A kind of preparation method for the oligomer that is used to improve the anti-wet performance of rubber

An anti-wet-slip, oligomer technology, applied in the field of oligomer preparation, can solve the problems of complex steps, unsuitable for industrial production, and high molecular weight of poly-α-methylstyrene resin, so as to improve reaction and production efficiency, The effect of reducing cost and environmental pressure, improving wet skid performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

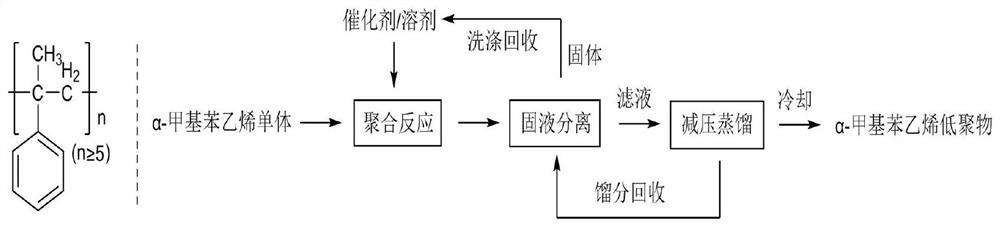

Method used

Image

Examples

Embodiment 1

[0059] (1) Weigh 1.2g of concentrated sulfuric acid, 5g of clay and 50g of xylene, and add them into a 500ml three-necked flask.

[0060] (2) Place the three-neck flask in ice-salt water to keep warm, and at the same time turn on the stirrer, and proceed to the next step when the temperature is stabilized at 0°C.

[0061] (3) Weigh 100 g of α-methylstyrene monomer, add it into a 250 ml constant pressure dropping funnel, open the lower stopcock, and slowly drop the monomer into the three-necked flask. Pay attention to monitoring the temperature. If the temperature rises too fast, the dropping rate can be appropriately reduced to keep the temperature moderately at 0-3°C.

[0062] (4) Start timing after the dropwise addition, and keep reacting at this temperature for 1 h.

[0063] (5) After the reaction is over, pour the solution in the three-necked flask into a 500ml beaker, add 100g of xylene or distilled under reduced pressure to dilute, stir well and then filter it with a Bu...

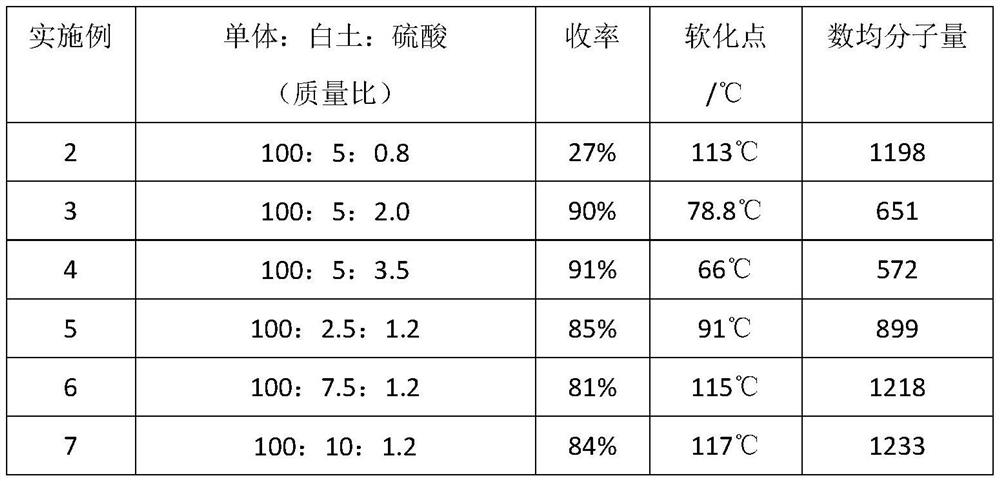

Embodiment 2-7

[0067] (1) Weigh different ratios of α-methylstyrene monomer, activated clay, sulfuric acid and 50 g of xylene, and add the activated clay, sulfuric acid and 50 g of xylene into a 500 ml three-neck flask.

[0068] (2) Place the three-neck flask in ice-salt water to keep warm, and at the same time turn on the stirrer, and proceed to the next step when the temperature is stabilized at 0°C.

