Film removing liquid and method for removing nitride film layer on surface of cobalt-based hard alloy

A technology of cobalt-based hard alloy and nitride film, which is applied in the field of metal surface treatment, can solve the problems of easy decomposition, difficult to accurately control the concentration, and danger in the storage and transportation process, and achieve the effect of effective removal and reduction of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

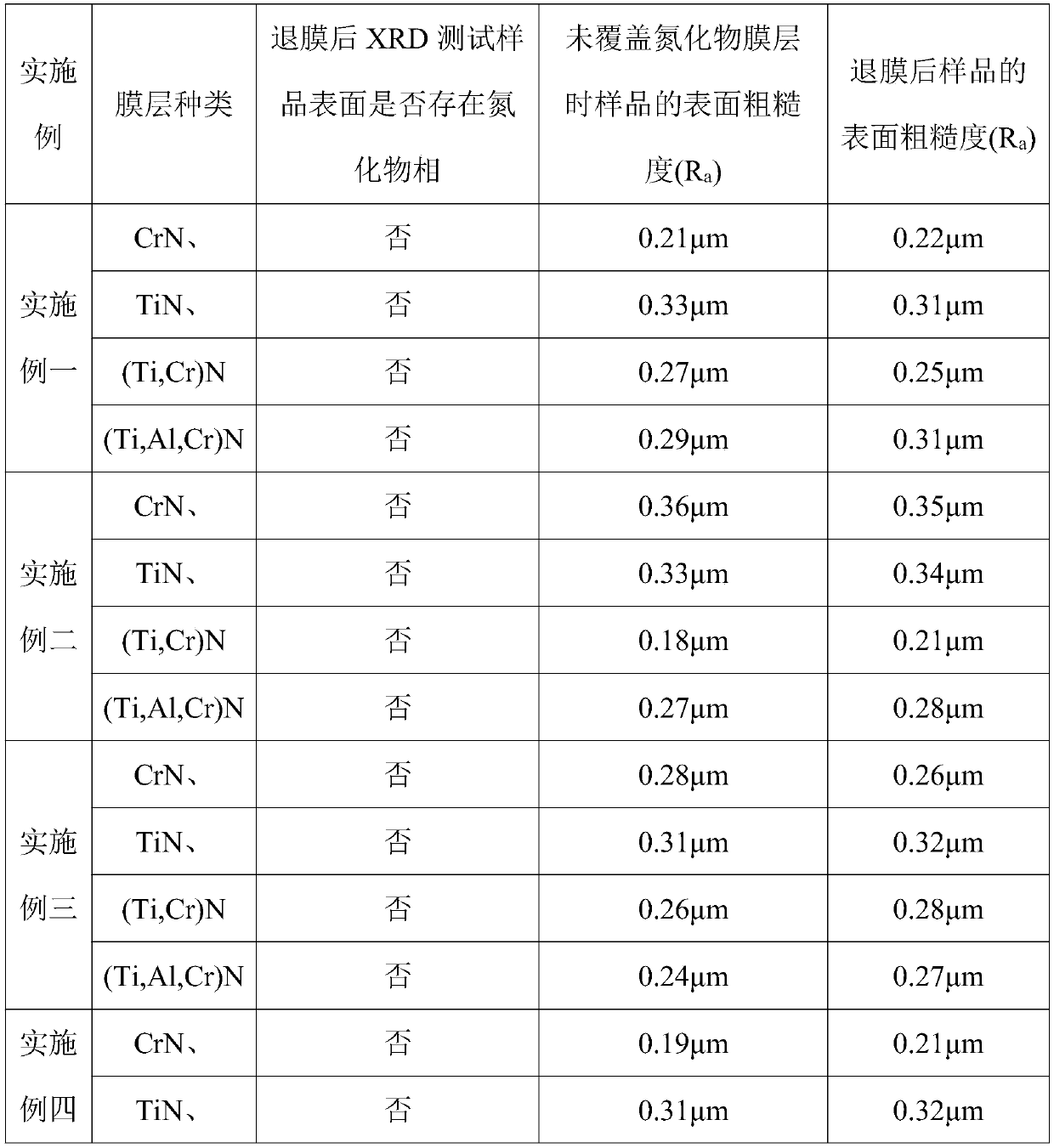

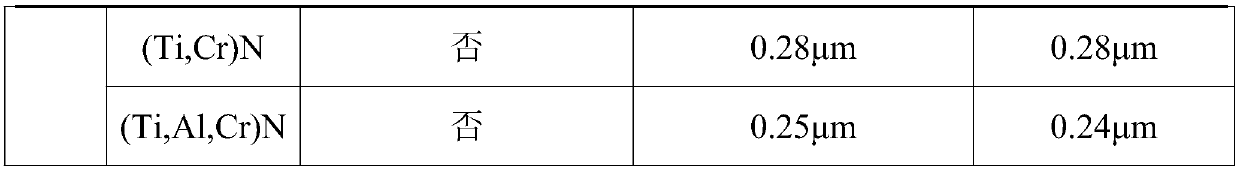

Examples

Embodiment 1

[0034] Prepare the film-removing solution, which consists of: 100 parts of sodium hydroxide, 1000 parts of sodium percarbonate, 10 parts of tetrasodium iminodisuccinate, 6 parts of sodium lignosulfonate, 0.015 parts of graphene oxide powder, iso 36 parts of propanol, 147 parts of ethanol, and 815 parts of deionized water. The stripping solution was prepared at a temperature of 15°C, and after the preparation was completed, it was stirred rapidly at a temperature of 15°C for 18 hours.

[0035] Put bucky paper in 1mol·L -1 The constant potential cathodic polarization treatment is carried out in the sodium hydroxide solution, the bucky paper is the cathode, the carbon rod is the anode, the distance between the cathode and the anode is 3cm, the voltage between the cathode and the anode is 1.8V, and the temperature is 25°C , and the treatment time was 20s. After cathodic polarization, the bucky paper was washed in deionized water and ethanol respectively, and dried in a vacuum ove...

Embodiment 2

