Manufacturing method of magnetic radom access memory unit array and peripheral circuit connecting wires

A technology of random access memory and cell array, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc. It can solve the problems of MRAM device pollution, time-related dielectric breakdown, damage, etc., and achieve the effect of optimizing and improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

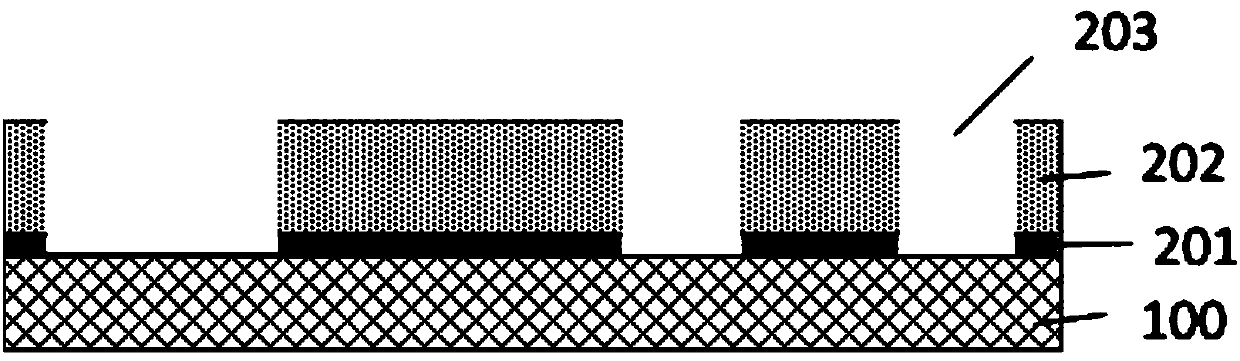

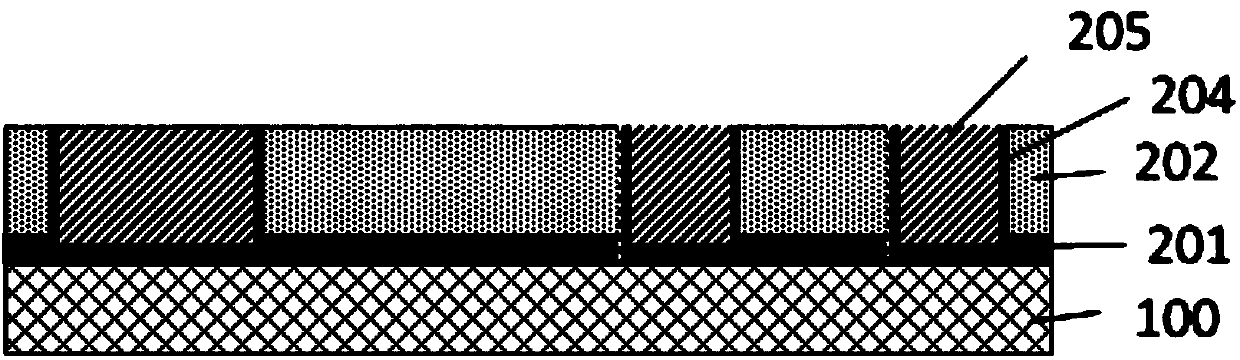

[0037] Step 1: Provide surface finish with metal connection (M x (x>=1) CMOS substrate 100, on which bottom electrode via holes (BEV, Bottom Electrode Via) 203 are formed, and then non-copper metal filling is performed.

[0038] Further, step 1 can be divided into the following forming steps:

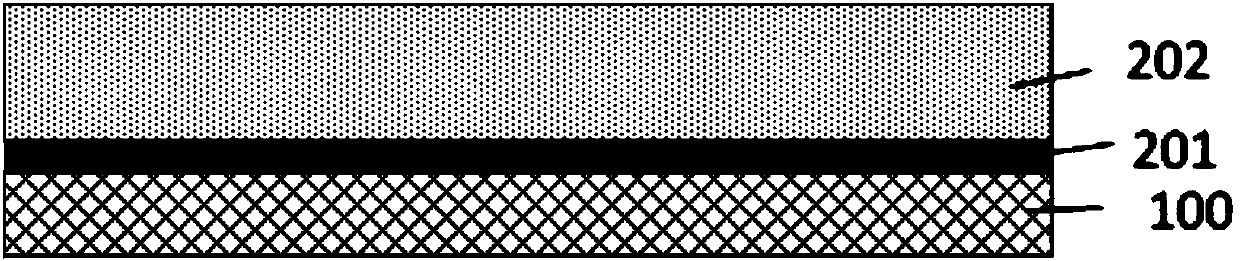

[0039] Step 1.1: Deposit a diffusion barrier layer 201 and a bottom electrode via dielectric 202, as shown in FIG. x ), the diffusion protection layer of copper to the bottom electrode through-hole dielectric 202 can also be used as an etching barrier layer for BEV etching, with a thickness of 10nm-50nm, and the forming material can be SiN, SiC or SiCN. The thickness of the bottom electrode through-hole dielectric 202 is 60nm-150nm, and the forming material can be SiO 2 , SiON or low-k, etc.; wherein, the low dielectric constant (low-k) dielectric refers to a material with a dielectric constant (k) lower than that of silicon dioxide (k=3.9).

[0040] Wherein, the low dielectric const...

Embodiment example 2

[0075] Since BEV is not Cu metal, BEC can also grow together with MTJ multilayer film, or even omit BEC, and use the same MTJ mask, and then use self-alignment to etch MTJ and BEC successively, because BEV uses non-Cu metal , so it doesn't matter that the BEV surface is exposed during the etching process. This saves several steps.

[0076] Compared with the first embodiment, in the second embodiment, no bottom electrode contact is made. The steps are as follows:

[0077] Step 1: Same as Step 1 of Implementation Case 1, such as Figure 1(a)-Figure 1(c) shown;

[0078] Step 2: Same as Step 3 of Implementation Case 1, such as Figure 3(a)-Figure 3(c) shown;

[0079] Step 3: Same as Step 4 of Implementation Case 1, such as Figure 3(d)-Figure 3(h) shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com