[0069] (3) Add α-methylstyrene monomer into a 250ml constant-pressure dropping funnel, open the lower stopcock, and slowly drop the monomer into the three-necked flask. Pay attention to monitoring the temperature. If the temperature rises too fast, the dropping rate can be appropriately reduced to keep the temperature moderately at 0-3°C.

[0070] (4) Start timing after the dropwise addition, and keep reacting at this temperature for 1 h.

[0071] (5) After the reaction is over, pour the solution in the three-necked flask into a 500ml beaker, add 100g of xylene or distilled under reduced pr...

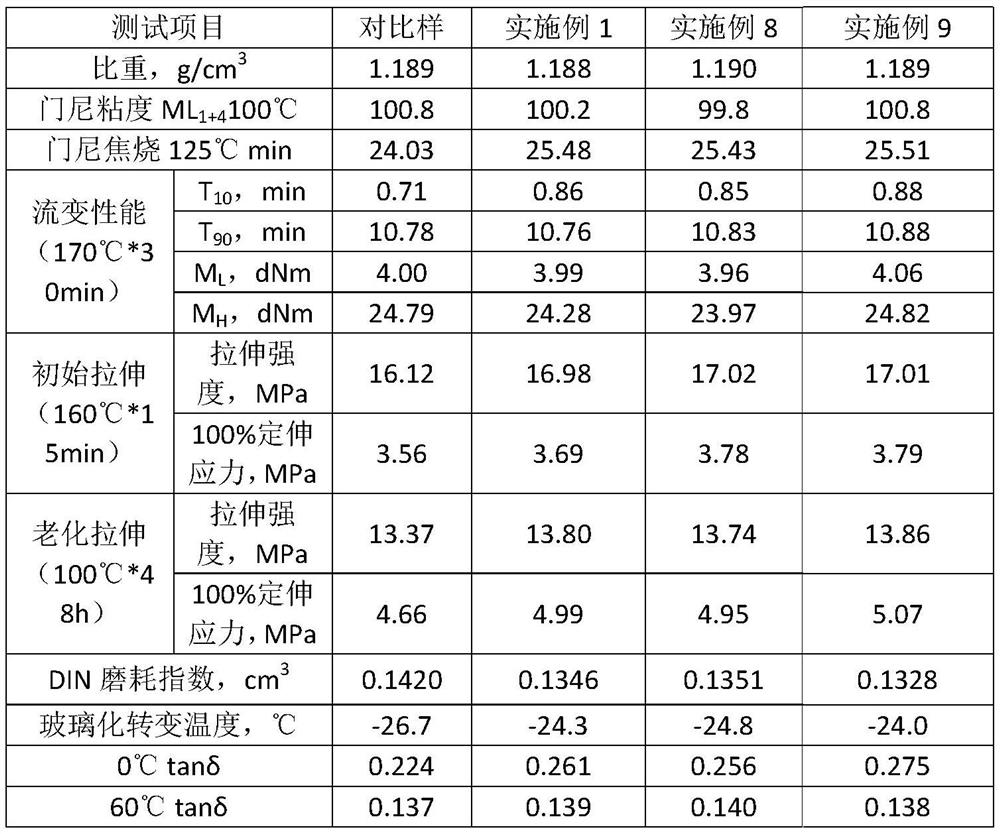

Embodiment 8

[0091] (1) Weigh 1.2 g of concentrated sulfuric acid and 1 g of acetonitrile, and mix them uniformly in an ice-water bath for later use.

[0092] (2) Weigh 100g of α-methylstyrene monomer, 5g of clay and 30g of xylene, and add them to a 500ml three-necked flask

[0093] (3) Place the three-neck flask in ice-salt water to keep warm, and at the same time turn on the stirrer, and proceed to the next step when the temperature is stabilized at 0°C.

[0094] (4) Add the sulfuric acid / acetonitrile solution prepared in step (1) into a 100ml constant-pressure dropping funnel, open the lower stopcock, and slowly drop the mixed solution into the three-necked flask. Pay attention to monitoring the temperature. If the temperature rises too fast, reduce the titration rate in time to keep the temperature moderately at 0-3°C.

[0095] (5) Start timing after the dropwise addition, and keep reacting at this temperature for 2 hours.

[0096](6) After the reaction is over, pour the solution in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com