red yeast rice, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

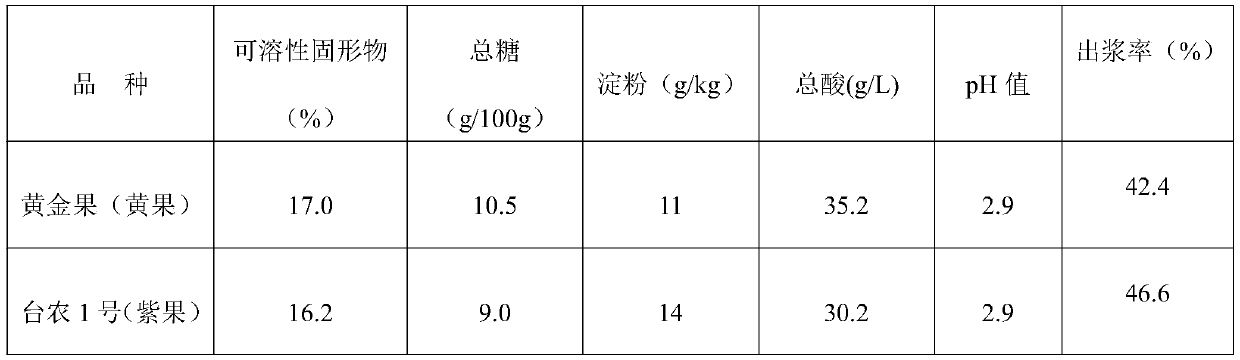

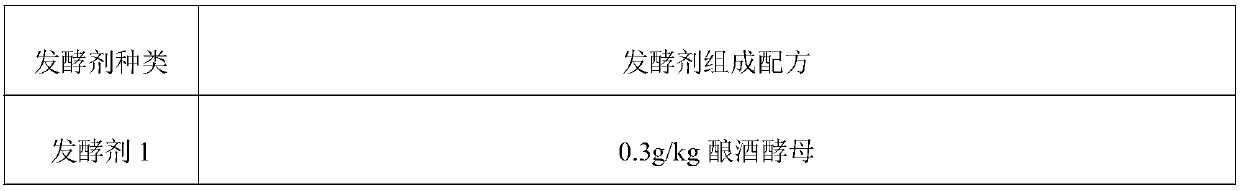

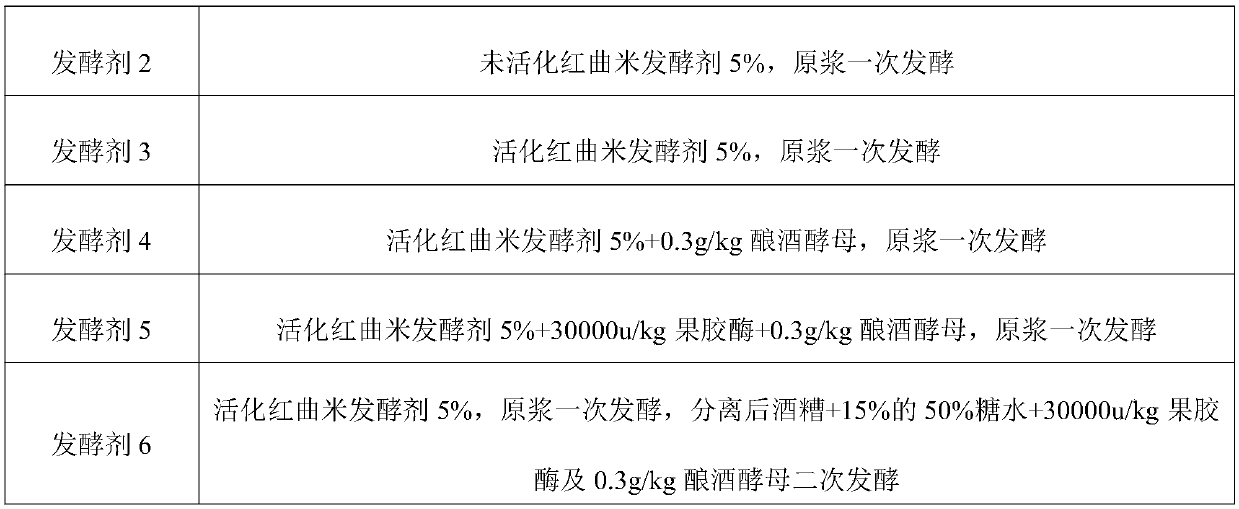

[0065] Prepare passion fruit vinegar with starter 1 in table 2 as starter

[0066] Fresh eight mature golden fruit (yellow fruit) and nine ripe Tainong No. 1 (purple fruit) passion fruit are cut open, the pericarp is removed, and passion fruit pulp is separated to obtain the passion fruit pulp juice, and the two kinds of passion fruit pulp juice are Mix at 1:1, pour the passion fruit pulp juice obtained after mixing into a biological fermentation tank, use 0.3g / kg Angel dry yeast as a starter, and ferment at 20-30°C for 20-30d, Add 5% acetic acid bacteria Shanghai Niang 1.01, control the fermentation temperature at 28-32°C in the acetification machine with corn cob as the carrier, ferment until the alcohol is basically converted into acetic acid, stop the fermentation, and ferment the new passion fruit vinegar obtained after acetic acid fermentation Seal it in a pottery jar and age it in a clean and cool environment for 6 months to get passion fruit vinegar.

Embodiment 2

[0068] Prepare passion fruit vinegar with starter 2 in table 2 as starter

[0069] The difference from Example 1 is that after the passion fruit pulp juice obtained after mixing is injected into the biological fermenter, 5% unactivated red yeast rice starter is used as the starter, and other process conditions and operating steps are the same as those in the implementation Example 1 is the same.

Embodiment 3

[0071] Prepare passion fruit vinegar with starter 3 in table 2 as starter

[0072] The difference from Example 1 is that after the passion fruit pulp juice obtained after mixing is injected into the biological fermenter, 5% activated red yeast rice starter is used as the starter, and other process conditions and operating steps are the same as those in Example 1. same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com