Raw material air pretreatment method

A pretreatment and air technology, applied in gas treatment, auxiliary pretreatment, separation methods, etc., can solve problems such as accumulation, increase in energy costs, and impact on reaction systems, and achieve the goals of increasing air temperature, saving steam, and increasing water content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

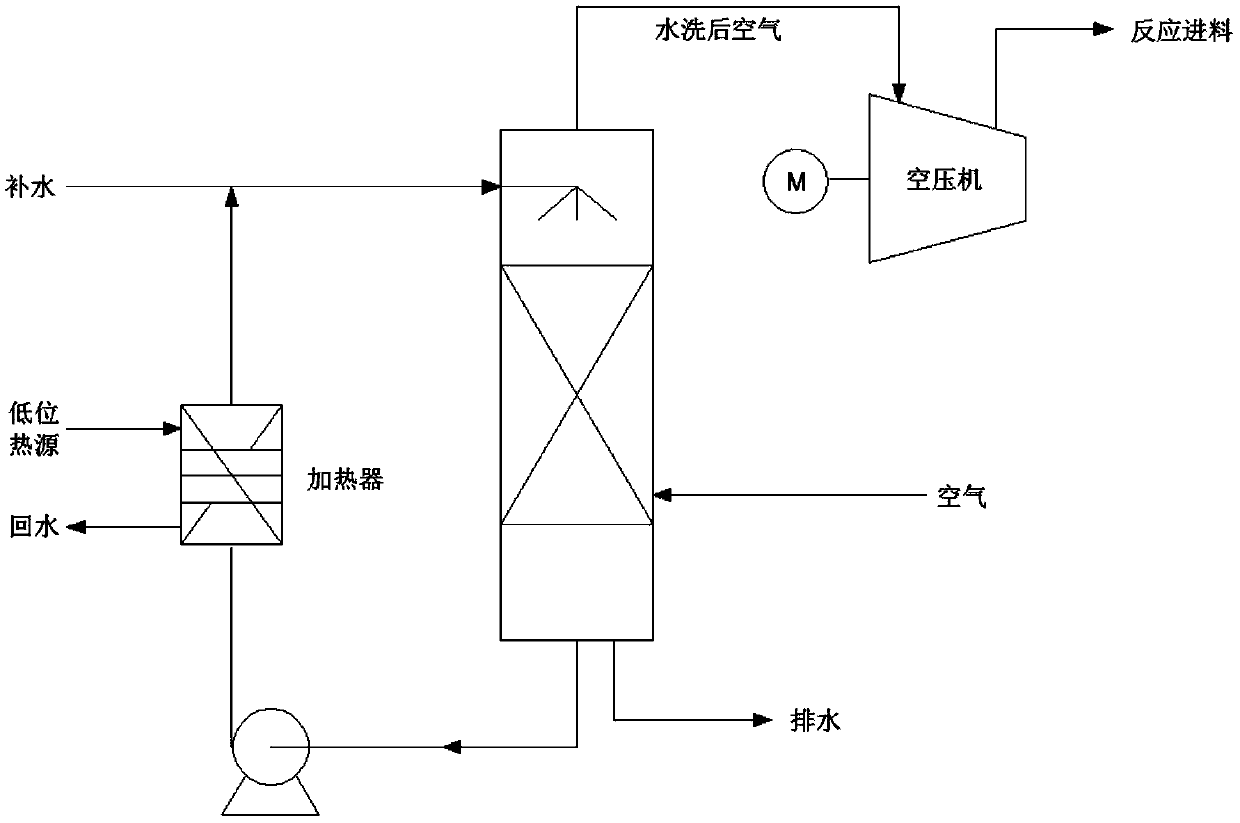

Method used

Image

Examples

Embodiment 1

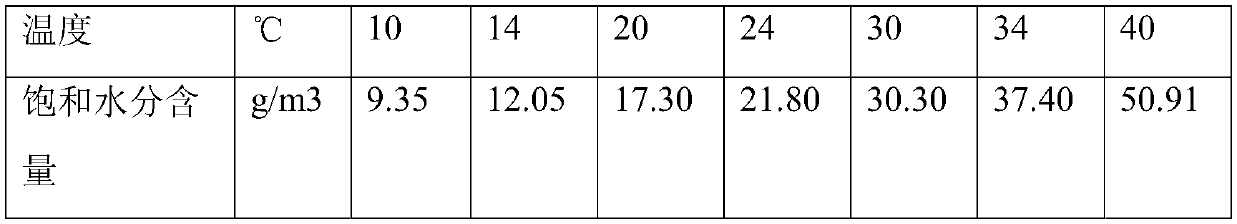

[0021] The air into the packed tower is 170t / h, 10℃, water content 0.82vol%; the supplementary water is steam condensed water in the device, 2.5t / h, 95℃; the low-level heat source is hot water in the device, 40t / h, 80℃, return water The temperature is 31.3°C; the air temperature after water washing is 24.8°C, and the water content is 3.1vol%; low-grade heat recovery is 1.89Gcal / h.

Embodiment 2

[0023] The air into the packed tower is 170t / h, 10℃, water content 0.82vol%; the supplementary water is steam condensed water in the device, 2.8t / h, 90℃; the low-level heat source is the thermal circulation water in the device, 70t / h, 65℃, return The temperature is 33.4°C; the air temperature after water washing is 26.2°C, and the water content is 3.4vol%; low-grade heat is recovered at 2.12Gcal / h.

Embodiment 3

[0025] The air into the packed tower is 170t / h, 10℃, water content 0.82vol%; the supplementary water is steam condensed water in the device, 3.0t / h, 90℃; the low-level heat source is the secondary steam in the device, 4.0t / h, 109℃, 104kPa, return water temperature 80.8°C; air temperature after washing is 27.1°C, water content 3.5vol%; low-grade heat recovery 2.26Gcal / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com