Nano-modified lithium ion battery membrane, manufacturing method thereof and product containing same

A lithium-ion battery and nano-modification technology, which is applied in the preparation of lithium-ion battery diaphragms and the preparation of nano-modified lithium-ion battery diaphragms, can solve problems affecting the use of diaphragms and poor wettability, and achieve increased liquid absorption efficiency and reduced Small charge transfer resistance, the effect of not increasing the original size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

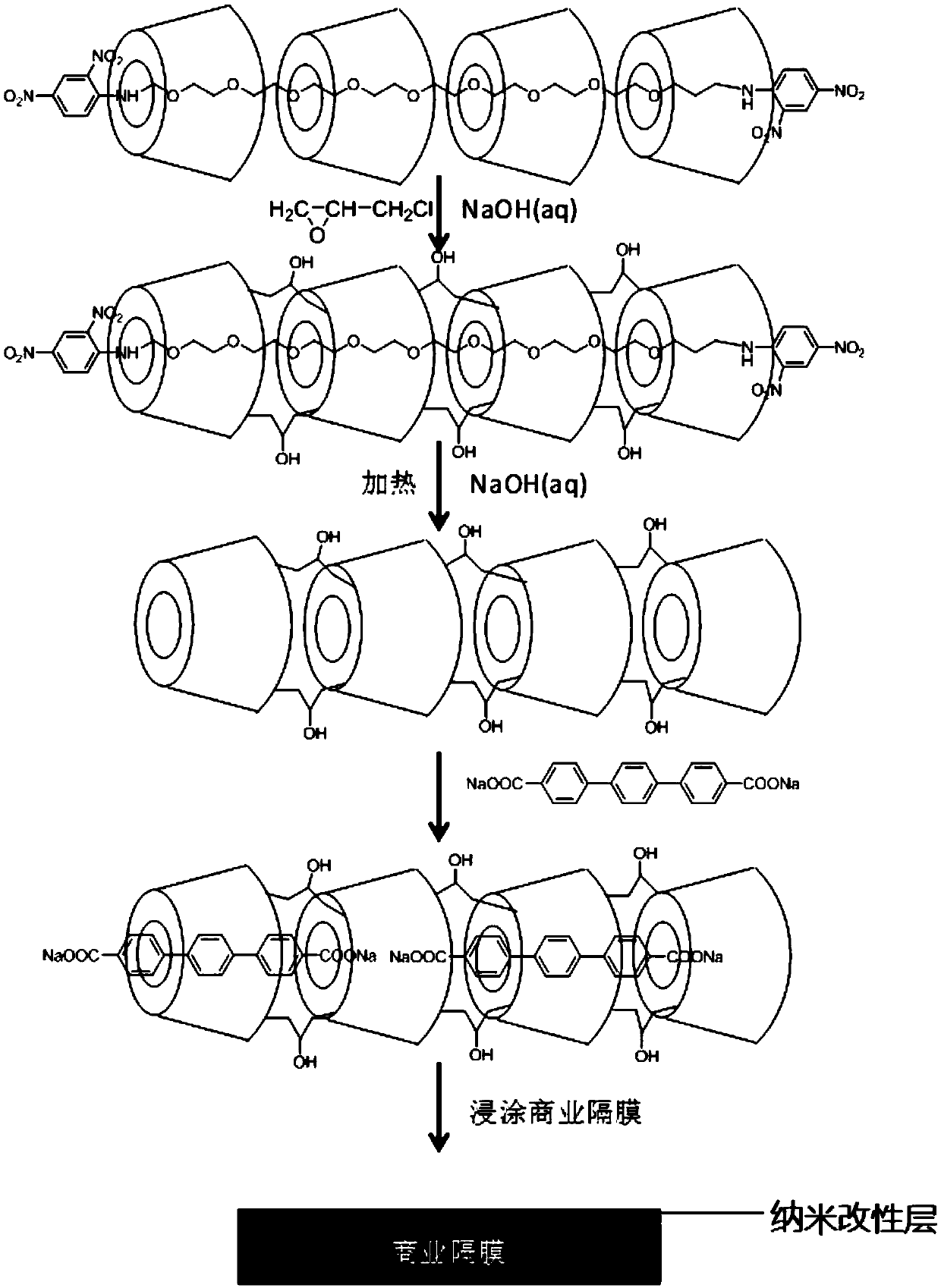

[0059] This embodiment provides a preparation method of a nano-modified lithium-ion battery separator, such as figure 1 shown, including the following steps:

[0060] Preparation of cyclodextrin polyrotaxane inclusion compound: at room temperature, add 10 mL of 100 mg / mL polyethylene glycol diamine (molecular weight: 1000) aqueous solution into saturated cyclodextrin aqueous solution, stir well and then let it stand 10min; filter and dry the obtained precipitate, then dissolve it in dimethylacetamide and add 1g of 2,4-dinitrofluorobenzene for stirring to prevent the decomposition of cyclodextrin polyrotaxane inclusion complex; Add 1mL of ether to terminate the reaction and obtain a precipitate; wash the precipitate with ether to remove unreacted 2,4-dinitrofluorobenzene, and use dimethylacetamide to remove unreacted cyclodextrin, poly Derivatives of ethylene glycol diamine and dinitrobenzene;

[0061] Preparation of cyclodextrin molecular tube inclusion compound: Take 1 g of...

Embodiment 2

[0065] This embodiment provides a preparation method of a nano-modified lithium-ion battery diaphragm, comprising the following steps:

[0066] Preparation of cyclodextrin polyrotaxane clathrate: at room temperature, add 15 mL of 70 mg / mL polyethylene glycol diamine (molecular weight: 3350) aqueous solution into saturated cyclodextrin aqueous solution, stir well and let stand 5min; the obtained precipitate was filtered and dried, then dissolved in 50mL aqueous solution with a concentration of 2mg / mL dimethylacetamide and stirred by adding 1g of 2,4-dinitrofluorobenzene to prevent cyclodextrin aggregation Decomposition of rotaxane clathrates; add 1 mL of ether to terminate the reaction and obtain a precipitate; wash the precipitate with ether to remove unreacted 2,4-dinitrofluorobenzene, and use dimethylacetamide to remove Derivatives of cyclodextrin, polyethylene glycol diamine and dinitrobenzene that have not participated in the reaction;

[0067] Preparation of cyclodextrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com