Oil adhesion-control antifouling self-cleaning fluoride-free coating and preparation method

A self-cleaning and antifouling technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problem of reducing oil adhesion, increasing energy consumption, and time-consuming wedge-shaped micro-nano structure surface construction, etc. problems, to achieve the effect of increasing mechanical properties, improving mechanical properties, and high surface enrichment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

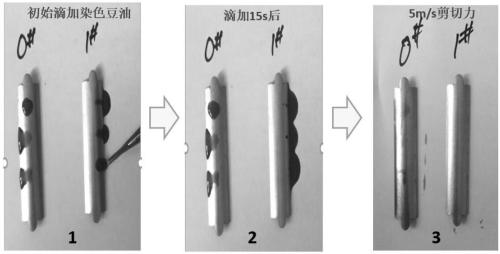

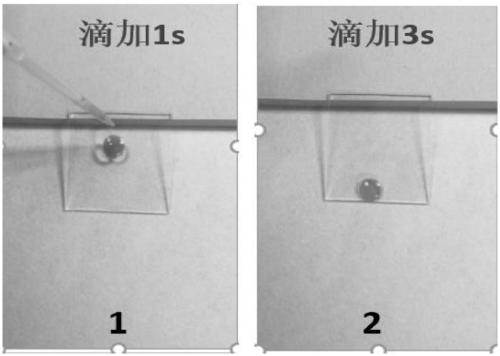

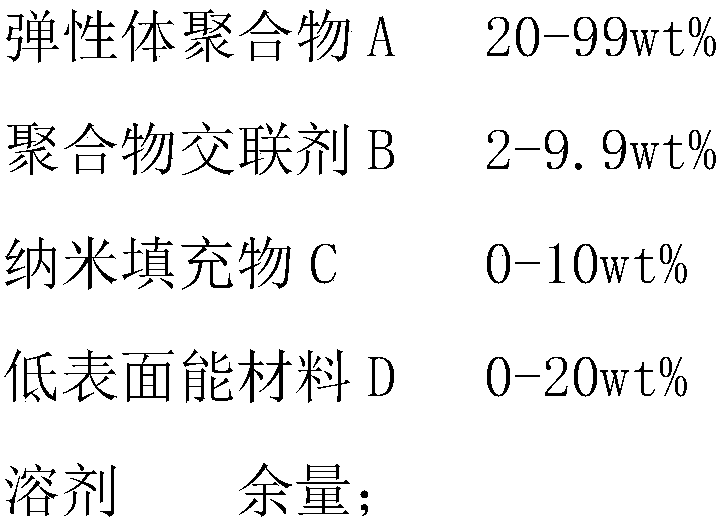

[0037] Weigh PDMS prepolymer A (100g) and B (10g) crosslinking agent ( 184 or RBB-2060-50 phenyl silicone rubber), 0.5 grams of graphene, and 0.1 grams of trimethoxyundecylsilane were dissolved in 500 mL of tetrahydrofuran, and stirred thoroughly to obtain a precursor polymerization solution; the surface of the stainless steel metal plate was cleaned with ethanol, Air-dry, brush the precursor polymerization solution on the surface of a clean stainless steel metal plate, incubate at 80°C for 4 hours, and then dry it naturally to achieve an oil-controlling, anti-fouling, self-cleaning, fluorine-free coating on the surface of the stainless steel metal plate.

Embodiment 2

[0039] Weigh PDMS prepolymer A (100g) and B (10g) crosslinking agent ( 184 or RBB-2060-50 phenyl silicone rubber), 1.0 g of graphene, 0.1 g of trimethoxyundecylsilane were dissolved in 500 mL of tetrahydrofuran, fully stirred and mixed to obtain a precursor polymerization solution; the surface of the stainless steel metal plate was cleaned with ethanol, Air-dry, brush the precursor polymerization solution on the surface of a clean stainless steel metal plate, incubate at 80°C for 4 hours, and then dry it naturally to achieve an oil-controlling, anti-fouling, self-cleaning, fluorine-free coating on the surface of the stainless steel metal plate.

Embodiment 3

[0041] Weigh PDMS prepolymer A (100g) and B (10g) crosslinking agent ( 184 or RBB-2060-50 phenyl silicone rubber), 2.0 grams of graphene, and 0.4 grams of trimethoxyundecylsilane were dissolved in 500 mL of tetrahydrofuran, and fully stirred and mixed to obtain a precursor polymerization solution; the surface of the stainless steel metal plate was cleaned with ethanol, Air-dry, brush the precursor polymerization solution on the surface of a clean stainless steel metal plate, incubate at 80°C for 4 hours, and then dry it naturally to achieve an oil-controlling, anti-fouling, self-cleaning, fluorine-free coating on the surface of the stainless steel metal plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com