Functionalized gradient composite coating on surface of porous titanium alloy and preparation method thereof

A composite coating, titanium alloy technology, applied in the field of materials, can solve the problems of high temperature, detrimental material stability, difficult clinical application requirements of coating and specific bonding strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

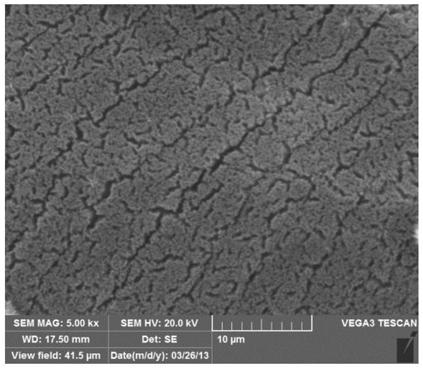

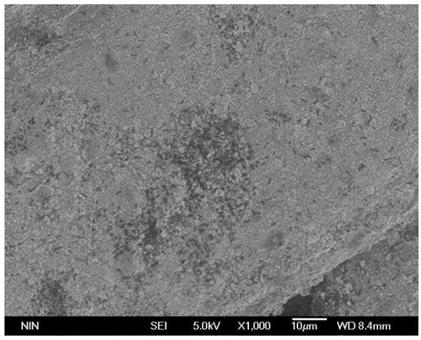

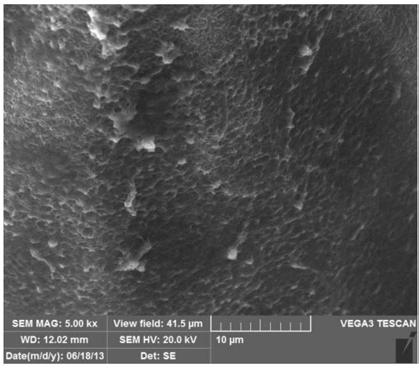

Image

Examples

Embodiment 1

[0028] A method for constructing a functional gradient composite coating on the surface of a porous titanium alloy, specifically comprising the steps of:

[0029] (1) Acid treatment: first prepare the corrosion solution required for acid treatment, select a mixed solution of alcohol nitric acid and hydrofluoric acid with a volume ratio of 1:3:7, and then immerse the porous titanium alloy in the corrosion solution for 3 minutes, then use After the tweezers are taken out, rinsed and dried with a hair dryer, observe whether the surface shows a bright silver-white metallic luster. If not, continue to soak in the corrosive solution until the surface shows a bright silver-white metallic luster, then stop.

[0030] (2) Alkaline heat treatment: ultrasonically clean the porous titanium alloy obtained in step (1) in acetone, alcohol, and deionized water for 20 minutes, then put it into NaOH aqueous solution (concentration: 5.0mol / L), heat it at 60°C for 24 hours, take it out and use Rin...

Embodiment 2

[0036] A method for constructing a functional gradient composite coating on the surface of a porous titanium alloy, specifically comprising the steps of:

[0037] (1) Acid treatment: first prepare the corrosion solution required for acid treatment, select a mixed solution of alcohol nitric acid and hydrofluoric acid with a volume ratio of 1:3:7, and then immerse the porous titanium alloy in the corrosion solution for 3 minutes, then use After the tweezers are taken out, rinsed and dried with a hair dryer, observe whether the surface shows a bright silver-white metallic luster. If not, continue to soak in the corrosive solution until the surface shows a bright silver-white metallic luster, then stop.

[0038] (2) Alkaline heat treatment: ultrasonically clean the porous titanium alloy obtained in step (1) in acetone, alcohol, and deionized water for 20 minutes, then put it into NaOH aqueous solution (concentration: 5.0mol / L), heat it at 60°C for 24 hours, take it out and use Rin...

Embodiment 3

[0044] A method for constructing a functional gradient composite coating on the surface of a porous titanium alloy, specifically comprising the steps of:

[0045] (1) Acid treatment: first prepare the corrosion solution required for acid treatment, select a mixed solution of alcohol nitric acid and hydrofluoric acid with a volume ratio of 1:3:7, and then immerse the porous titanium alloy in the corrosion solution for 3 minutes, then use After the tweezers are taken out, rinsed and dried with a hair dryer, observe whether the surface shows a bright silver-white metallic luster. If not, continue to soak in the corrosive solution until the surface shows a bright silver-white metallic luster, then stop.

[0046] (2) Alkaline heat treatment: ultrasonically clean the porous titanium alloy obtained in step (1) in acetone, alcohol, and deionized water for 20 minutes, then put it into NaOH aqueous solution (concentration: 5.0mol / L), heat it at 60°C for 24 hours, take it out and use Rin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com