Manufacturing method of magnetic radom access memory unit array and peripheral circuit connecting wires

A random access memory and cell array technology, applied in the manufacture/processing of electromagnetic devices, circuits, and parts of electromagnetic equipment, etc., can solve problems such as copper surface roughness, MRAM device pollution, damage diffusion barrier, etc., and achieve electrical performance optimization. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

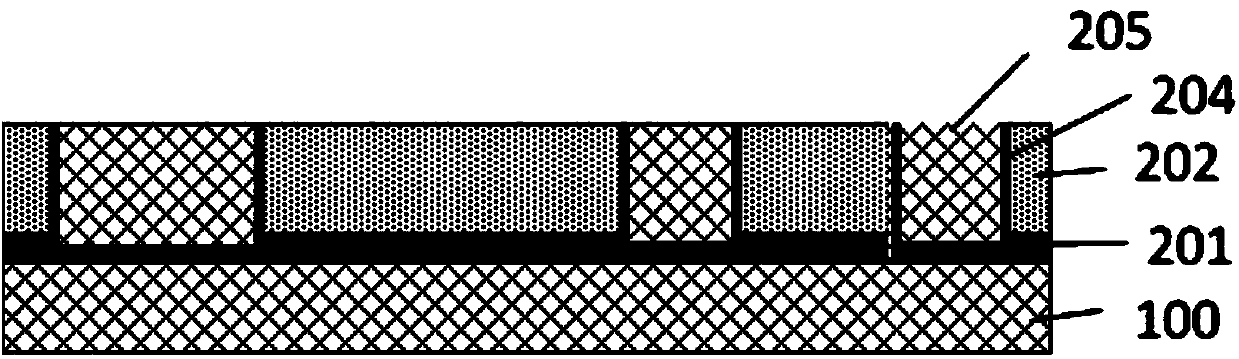

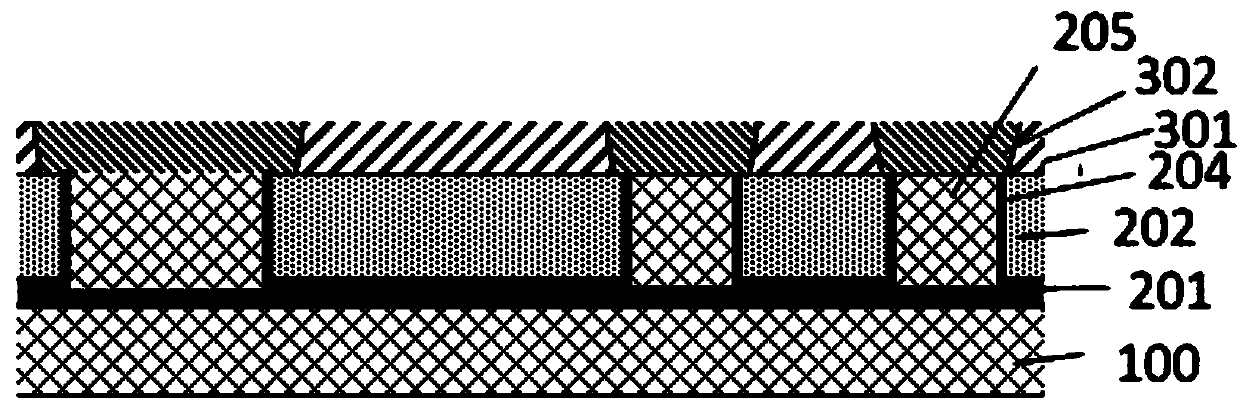

[0028] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that all the drawings of the present invention are in simplified form and use inaccurate scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0029] The invention relates to a manufacturing method of a magnetic random access memory unit array and peripheral circuit wiring, which adopts the through hole V in the copper metal x (x>=1) make a bottom electrode contact (BEC) layer to make the copper via V x cover. Wherein, the bottom electrode contact material is Ta, TaN, Ti, TiN, W or WN, etc., including but not limited to the preparation of magnetic random access memory (MRAM), and is not limited to any process sequence or flow, as long as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com