Preparation method of high-compactness, high-hardness and high-abrasion-resistance Ti6Al4V blocky alloys

A high-density, high-hardness technology, applied in the field of additive manufacturing, can solve problems such as limited wear resistance, reduced hardness, and cumbersome process procedures, and achieve the effects of low surface roughness, high density, and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This embodiment provides a preparation method for preparing a high hardness and high wear resistance Ti6Al4V bulk alloy, the process of which is as follows:

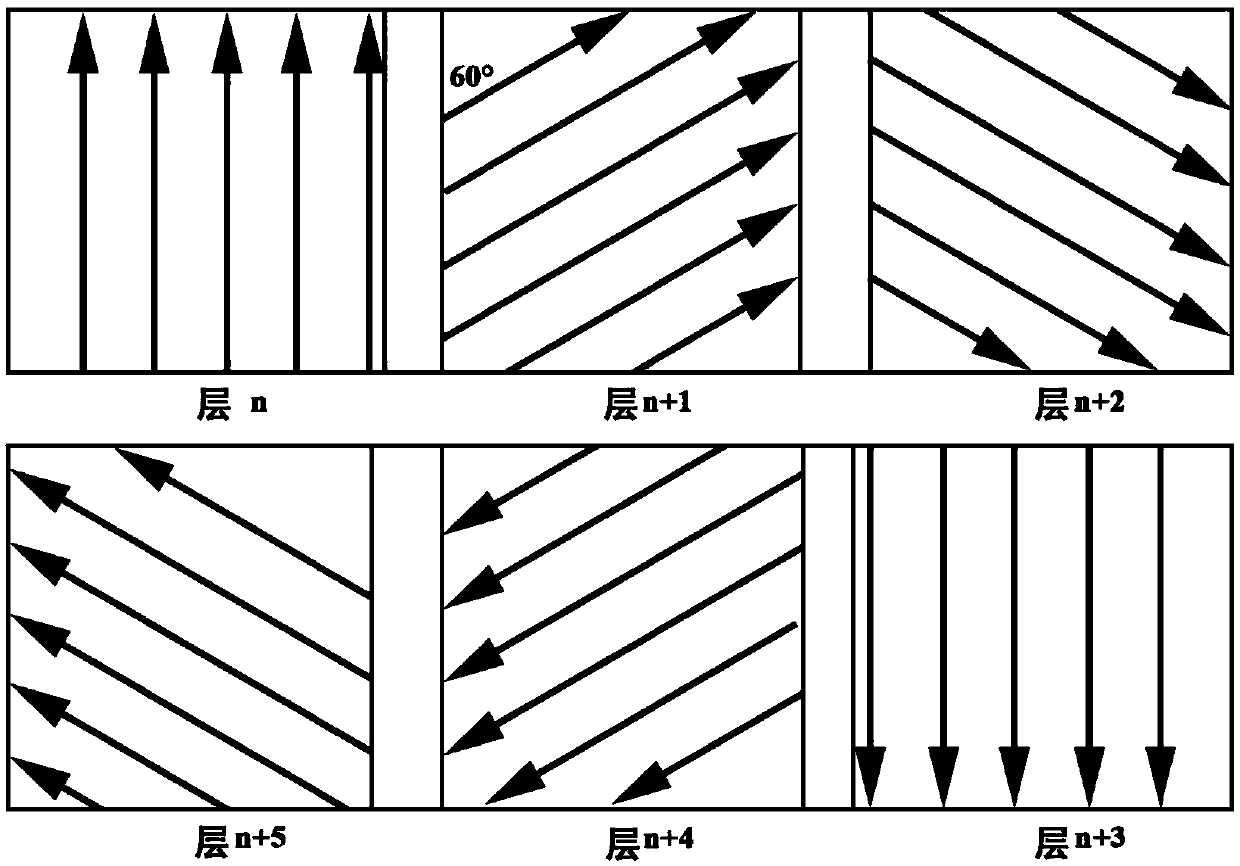

[0057] 1) First, design the 3D model. After importing, the Eplus 3D printing software that comes with the EOS equipment will layer the 3D model at 0.03mm per layer, and build a 2mm support on the Ti6Al4V substrate. In this embodiment, CATIA software is used to design a three-dimensional model.

[0058] 2) Clean the 3D printer machine tool to ensure that it does not contain impurities and other metal powders, and correct the level of the scraper.

[0059] 3) The working cavity of the 3D printing machine tool is protected by the inert gas argon, and the pressure in the cavity is set to 0.4GPa.

