Novel acidic zinc-plating additive

An acid galvanizing and additive technology, applied in the field of galvanizing surface treatment, can solve the problems of brittleness of the coating, poor ductility, no slowing effect of acid bath, narrow temperature range of brightener, etc., and achieve good ductility, convenient supplementary maintenance, The effect of excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

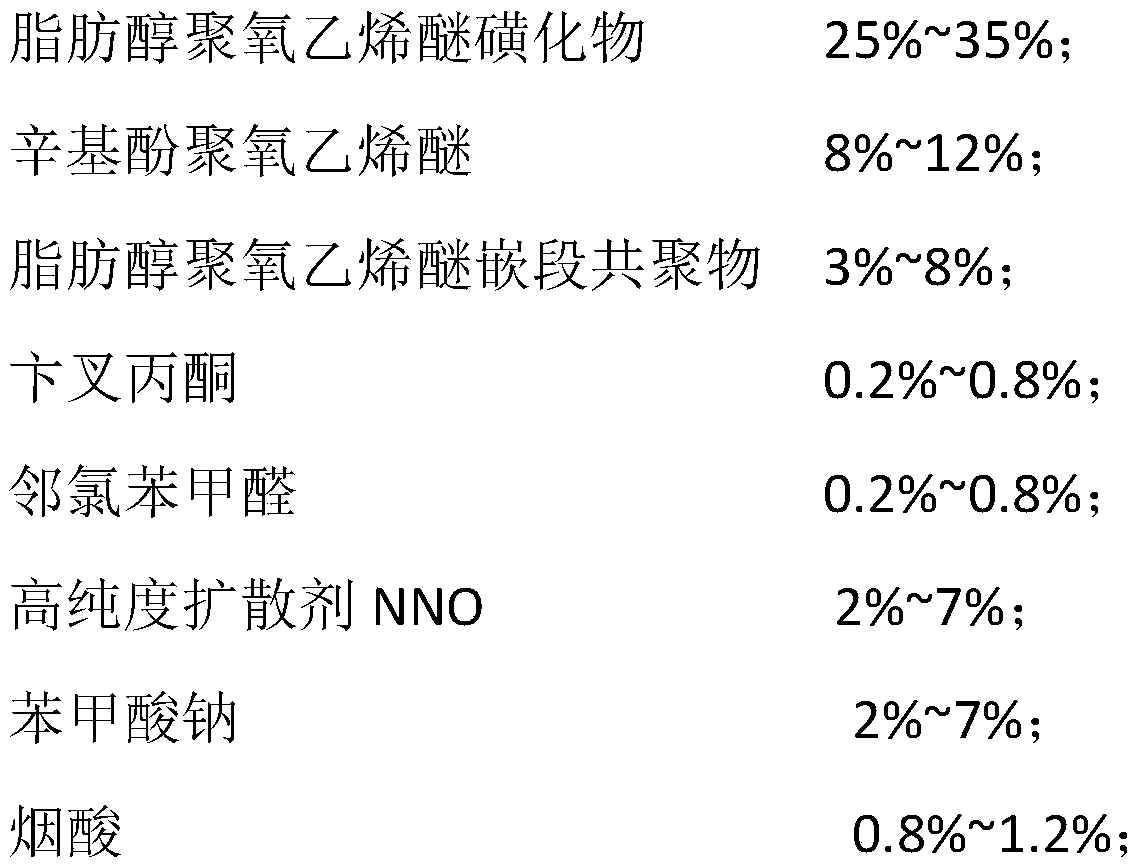

Embodiment 1

[0029] First configure 1L of additives, wherein the weight ratio of each component is 25% of fatty alcohol polyoxyethylene ether sulfonate; 8% of octylphenol polyoxyethylene ether; 3% of fatty alcohol polyoxyethylene ether block copolymer; Acetone 0.2%; o-chlorobenzaldehyde 0.2%; high-purity diffusion agent NNO 2%; sodium benzoate 2%; nicotinic acid 0.8%; cinnamic acid 0.8%; the balance is pure water. First add the calculated amount of pure water into the reaction kettle, then heat it up to 40 degrees, and then add fatty alcohol polyoxyethylene ether sulfonate, octylphenol polyoxyethylene ether, and fatty alcohol polyoxyethylene ether block in sequence while stirring. Copolymer, benzyl acetone, o-chlorobenzaldehyde, high-purity diffusing agent NNO, sodium benzoate, nicotinic acid, cinnamic acid, stir for 20 minutes until uniform without precipitation.

[0030] Configure 1L of plating solution so that the plating solution contains 45g of zinc chloride, 200g of potassium chlorid...

Embodiment 2

[0032] First configure 1L of additives, wherein the weight ratio of each component is 35% of fatty alcohol polyoxyethylene ether sulfonate; 12% of octylphenol polyoxyethylene ether; 8% of fatty alcohol polyoxyethylene ether block copolymer; Acetone 0.8%; o-chlorobenzaldehyde 0.8%; high-purity diffusing agent NNO 7%; sodium benzoate 7%; nicotinic acid 1.2%; cinnamic acid 1.2%; the balance is pure water. First add the calculated amount of pure water into the reaction kettle, then heat it up to 50 degrees, and then add fatty alcohol polyoxyethylene ether sulfonate, octylphenol polyoxyethylene ether, and fatty alcohol polyoxyethylene ether block in sequence while stirring Copolymer, benzyl acetone, o-chlorobenzaldehyde, high-purity diffusing agent NNO, sodium benzoate, nicotinic acid, cinnamic acid, stir for 20 minutes until uniform without precipitation.

