Self-repairing anticorrosive coating and preparation method thereof

An anti-corrosion coating and automatic repair technology, applied in anti-corrosion coatings, coatings, epoxy coatings, etc., can solve the problems of poor coating compatibility, large amount of nanoparticles, easy to damage the integrity of the coating, etc. Corrosion, Compatibility Enhancement Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

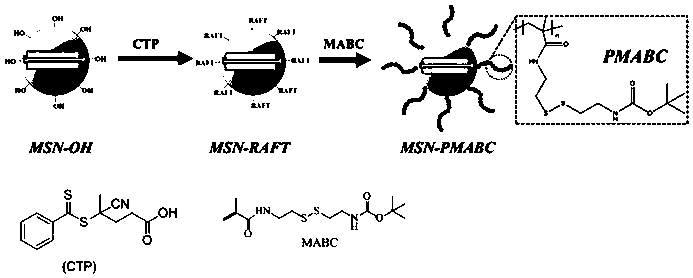

[0054] Schematic diagram of the preparation of stimuli-responsive mesoporous silica and the chemical structures of the main reagents such as figure 1 shown.

[0055] A self-healing anti-corrosion coating, including the following parts

[0056] (1) Stimuli-responsive mesoporous silica loaded with corrosion inhibitor 0.5-5 parts by weight

[0057] (2) Cured resin 95-99.5 parts by weight.

[0058] The resin cured product is formed by curing epoxy resin, epoxy curing agent and water.

[0059] The epoxy resin is bisphenol A type epoxy resin, and the epoxy curing agent is polyetheramine D230 and n-decylamine.

[0060] The cured resin is a cured polyurethane formed by curing a hydroxyl-containing resin, an isocyanate curing agent and water.

[0061] The stimuli-responsive mesoporous silica loaded with a corrosion inhibitor is composed of a corrosion inhibitor and a stimuli-responsive mesoporous silica, the corrosion inhibitor is located in the pore structure of the stimuli-respon...

Embodiment 1

[0091] A method for preparing an automatically repairable anti-corrosion coating, comprising the following steps:

[0092] (1) Preparation of mesoporous silica as a nano container;

[0093] (1a): Dissolve 10g of dodecyltrimethylammonium bromide and 5g of sodium hydroxide in 5L of water to obtain an alkaline aqueous solution; slowly drop 50mL of tetraethyloxysilane into the above alkaline aqueous solution, and react at a constant temperature under stirring 4h, the reaction temperature was 70°C; centrifuged, washed and dried to obtain mesoporous silica microspheres MSN;

[0094] (1b): Disperse mesoporous silica microspheres MSN in toluene solution, add silane coupling agent-glycidyl ether propyl trimethoxysilane drop by drop, reflux reaction for 12h, centrifuge, wash and dry to obtain ring Oxygen-modified mesoporous silica microspheres (MSN-epoxy);

[0095] The weight ratio of mesoporous silica microspheres to glycidyl ether propyl trimethoxysilane is 0.5:1;

[0096] (1c): Disp...

Embodiment 2

[0105] A method for preparing an automatically repairable anti-corrosion coating, comprising the following steps:

[0106] (1) Preparation of mesoporous silica as a nano container;

[0107] (1a): Dissolve 15g of dodecyltrimethylammonium bromide and 6g of sodium hydroxide in 5L of water to obtain an alkaline aqueous solution; slowly drop 100mL of tetraethyloxysilane into the above alkaline aqueous solution, and react at a constant temperature under stirring 4.5h, the reaction temperature is 75°C; centrifuge, wash and dry to obtain mesoporous silica microspheres MSN;

[0108] (1b): Disperse mesoporous silica microspheres MSN in toluene solution, add silane coupling agent-glycidyl ether propyl trimethoxysilane drop by drop, reflux reaction for 13h, centrifuge, wash and dry to obtain ring Oxygen-modified mesoporous silica microspheres (MSN-epoxy);

[0109] The weight ratio of mesoporous silica microspheres to glycidyl ether propyl trimethoxysilane is 1.0:1;

[0110] (1c): Dispe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com