A preparing method and application of a three-dimensional nanoflower metal-organic framework material

A metal-organic framework, three-dimensional nanotechnology, which is applied in the field of nanomaterial preparation technology and energy storage, can solve the problems that have not yet been developed, and achieve the effects of good supercapacitive performance, favorable ion transport, excellent specific capacitance and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

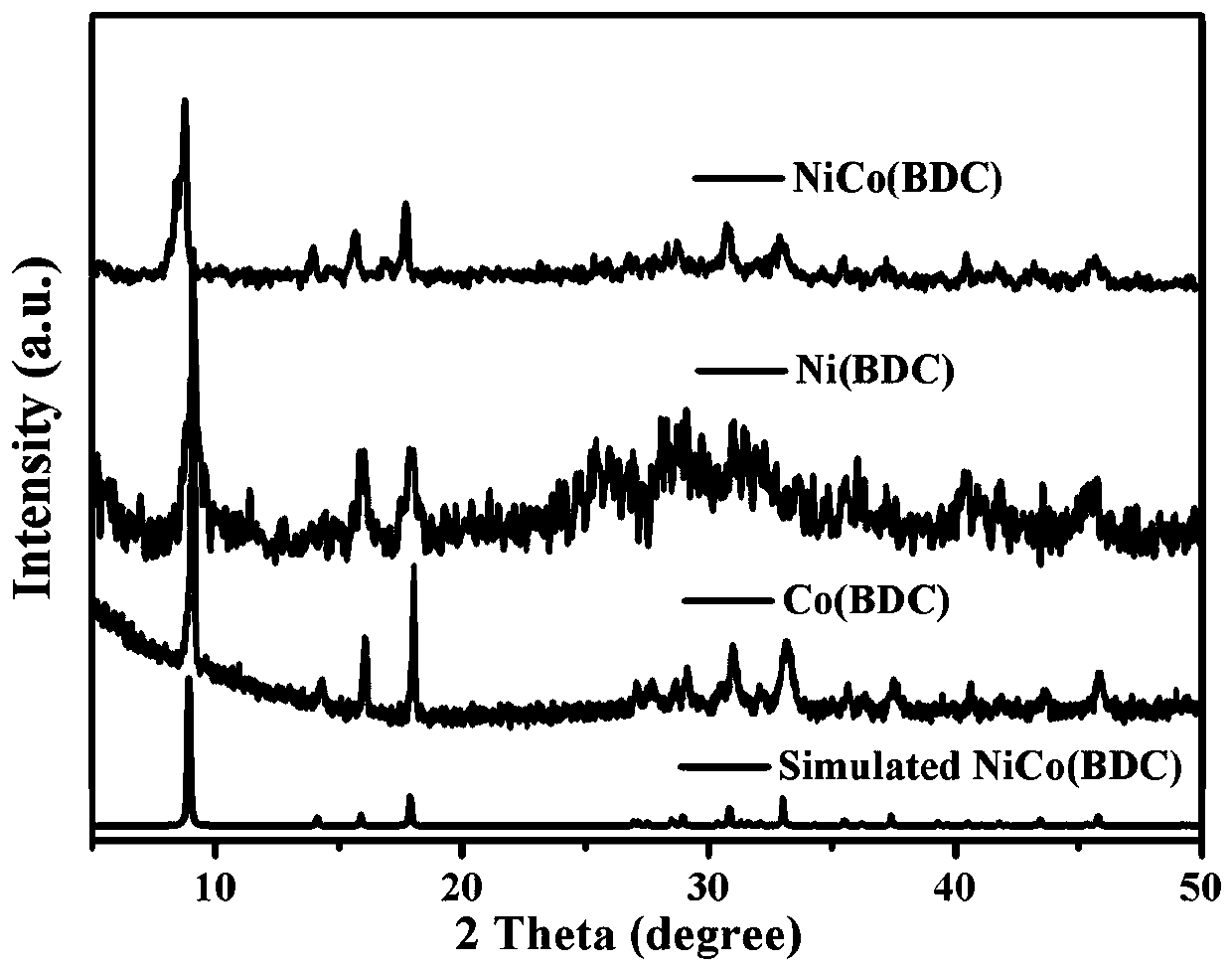

[0034] Embodiment 1 (preparation of NiCo-MOFs)

[0035] Dissolve 0.0892g of cobalt chloride hexahydrate, 0.0891g of nickel chloride hexahydrate, and 0.1246g of terephthalic acid in a mixture made of 32mL N,N-dimethylformamide, 2mL ethanol, and 2mL deionized water. In the solution, sonicate at room temperature for 20 minutes to mix the reactants uniformly to obtain the mixed solution A.