[0033] Configure 1L of plating solution so that the plating solution contains 55g of zinc chloride, 240g of potassium chlorid...

Embodiment 3

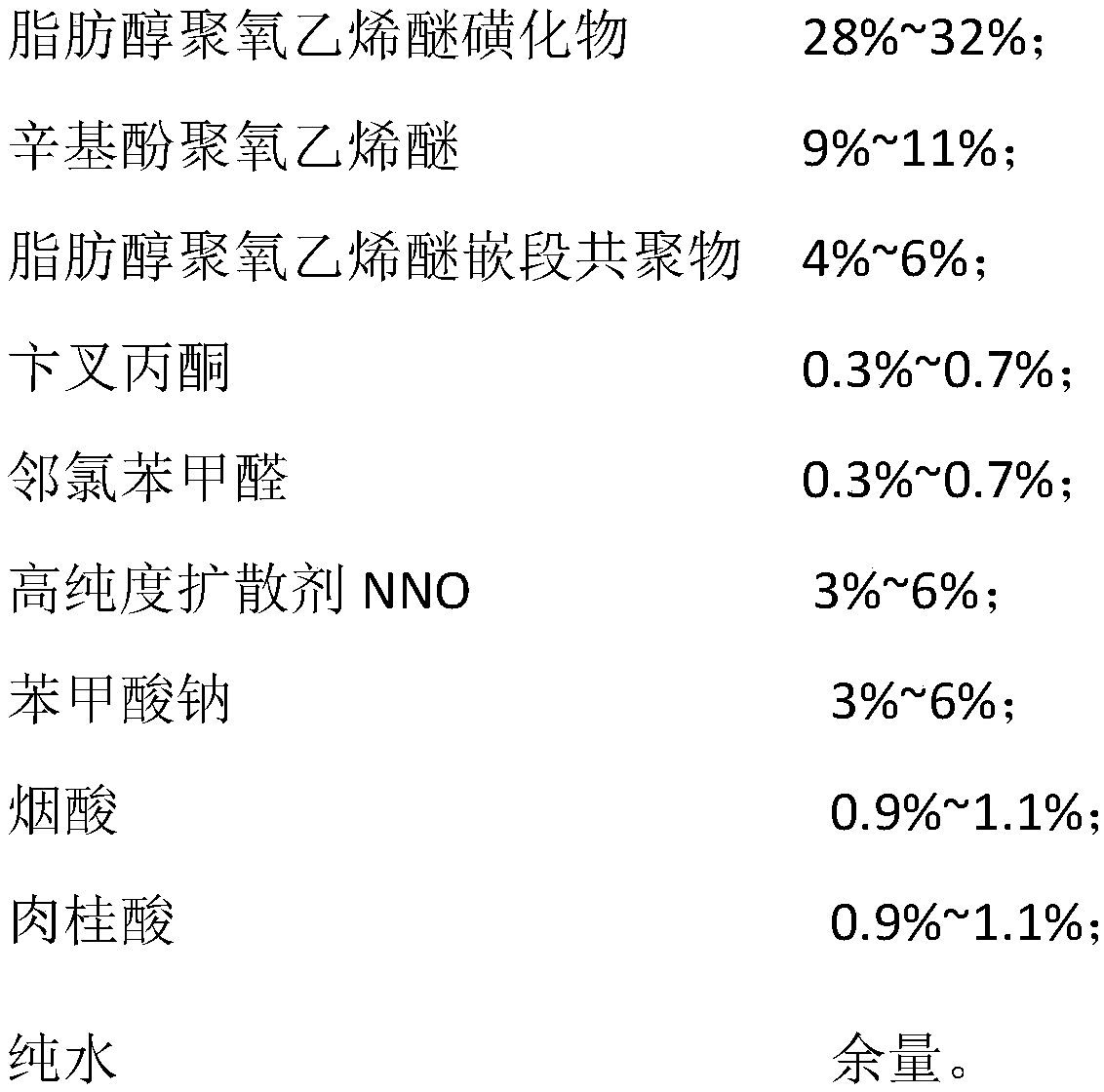

[0035] First configure 1L of additives, wherein the weight ratio of each component is 28% of fatty alcohol polyoxyethylene ether sulfonate; 9% of octylphenol polyoxyethylene ether; 4% of fatty alcohol polyoxyethylene ether block copolymer; Acetone 0.3%; o-chlorobenzaldehyde 0.3%; high-purity diffusing agent NNO 3%; sodium benzoate 3%; nicotinic acid 0.9%; cinnamic acid 0.9%; the balance is pure water. First add the calculated amount of pure water into the reactor, then heat it up to 43 degrees, then add fatty alcohol polyoxyethylene ether sulfonate, octylphenol polyoxyethylene ether, and fatty alcohol polyoxyethylene ether block in sequence while stirring Copolymer, benzyl acetone, o-chlorobenzaldehyde, high-purity diffusing agent NNO, sodium benzoate, nicotinic acid, cinnamic acid, stir for 20 minutes until uniform without precipitation.

[0036] Configure 1L of plating solution so that the plating solution contains 50g of zinc chloride, 220g of potassium chloride, 30g of bor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com