Flame-retardant polyurethane hot melt adhesive with excellent water resistance and preparation method of hot melt adhesive

A technology of polyurethane hot-melt adhesive and flame-retardant polyether, which is applied in the field of structural adhesives, can solve the problems of reducing the waterproof performance and chemical resistance of polyurethane hot-melt adhesive coatings, improve compatibility and solve solvent resistance. Performance, the effect of not easy to bubble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

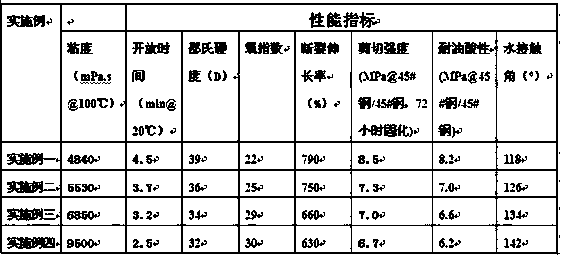

Examples

Embodiment 1

[0028] It is a flame-retardant polyurethane hot-melt adhesive with excellent waterproof performance, which is prepared by the following steps:

[0029] Step 1: Synthesis of hydroxyl-terminated phosphorus-containing flame-retardant polyacrylic acid fluorinated copolymer

[0030] 6 parts of trifluoroethyl acrylate TFMA, 15 parts of methyl methacrylate MMA, 25 parts of methoxyethyl methacrylate MEMA and 10 parts of 2-methyl-2-acrylic acid-2-hydroxyethyl Base ester phosphate ester HMP was dissolved in 50 parts of toluene, controlled at 60°C, under nitrogen protection, 2.8 parts of thermal initiator 4,4'-azobis(4-cyanopentanol) was added, polymerization reaction 8 Hours, after the toluene is removed by rotary evaporation, the hydroxyl-terminated phosphorus-containing flame-retardant polyacrylic acid fluorine-containing copolymer is obtained, and the hydroxyl-terminated phosphorus-containing flame-retardant polyacrylic acid fluorine-containing copolymer contains an average of 1 to 2...

Embodiment 2

[0034] It is a flame-retardant polyurethane hot-melt adhesive with excellent waterproof performance, which is prepared by the following steps:

[0035] Step 1: Synthesis of hydroxyl-terminated phosphorus-containing flame-retardant polyacrylic acid fluorinated copolymer

[0036] 12 parts of trifluoroethyl acrylate TFMA, 15 parts of methyl methacrylate MMA, 20 parts of methoxyethyl methacrylate MEMA and 15 parts of 2-methyl-2-acrylic acid-2-hydroxyethyl Base ester phosphate HMP was dissolved in 80 parts of toluene, controlled at 65°C, under the protection of nitrogen, 1.3 parts of thermal initiator 4,4'-azobis(4-cyanopentanol) was added, and the polymerization reaction was 10 Hours, after the toluene is removed by rotary evaporation, the hydroxyl-terminated phosphorus-containing flame-retardant polyacrylic acid fluorine-containing copolymer is obtained, and the hydroxyl-terminated phosphorus-containing flame-retardant polyacrylic acid fluorine-containing copolymer contains an av...

Embodiment 3

[0040] It is a flame-retardant polyurethane hot-melt adhesive with excellent waterproof performance, which is prepared by the following steps:

[0041] Step 1: Synthesis of hydroxyl-terminated phosphorus-containing flame-retardant polyacrylic acid fluorinated copolymer

[0042] 16 parts of trifluoroethyl acrylate TFMA, 27 parts of methyl methacrylate MMA, 17 parts of methoxyethyl methacrylate MEMA and 22 parts of 2-methyl-2-acrylic acid-2-hydroxyethyl The base ester phosphate HMP was dissolved in 90 parts of toluene, controlled at 75°C, and under the protection of nitrogen, 0.6 parts of thermal initiator 4,4'-azobis(4-cyanopentanol) was added, and the polymerization reaction was 14 Hours, after the toluene is removed by rotary evaporation, the hydroxyl-terminated phosphorus-containing flame-retardant polyacrylic acid fluorine-containing copolymer is obtained, and the hydroxyl-terminated phosphorus-containing flame-retardant polyacrylic acid fluorine-containing copolymer contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com