Thermal-insulation material and preparation method thereof

A thermal insulation material and powder technology, applied in the field of thermal insulation material and its preparation, can solve problems such as product burns, achieve product filling, good performance, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The insulation material of this embodiment is prepared by the following steps:

[0031] ①Batching: each component is taken by weighing according to the following weight ratio: sodium chloride: 65%. Magnesium oxide: 30%, graphite powder: 5%;

[0032] 2. Mixing: mix the materials in step 1. evenly, then pour the sum of each component into 5% polyvinyl alcohol aqueous solution (mass percentage) with a concentration of 8%, and continue mixing and grinding for 10 minutes;

[0033] ③Granulation: granulate the material obtained in step ②;

[0034] ④Compressing: Press and shape the granulated material in step ③ on a hydraulic press to obtain a semi-finished product;

[0035] ⑤Heat treatment: put the semi-finished product into a vacuum furnace for heat treatment, the heat treatment temperature is 680°C, and the vacuum degree is 10 - 3 MPa, the treatment time is 1 hour, and then cooled to room temperature with the furnace to obtain the finished product.

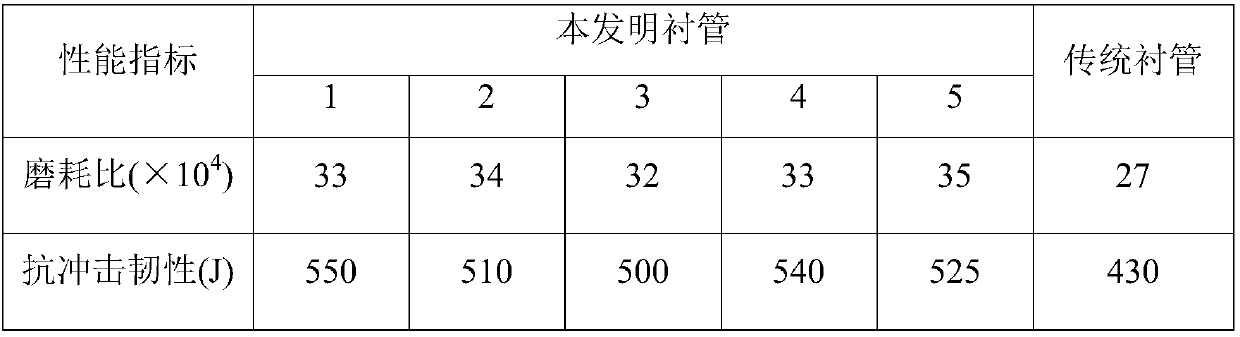

[0036] Using this m...

Embodiment 2

[0039] The high-efficiency thermal insulation liner of this embodiment is prepared by the following steps:

[0040] 1. Ingredients: each component is weighed according to the following weight ratio: sodium chloride: 80%. Zirconia: 10%, graphite powder: 10%;

[0041] 2. Mixing: mix the materials in step 1. evenly, then pour the sum of each component into 5% polyvinyl alcohol aqueous solution (mass percentage) with a concentration of 8%, and continue mixing and grinding for 10 minutes;

[0042] ③Granulation: granulate the material obtained in step ②;

[0043] ④Compressing: Press and shape the granulated material in step ③ on a hydraulic press to obtain a semi-finished product;

[0044] ⑤Heat treatment: put the semi-finished product into a vacuum furnace for heat treatment, the heat treatment temperature is 680°C, and the vacuum degree is 10 - 3 MPa, the treatment time is 1 hour, and then cooled to room temperature with the furnace to obtain the finished product.

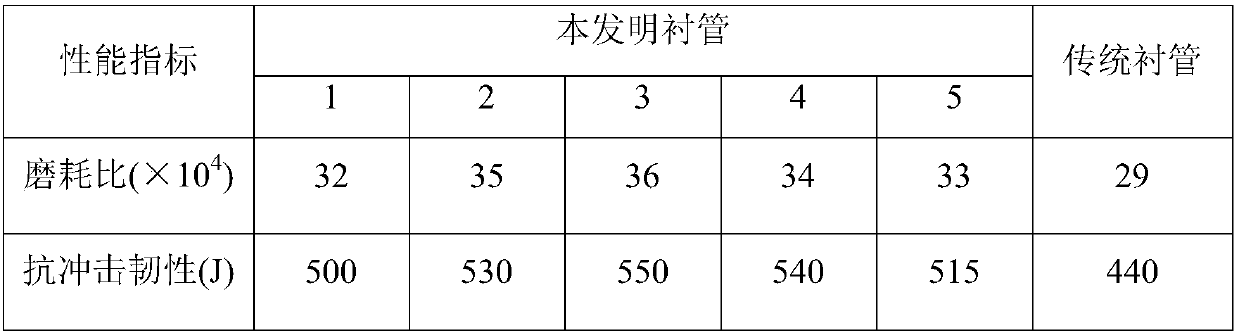

[0045] Us...

Embodiment 3

[0048] The high-efficiency thermal insulation liner of this embodiment is prepared by the following steps:

[0049] ①Batching: each component is weighed according to the following weight ratio: sodium chloride: 70%. Magnesium oxide: 20%, graphite powder: 8%, aluminum powder 2%;

[0050] 2. Mixing: mix the materials in step 1. evenly, then pour the sum of each component into 5% polyvinyl alcohol aqueous solution (mass percentage) with a concentration of 8%, and continue mixing and grinding for 10 minutes;

[0051] ③Granulation: granulate the material obtained in step ②;

[0052] ④Compressing: Press and shape the granulated material in step ③ on a hydraulic press to obtain a semi-finished product;

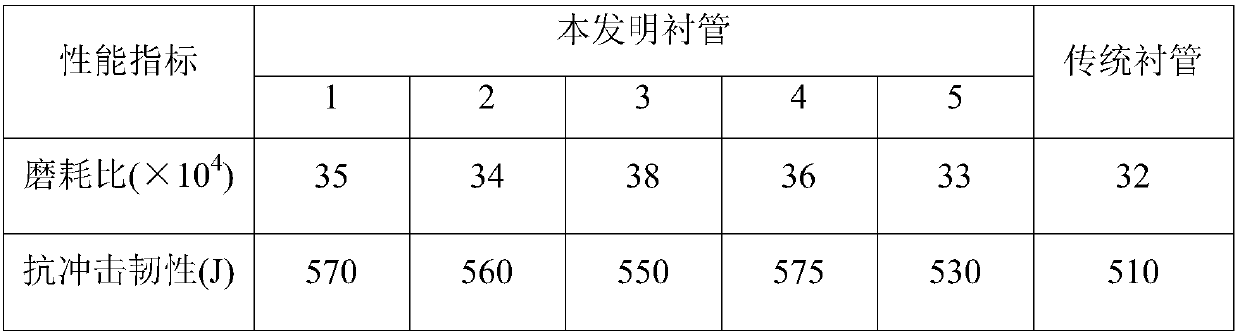

[0053] ⑤Heat treatment: put the semi-finished product into a vacuum furnace for heat treatment, the heat treatment temperature is 680°C, and the vacuum degree is 10 - 3 MPa, the treatment time is 1 hour, and then cooled to room temperature with the furnace to obtain the finished ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com