Three-dimensional ordered macroporous-mesoporous titanium-silicon composite oxide carrier supported K-OMS-2 (Cryptomelane) catalyst and preparation method thereof

A K-OMS-2, composite oxide technology, used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the loss of active components, catalyst activity problems such as decrease in particle size, to achieve the effects of uniform particle size, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] According to a specific embodiment of the present invention, the three-dimensional ordered macroporous-mesoporous titanium-silicon composite oxide carrier is loaded with K-OMS-2 nanoparticle catalyst, and the method of the following steps is adopted:

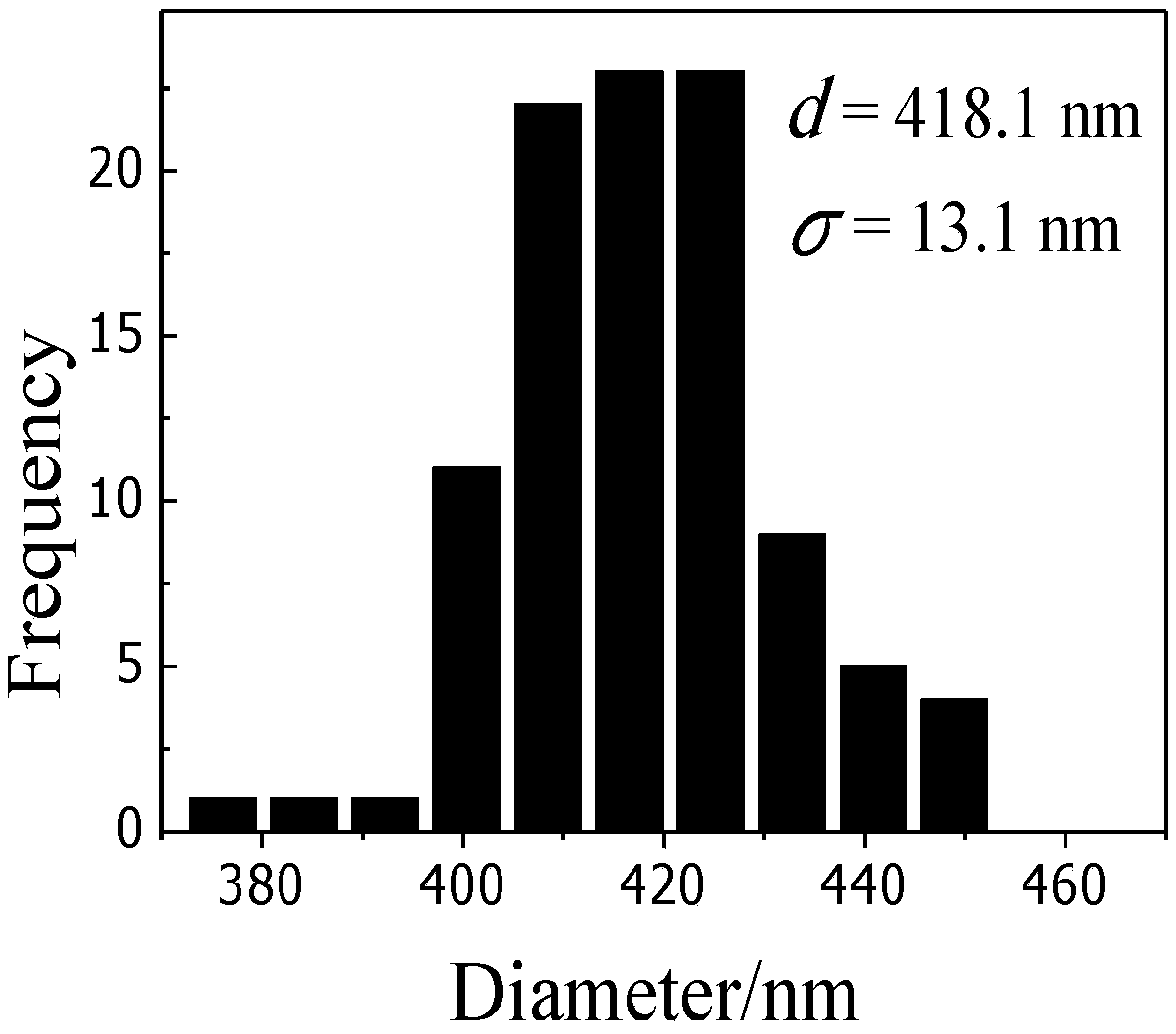

[0037] Preparation of Monodisperse Polymer Microspheres by Soap-free Emulsion Polymerization

[0038] Take 160-240mL of distilled water, add it to a round bottom flask, heat it in a water bath to 60-80°C, add 90-120mL of MMA, stir at an appropriate speed for 5-20min, then add 0.3-0.8 g weighed in advance Initiator K 2 S 2 o 8 (dissolve with 20-40mL water and heat to the same temperature). The reaction was continued for 1-5h under continuous stirring, and a milky white suspension was obtained. The particle size of the obtained microspheres is relatively uniform, and the use of the microspheres can make the finally obtained metal oxide have a better shape and structure. Such as figure 1 Shown, the particle diameter of...

Embodiment 2

[0040] Preparation of Colloidal Crystal Templates by Centrifugal Deposition

[0041] Place the microsphere emulsion in a centrifuge tube and centrifuge at 3000rpm for 10h to obtain a tightly packed colloidal crystal template, or place the microsphere emulsion in a flat-bottomed container and evaporate slowly in a drying oven at a temperature of 60°C. Deposition yields colloidal crystal templates. The scanning electron microscope images of the synthesized colloidal crystals are shown in image 3 As shown, the colloidal crystal template presents a hexagonal arrangement, forming a close-packed structure dominated by face-centered cubic (fcc).

Embodiment 3

[0043] 3DOM-mTi with different ratios of titanium to silicon x Si 1-x o 2 Preparation of composite oxide supports

[0044] By 3DOM-m Ti 0.9 Si 0.1 o 2 、3DOM-m Ti 0.7 Si 0.3 o 2 、3DOM-m Ti 0.5 Si 0.5 o 2 、3DOM-mTi 0.3 Si 0 . 7 o 2 、3DOM-m Ti 0.1 Si 0.9 o 2 The proportional relationship of the prepared 3DOM-m Ti was weighed respectively x Si 1-x o 2 12.24g, 9.52g, 6.8g, 4.08g, 1.36g of tetrabutyl titanate precursor materials were placed in 5 beakers, and then 0.832g, 2.496g, 4.16g, 5.824g, 7.488g tetraethyl orthosilicate, then add 5-10g ethanol and 3-8g P123 to 5 beakers, then put them on the stirrer and stir to form a clear solution, then slowly drop the above clear solution into 5 beakers respectively -10gHCl and 1-5mLH 2 O in five beakers. Finally, place the above mixed solution under magnetic stirring in a 30-60°C water bath and stir for 1-5 hours to obtain a uniform and transparent titanium-silicon precursor solution. After standing for 1-5 hours, use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com