Design method of electrostatic dust removal reactor and indoor dust removal equipment

A technology of electrostatic dust removal and design method, which is applied in the field of air purification, can solve problems such as ineffective removal, and achieve the effect of improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

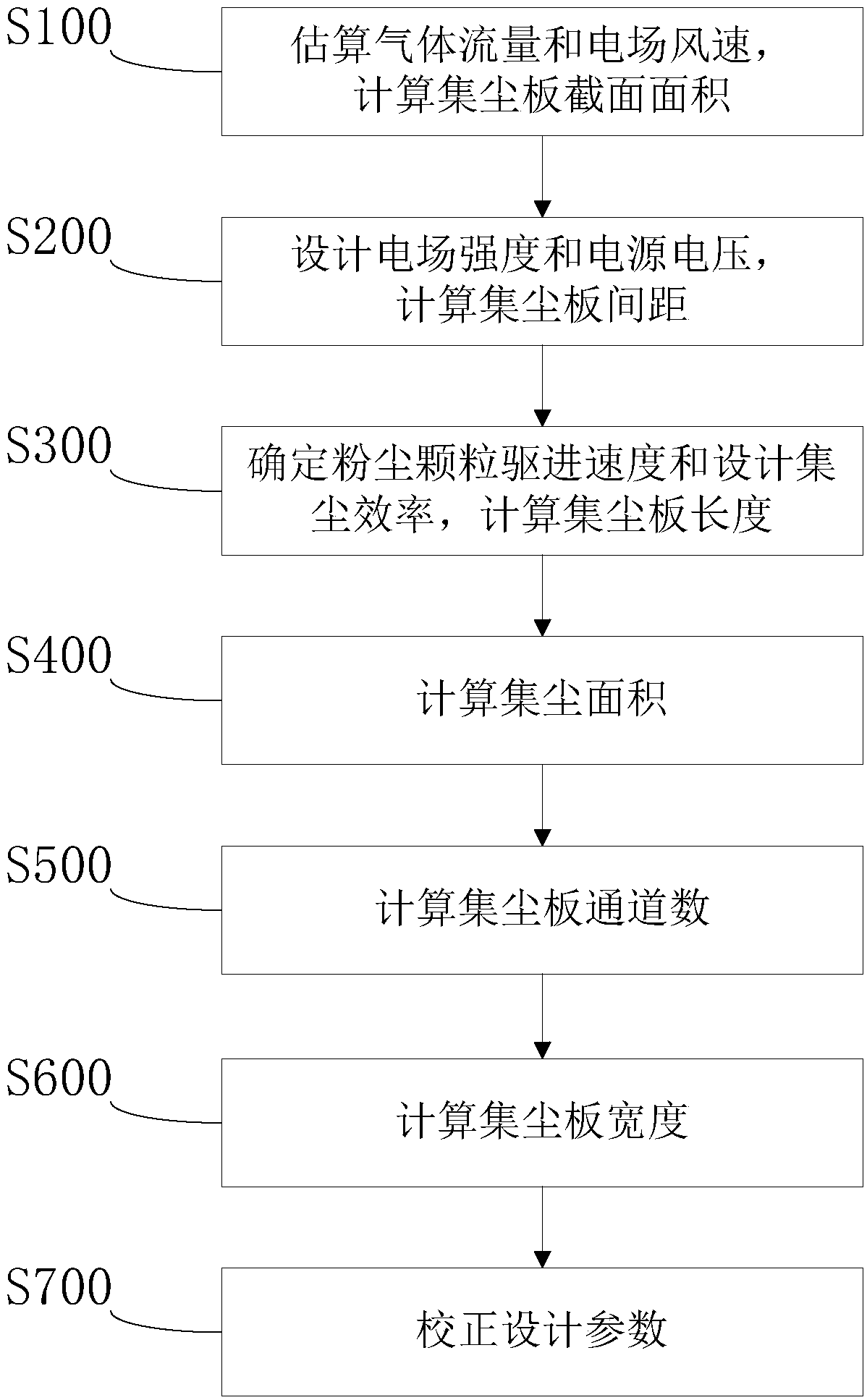

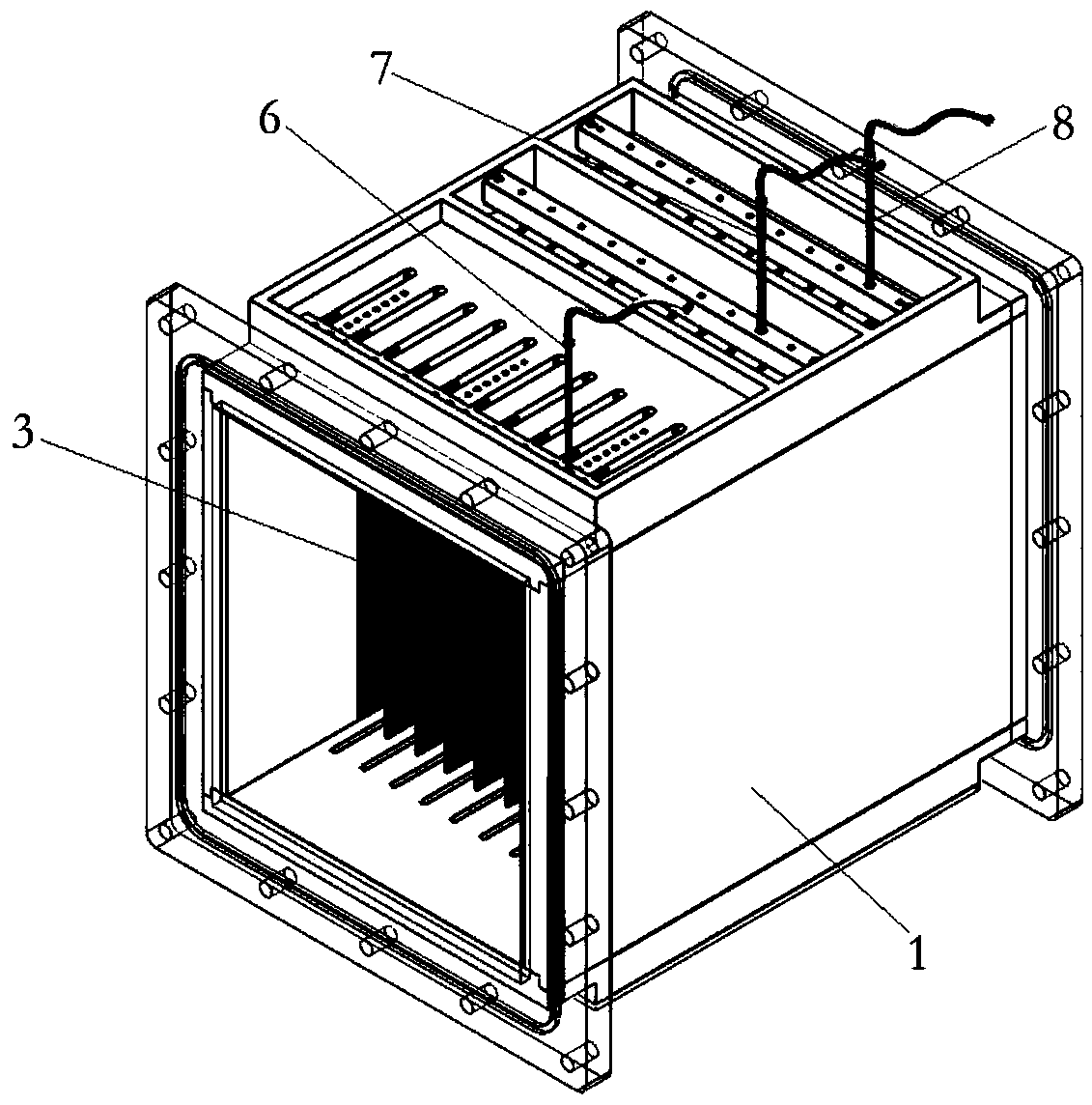

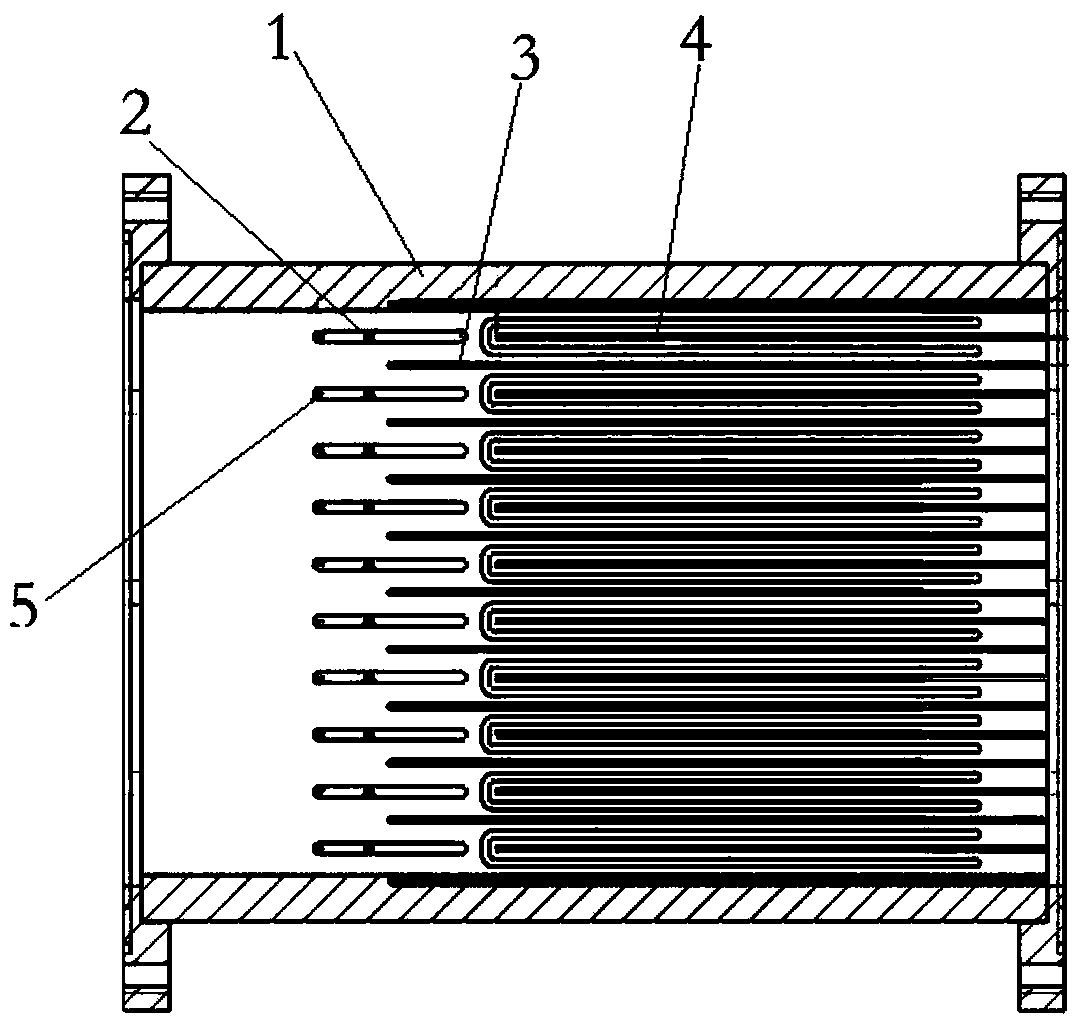

[0048] An electrostatic dust removal reactor has a wire-plate electric field structure and adopts positive corona discharge. The electric field structure design method is as follows: figure 1 shown, including the following steps:

[0049] S100: Estimate the indoor gas flow Q and the electric field wind speed V, and calculate the cross-sectional area F of the high voltage plate according to the gas flow Q and the electric field wind speed V,

[0050] S200: Design the electric field strength E and the power supply voltage U, calculate the high-voltage plate spacing b,

[0051] S300: Determine the dust particle driving speed ω and the design dust collection efficiency η', and calculate the length L of the high-voltage plate according to the efficiency formula, the efficiency formula is:

[0052]

[0053]Among them, η' is the design dust collection efficiency, ω is the driving speed of dust particles, V is the wind speed of the electric field, b is the distance between the...

Embodiment 2

[0063] Design an electrostatic precipitator reactor, including the following steps:

[0064] S100: Estimate the indoor gas flow Q, set the room area S, height H, air circulation times N per hour, and substitute into the formula Q=S×H×N to obtain the required gas flow Q.

[0065] The wind speed V of the electric field of the electrostatic precipitator is taken as 1-1.5m / s. If the wind speed of the dust collector is too high, the length of the electric field and the volume of the purifier will be increased, causing the dust to fly again; if the wind speed is too low, the cross-sectional area of the electric field will increase. Thereby the volume of equipment increases, and the cost rises.

[0066] Calculate the cross-sectional area F of the high-voltage plate according to the gas flow Q and the wind speed V of the electric field, and substitute it into the formula

[0067] S200: The design electric field strength E is 3-8kV / cm, the power supply voltage U is 5-7kV, and the ...

Embodiment 3

[0081] Design an electrostatic precipitator reactor, including the following steps:

[0082] S100: Estimate the indoor gas flow Q, and set the room area S to 10m 2 , the height H is 3m, the number of air circulation per hour N is 3 times, and the formula Q=S×H×N is substituted into the required gas flow Q to be 90m 3 / h. Set the electric field wind speed V of the electrostatic precipitator to 1m / s.

[0083] Calculate the cross-sectional area F of the high-voltage plate according to the gas flow Q and the wind speed V of the electric field, and substitute it into the formula The cross-sectional area F of the high-voltage plate is 0.025m 2 .

[0084] S200: The design electric field strength E is 5kV / cm, the power supply voltage U is 7kV, and the distance between the high voltage plates is calculated The obtained high-voltage plate spacing b is 14mm.

[0085] S300: According to empirical values, determine that the driving speed w is 0.09m / s, set the design dust collection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com