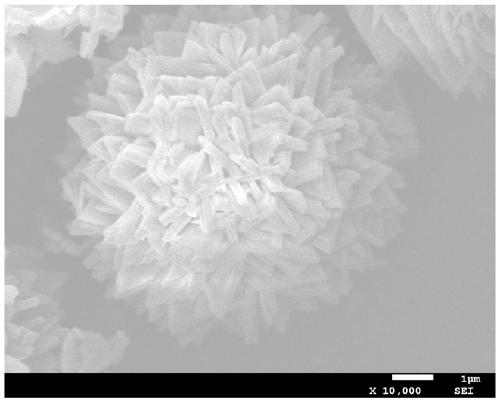

[0036] Transfer the mixed solution A to a 50 mL polytetrafluoroethylene liner, put it into a stainless steel container and keep it warm at 140°C for 48 hours, then cool it down to room temperature for 8 hours, and finally obtain a yellow-white solid powder crystal. Centrifuge and wash three times with N, N-dimethylformamide and water respectively, the rotation speed is 8000rpm / min, and the centrifugation time is 6min / time, and the obtained product is vacuum-dried at 80°C for 12-16 hours to obtain petals composed of two-dimensional nanosheets with a thickness of about 110-140nm three-dimension...

Embodiment 2

[0037] Embodiment 2 (preparation of NiMn-MOFs)

[0038] Take 0.0742g of manganese chloride hexahydrate, 0.0891g of nickel chloride hexahydrate, and 0.1246g of terephthalic acid dissolved in a mixture made of 32mLN,N-dimethylformamide, 2mL ethanol, and 2mL deionized water. In the solution, sonicate at room temperature for 20 minutes to mix the reactants uniformly to obtain the mixed solution B.

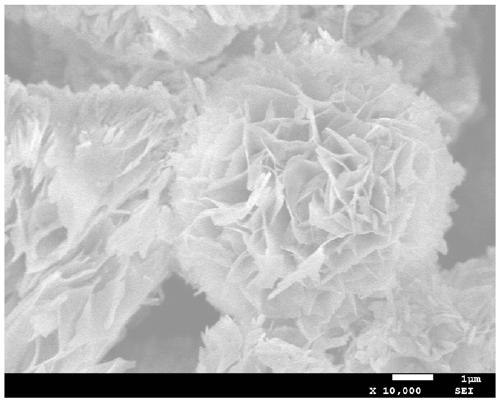

[0039] The mixed liquid B was transferred to a 50mL polytetrafluoroethylene liner, and then put into a stainless steel container at a temperature of 140°C for 48 hours, cooled to room temperature for 8 hours, and finally a light green solid powder crystal was obtained. Centrifuge and wash three times with N, N-dimethylformamide and water respectively, the rotation speed is 8000rpm / min, and the centrifugation time is 6min / time, and the obtained product is vacuum-dried at 80°C for 12-16 hours to obtain petals composed of two-dimensional nanosheets with a thickness of 30-60nm spherical t...

Embodiment 3

[0040] Example 3 (Preparation of NiMn-MOFs (nickel chloride hexahydrate: manganese chloride hexahydrate molar mass ratio is 1:0.8))

[0041]Take 0.0660g of manganese chloride hexahydrate, 0.0990g of nickel chloride hexahydrate, and 0.1246g of terephthalic acid and dissolve them in a mixture made of 32mL N,N-dimethylformamide, 2mL ethanol, and 2mL deionized water. In the solution, sonicate at room temperature for 20 min to mix the reactants uniformly to obtain a mixed solution C.

[0042] Transfer the mixed liquid C to a 50mL polytetrafluoroethylene liner, put it into a stainless steel container and keep it warm at 140°C for 48 hours, then cool it down to room temperature for 8 hours, and finally obtain light green solid powder crystals. Centrifuge and wash three times with N, N-dimethylformamide and water respectively, the rotation speed is 8000rpm / min, and the centrifugation time is 6min / time, and the obtained product is vacuum-dried at 80°C for 12-16 hours to obtain two-dime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com