Preparation method of lithium ion battery negative electrode material silicon oxide-carbon/graphite

A lithium ion battery, silicon oxide technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., to improve electrochemical performance, enhance electronic conductivity, and facilitate industrial mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

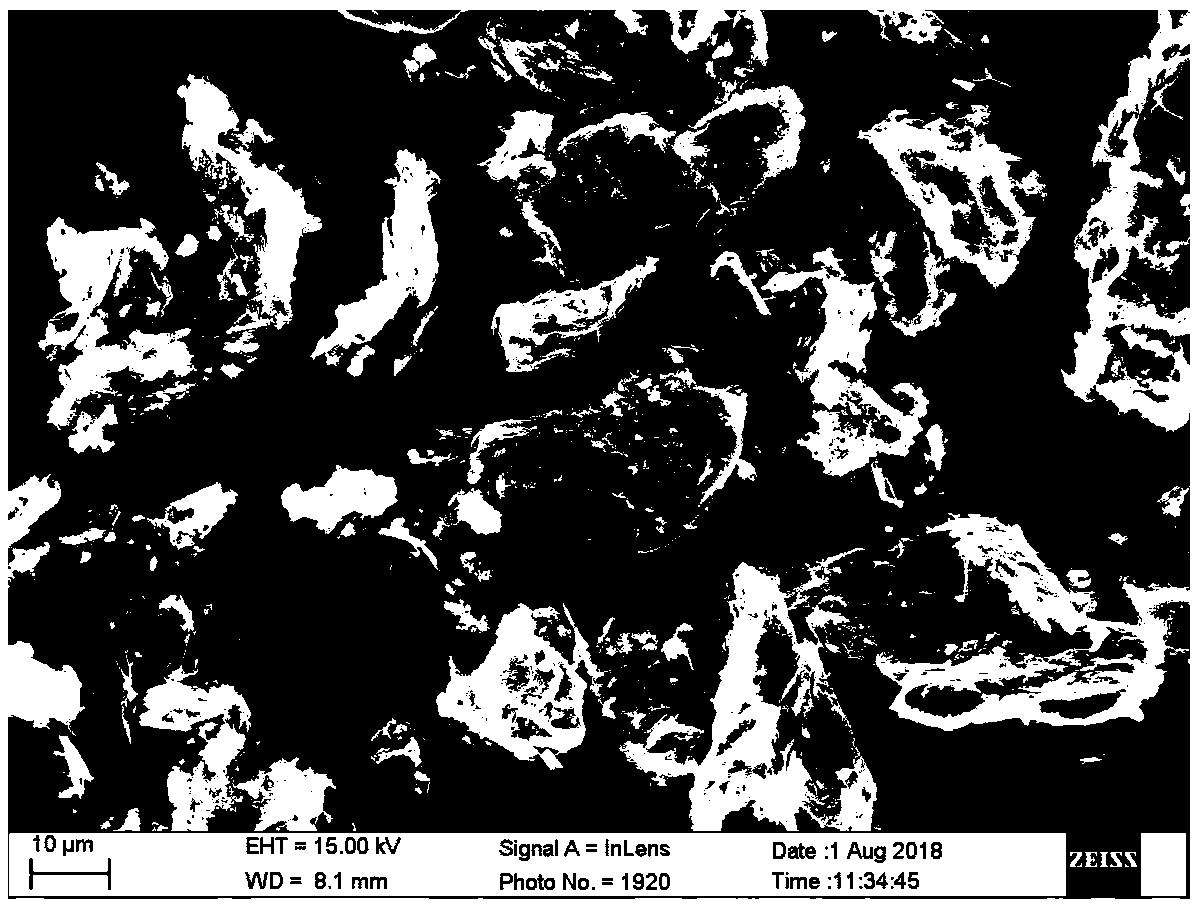

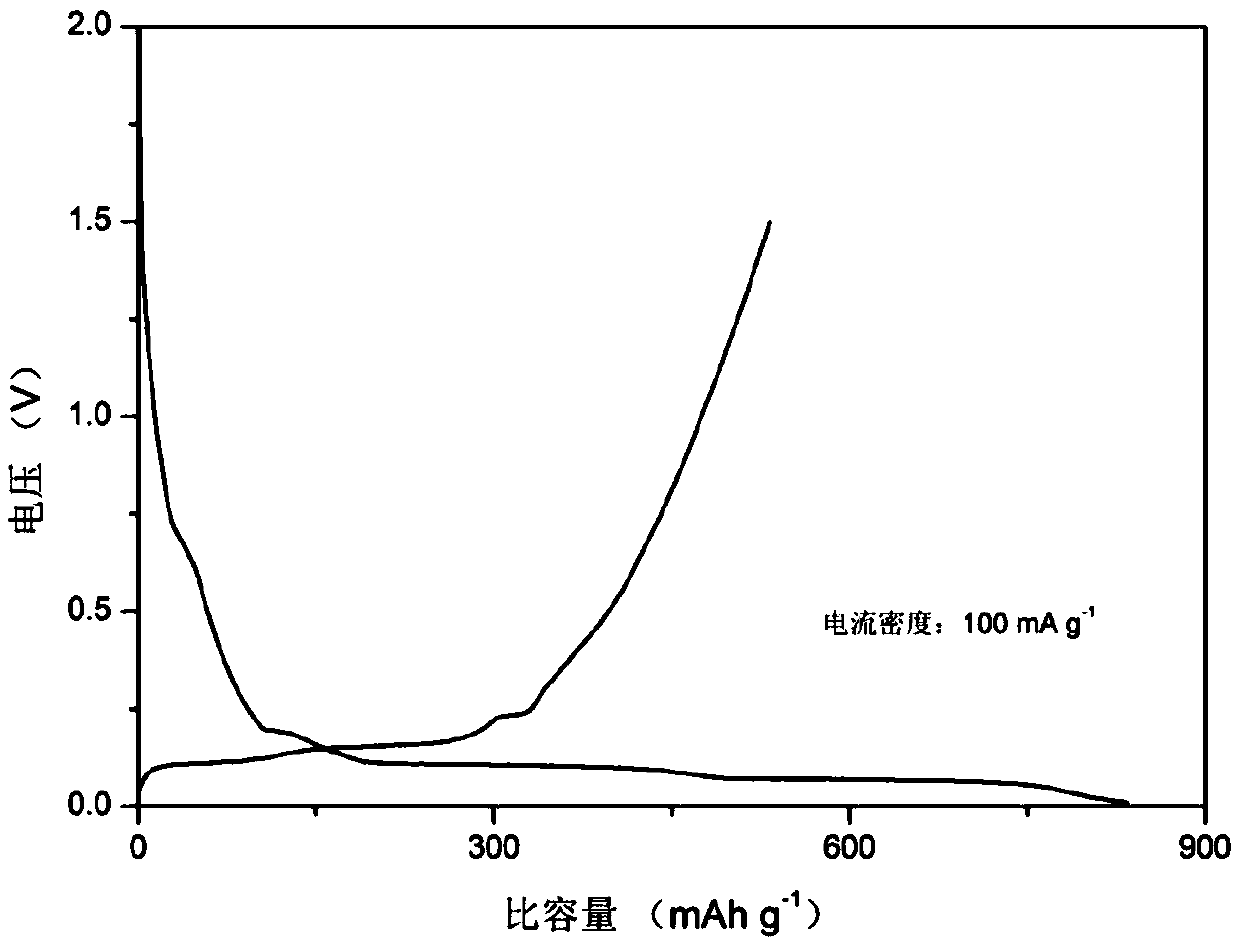

Image

Examples

Embodiment 1

[0030] Weigh 2.08g of tetraethyl orthosilicate and dissolve it in 4mL of ethanol, stir for a while, then add 2mL of deionized water and 1mL of hydrochloric acid into it to obtain a mixed solution A. After the mixture A was vigorously stirred for 1 hour, a silica sol was obtained, and the pH of the sol was adjusted to 6.5 with 1M ammonia water, and the stirring was continued for a period of time to obtain a silica gel.

[0031] Weigh 1.98g of graphite powder and disperse it in 70mL of deionized water. After ultrasonically stirring for a period of time, weigh 0.6g of sucrose, add it to the graphite powder dispersion, and stir until completely dissolved to obtain a mixed solution B.

[0032] Add the mixed solution B into the silicone gel, and after stirring for a period of time, a silicon-oxygen-sucrose-graphite black gel is obtained. The black gel was transferred to a ball mill jar, the ball milling speed was 300 rpm, and the ball milling time was 3 hours. The ball milled black ...

Embodiment 2

[0038] Weigh 4.16g of tetraethyl orthosilicate and dissolve it in 8mL of ethanol, stir for a while, then add 13mL of deionized water and 2mL of hydrochloric acid into it to obtain a mixed solution A. After the mixture A was vigorously stirred for 1 hour, a silica sol was obtained, and the pH of the sol was adjusted to 6.5 with 1M ammonia water, and the stirring was continued for a period of time to obtain a silica gel.

