Novel long-acting degradable biological nano membrane slowing releasing VEGF and bFGF and preparation method of nano membrane

A bio-nano-film and nano-fiber film technology, applied in the field of nano-biomedical materials, can solve the problems of poor controlled release time and controlled release concentration, achieve good biocompatibility, improve treatment effect, and reduce the risk of recurrence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

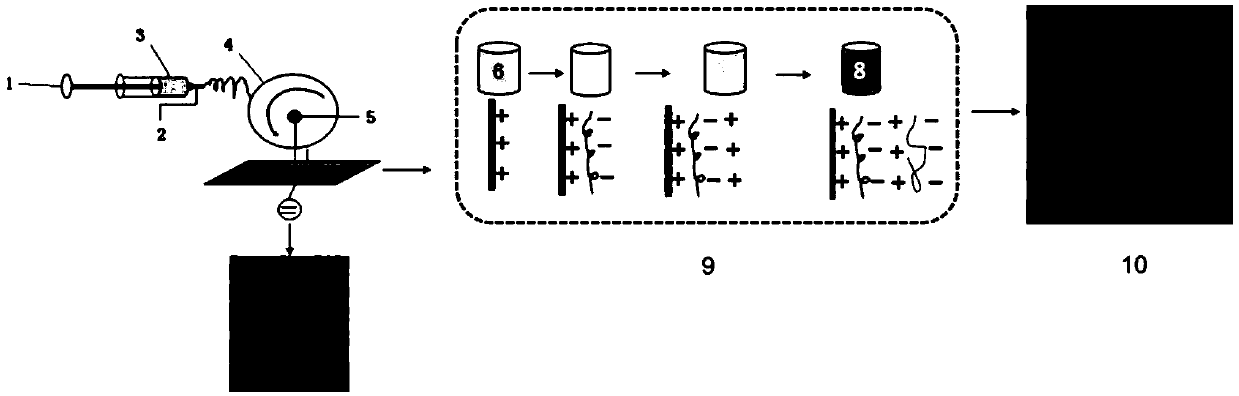

Embodiment 1

[0030] Polylactic acid was dissolved in chloroform / ethanol mixed solution to prepare a solution with a concentration of 10% (wt). Add this mixture solution to the electrospinning syringe controlled by the syringe pump, set the voltage of the high-voltage generator to 20KV, and the collection distance to 15cm, and a membrane composed of ultrafine fibers with a diameter of nanometer scale can be obtained, and then the The membrane was washed several times with deionized water and dried in vacuum before use. Step 1: Soak the dried membrane in polyethyleneimine (0.5-2mg / ml) solution for 30-60 minutes, and then soak it in deionized water for 10 minutes. Then VEGF and bFGF are made into a mixed growth factor solution with a concentration of 0.1-10 μg / ml, the membrane is soaked in the growth factor solution for 10-20 minutes for adsorption, and then washed with deionized water. Step 2: Then immerse in hyaluronic acid (0.5-2mg / ml) solution, growth factor solution and polyethyleneimin...

Embodiment 2

[0032] Polylactic acid was dissolved in chloroform / ethanol mixed solution to prepare a solution with a concentration of 8% (wt). Add this mixture solution to the electrospinning syringe controlled by the syringe pump, set the voltage of the high-voltage generator to 15KV, and the collection distance to 15cm, and a membrane composed of ultrafine fibers with a diameter of nanometer scale can be obtained, and then the The membrane was washed several times with deionized water and dried in vacuum before use. Step 1: Soak the dried membrane in polyethyleneimine (0.5-2mg / ml) solution for 30-60 minutes, and then soak it in deionized water for 10 minutes. Then VEGF and bFGF are made into a mixed growth factor solution with a concentration of 0.1-10 μg / ml, the membrane is soaked in the growth factor solution for 10-20 minutes for adsorption, and then washed with deionized water. Step 2: Then immerse in hyaluronic acid (0.5-2mg / ml) solution, growth factor solution and polyethyleneimine...

Embodiment 3

[0034] Polylactic acid was dissolved in a chloroform / ethanol mixed solution to prepare a solution with a concentration of 9% (wt). Add this mixture solution to the electrospinning syringe controlled by the syringe pump, set the voltage of the high-voltage generator to 20KV, and the collection distance to 15cm, and a membrane composed of ultrafine fibers with a diameter of nanometer scale can be obtained, and then the The membrane was washed several times with deionized water and dried in vacuum before use. Step 1: Soak the dried membrane in polyethyleneimine (0.5-2mg / ml) solution for 30-60 minutes, and then soak it in deionized water for 10 minutes. Then VEGF and bFGF are made into a mixed growth factor solution with a concentration of 0.1-10 μg / ml, the membrane is soaked in the growth factor solution for 10-20 minutes for adsorption, and then washed with deionized water. Step 2: Then immerse in hyaluronic acid (0.5-2mg / ml) solution, growth factor solution and polyethyleneimi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com