Brass waste processing and recycling technology

A technology of brass waste and process, which is applied in the direction of grain processing, process efficiency improvement, and separation of solids from solids with air flow, etc., which can solve the problems of low quality of recycled products, low degree of automation, and high labor costs. Achieve the effects of centralized management, high degree of automation, and improvement of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

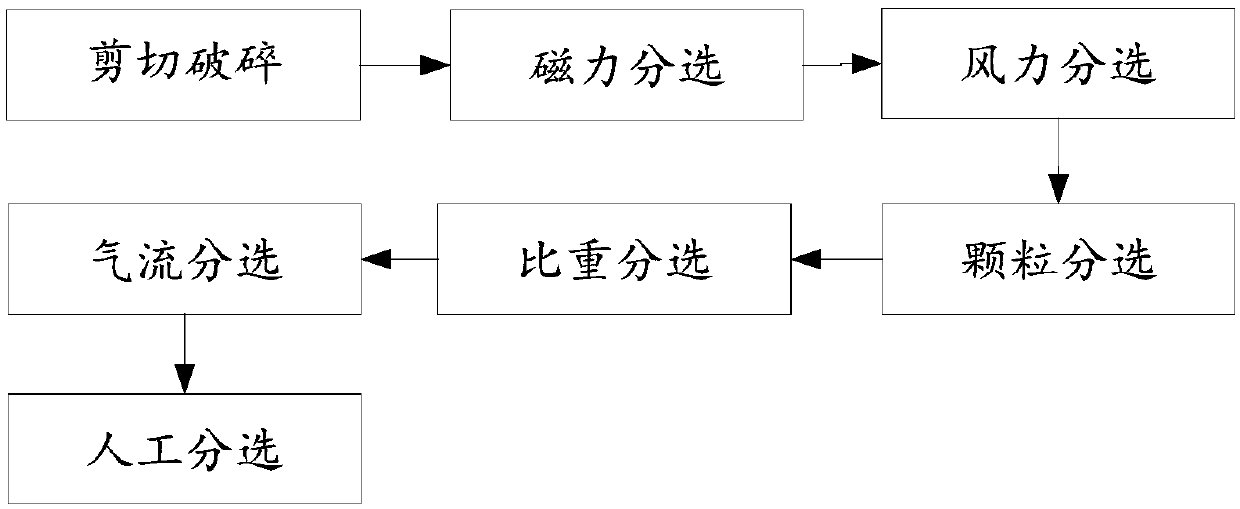

[0024] In this example, refer to figure 1 , This embodiment provides a treatment and recycling process for brass waste, which mainly includes steps including shear crushing, magnetic sorting, wind sorting, particle sorting, specific gravity sorting, airflow sorting, and manual sorting. Specifically, the method of each process step is as follows:

[0025] (1) Shearing and breaking:

[0026] Due to the different sizes of brass scraps in life, some brass scraps are relatively large in size, so the brass scraps need to be cut and broken first. Preferably, in this embodiment, a shearing machine is used to first cut the brass waste, and then the cut brass waste is added to a crusher, and the brass waste is crushed to a particle size below 40mm by the crusher. Then the crushed materials are transported to the magnetic separation system, so that the materials can be magnetically separated in the next process.

[0027] (2) Magnetic separation:

[0028] Since the brass waste contain...

Embodiment 2

[0042] On the basis of Embodiment 1, the crusher in the shearing and crushing step in this embodiment can use a single-roll crusher and a hammer crusher; the single-roll crusher is used for primary crushing of the brass waste; The hammer crusher is used for secondary crushing of the primary crushed brass scrap. By crushing the brass scrap twice to make the brass scrap reach the required size.

Embodiment 3

[0044] On the basis of Embodiment 1, in the magnetic separation step in this embodiment, a belt-type iron remover is installed above the conveyor belt, and the iron remover can be a magnet with strong magnetic force. , the iron remover will absorb the magnetic metal substances in the crushed materials, thereby separating the magnetic metal substances and non-magnetic substances. Preferably, the magnetic metal substances separated in the magnetic separation step include finished iron and iron-containing materials, and the finished iron is for direct sale.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com