Method for preparing cementitious materials with high mixing amounts of solid waste from quartzite slurry modified ardealite

A technology for cementing materials and phosphogypsum, which is applied in the field of preparing cementitious materials with high content of industrial solid waste, can solve problems such as adverse effects on the surrounding environment, and achieve the effects of improving comprehensive utilization rate, simple operation and shortening production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

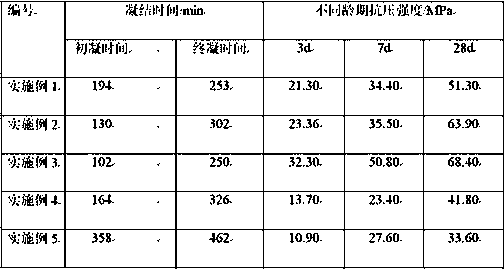

Embodiment 1

[0030] Mix the prepared phosphogypsum powder, mineral powder, fly ash and cement according to the total mass of 20%, 15%, 10% and 55% respectively, add water according to the mass ratio of water and ash of 0.385:1, and stir to make a thick slurry. Prepare matrix slurry A1; mix silica fume and artificial quartz mud at a mass ratio of 1:5 (dry basis) to prepare activator B1; mix A1 and B1 at a mass ratio of 19:1 (dry basis) and stir evenly , to obtain slurry C1; add polyaluminum sulfate according to 0.1% of the dry basis mass of slurry C1, add polycarboxylate superplasticizer mother liquor according to 0.1% of the dry basis mass of slurry C1, and stir evenly to obtain good fluidity The cementitious material P1. Relevant properties are determined according to "GB / T1346-2011 Cement Standard Consistency Water Consumption, Setting Time, and Stability Test Method" to determine the setting time, and according to "GB / T17671-1999 Cement Mortar Strength Test Method (ISO Method)" to measu...

Embodiment 2

[0032] Mix the prepared phosphogypsum powder, mineral powder, and cement according to the total mass of 25%, 25%, and 50% respectively, add water according to the water-to-ash mass ratio of 0.394:1, stir to make a thick slurry, and prepare the matrix slurry A2; Silica fume and artificial quartz mud are mixed uniformly by mass 2:5 (dry basis) to prepare activator B2; A2 and B2 are mixed and stirred evenly by mass 12:1 (dry basis) to prepare slurry C2; Add polyaluminum chloride at 0.2% of the dry basis mass of slurry C2, add polycarboxylate superplasticizer mother liquor at 0.3% of the dry basis mass of slurry C2, and stir evenly to obtain gelling material P2 with better fluidity. Relevant performance inspection method is with embodiment 1.

Embodiment 3

[0034]Mix the prepared phosphogypsum powder, fly ash and cement according to the total mass of 25%, 25% and 55% respectively, add water according to the mass ratio of water and ash of 0.376:1, stir to make a thick slurry, and prepare the matrix slurry A3; Mix silica fume and artificial quartz stone mud at a mass ratio of 2:5 (dry basis) to prepare activator B3; mix and stir A3 and B3 at a mass ratio of 12:1 (dry basis) to prepare slurry C3 Add polyaluminum chloride according to 0.1% of the dry basis mass of the slurry C3, add polycarboxylate superplasticizer mother liquor according to 0.5% of the dry basis mass of the slurry C3, and stir evenly to obtain the gelling material P3 with better fluidity . Relevant performance inspection method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com