[0039] Weigh 2.08g of graphite powder and disperse it in 70mL of deionized water. After ultrasonically stirring for a period of time, weigh 2g of sucrose, add it to the graphite powder dispersion, and stir until completely dissolved to obtain a mixed solution B.

[0040] Add the mixed solution B into the silicone gel, and after stirring for a period of time, a silicon-oxygen-sucrose-graphite black gel is obtained. The black gel was transferred to a ball mill jar, the ball milling speed was 400 rpm, and the ball milling time was 1 hour. The ball milled black ge...

Embodiment 3

[0045] Weigh 4.16g of tetraethyl orthosilicate and dissolve it in 5mL of ethanol, stir for a while, then weigh 5mL of deionized water and 2mL of hydrochloric acid and add it to obtain a mixed solution A. After the mixture A was vigorously stirred for 1 hour, a silica sol was obtained, and the pH of the sol was adjusted to 6.5 with 1M ammonia water, and the stirring was continued for a period of time to obtain a silica gel.

[0046] Weigh 6g of graphite powder and disperse it in 80mL of deionized water. After ultrasonically stirring for a period of time, weigh 1.2g of sucrose, add it to the graphite powder dispersion, and stir until completely dissolved to obtain a mixed solution B.

[0047] Add the mixed solution B into the silicone gel, and after stirring for a period of time, a silicon-oxygen-sucrose-graphite black gel is obtained. The black gel was transferred to a ball mill jar, the ball milling speed was 200 rpm, and the ball milling time was 5 hours. The ball milled blac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com