[0041] Prepare the film-removing solution, which consists of 128 parts of sodium hydroxide, 1382 parts of sodium percarbonate, 16 parts of tetrasodium iminodisuccinate, 8 parts of sodium lignosulfonate, 0.015 parts of graphene oxide powder, iso 60 parts of propanol, 165 parts of ethanol, and 715 parts of deionized water. The stripping solution was prepared at a temperature of 15°C, and after the preparation was completed, it was stirred rapidly at a temperature of 15°C for 18 hours.

[0042] According to the method of Example 1, the bucky paper was subjected to constant potential cathodic polarization treatment, washed and dried.

[0043] According to the method of Example 1, the bucky paper after the constant potential cathodic polarization treatment was soaked in the film-removing solution.

[0044] According to the method of Example 1, the cobalt-based cemented carbide samples with CrN, TiN, (Ti, Cr)N and (Ti, Al, Cr)N film layers formed on the surface are contacted with t...

Embodiment 3

[0048] According to the method of Example 1, the membrane-removing solution was prepared.

[0049] Put bucky paper in 1mol·L -1 The constant potential cathodic polarization treatment was carried out in the sodium hydroxide solution, the bucky paper was the cathode, the carbon rod was the anode, the distance between the cathode and the anode was 2cm, the voltage between the cathode and the anode was 2V, and the temperature was 35°C. The treatment time is 15s. After the cathodic polarization is completed, the bucky paper is washed in deionized water and ethanol respectively, and then dried in a vacuum drying oven.

[0050] According to the method of Example 1, the bucky paper after the constant potential cathodic polarization treatment was soaked in the film-removing solution.

[0051] According to the method of Example 1, the cobalt-based cemented carbide samples with CrN, TiN, (Ti, Cr)N and (Ti, Al, Cr)N film layers formed on the surface are contacted with the ultrasonic vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com