Non-polar patterned AlN/sapphire composite substrate and manufacturing method thereof

A technology for patterning sapphire and composite substrates, which is used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve large lattice mismatch and thermal mismatch, and is difficult to grow low dislocation density Group III nitrides Semiconductor materials and other issues, to achieve the effect of suppressing anisotropy, reducing stacking faults, edge and screw dislocation densities, and improving crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

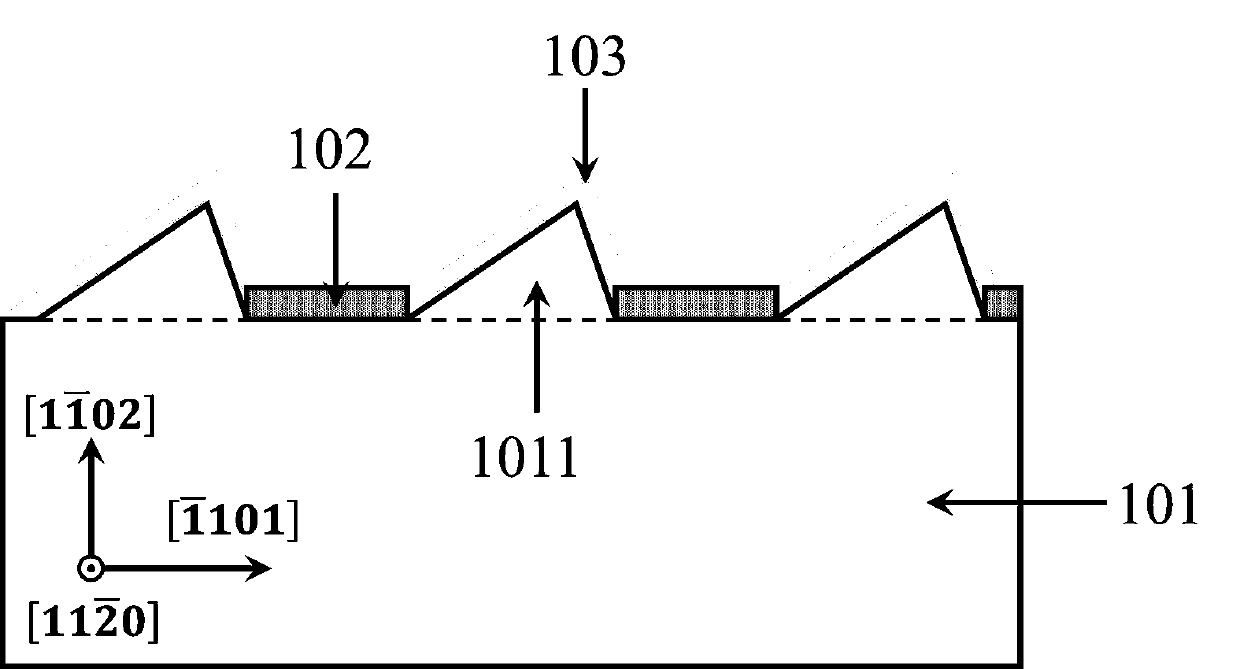

[0030] Such as figure 1 As shown, it is a schematic structural diagram of a non-polar patterned AlN / sapphire composite substrate provided by the present invention, and its structure includes an r-plane patterned sapphire substrate (101), a sapphire pattern (1011), and a mask layer (102) and AlN capping layer (103). Wherein the r-plane sapphire pattern (1011) is actually a part of the patterned r-plane sapphire substrate (101).

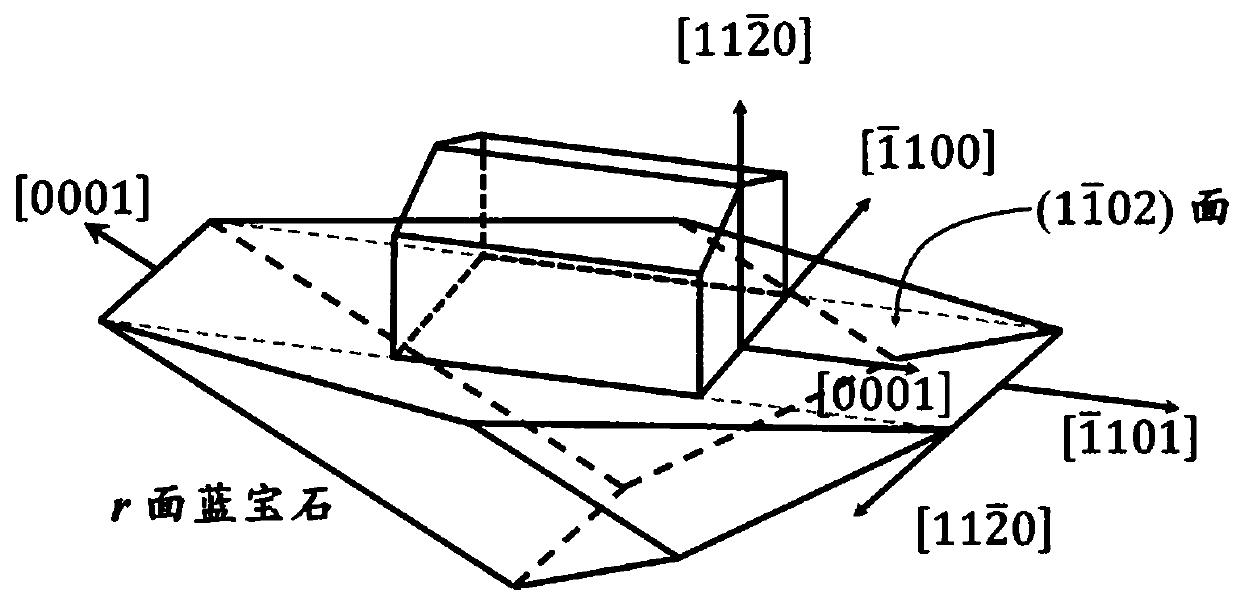

[0031] First, an r-plane sapphire substrate capable of epitaxially growing non-polar III-nitride materials is selected, and then an r-plane patterned sapphire substrate (101) is obtained by etching a sapphire pattern (1011) on the surface of the r-plane sapphire substrate. Among them, the sapphire pattern (1011) is an asymmetric conical structure, that is, the central axis of the conical structure is oriented The direction is inclined. The central axis of the cone is the line connecting the apex of the cone and the center of the bottom surface. The...

Embodiment 2

[0037] A non-polar patterned AlN / sapphire composite substrate is manufactured by the same process as in Example 1, except that the sapphire pattern (1011) is an asymmetric pyramid structure, that is, the pyramid structure is biased towards direction, the central axis of the pyramid is the connection line between the apex of the pyramid and the center of gravity of the bottom surface, and the angle between the central axis and the bottom surface is 60°; the mask layer (102) is deposited by the SiN on the semiconductor deposition technology x film. Other steps are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com