[0060] 4), the Ti 6 Al 4 V substrate is heated to 70°C.

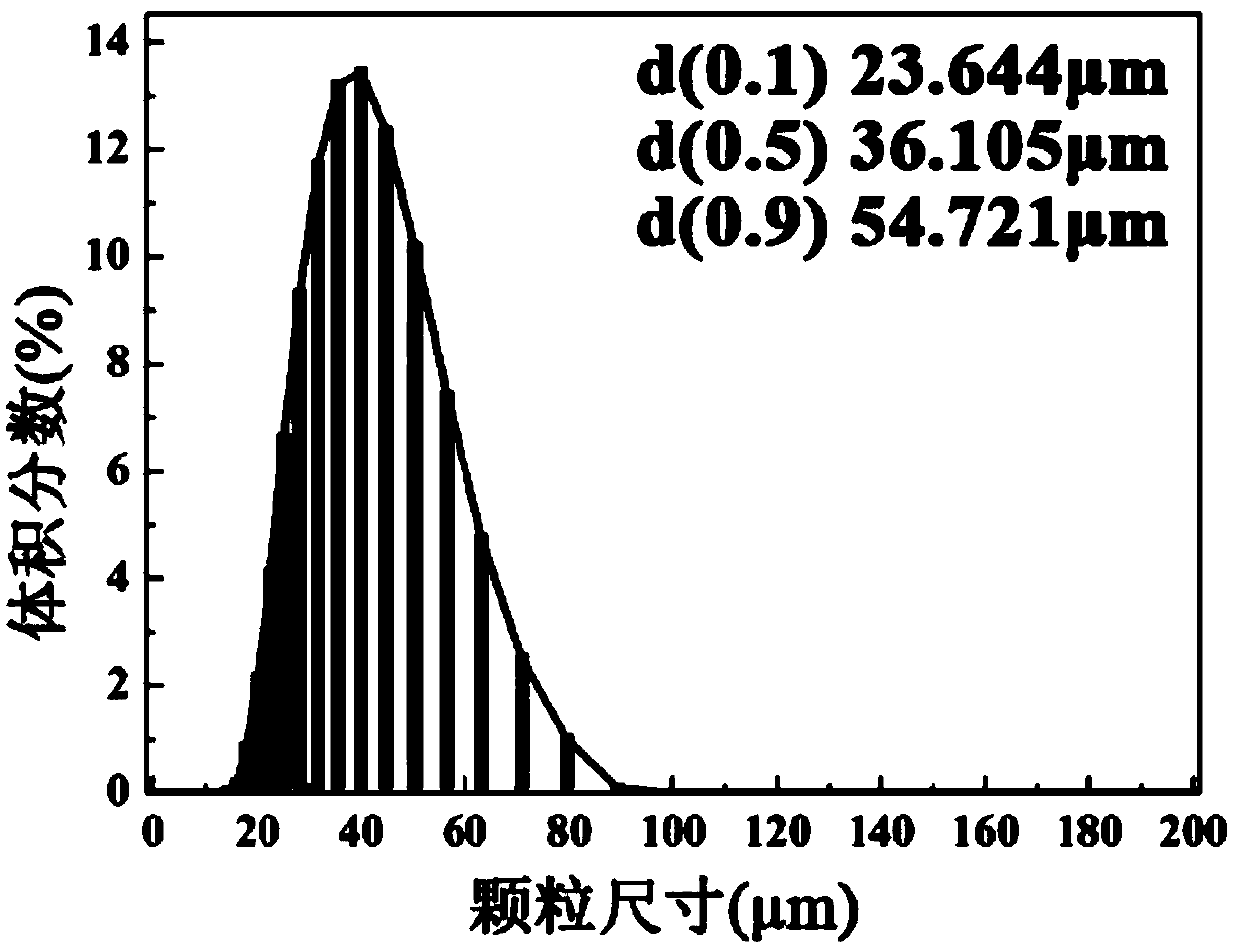

[0061] 5), such as figure 1 Shown: Using Ti 6 Al 4 The particle size of V alloy powder, its d(0.1)=23.644μm, d(0.5)=36.105μm, d(0.9)=54.721μm, its particle siz...

Embodiment 2

[0071] Based on the preparation process of the above-mentioned Example 1, for the preparation of a high-density, high-hardness, high-wear-resistant Ti 6 Al 4 V block alloy, different process parameters are used in this embodiment, the preheating temperature of the substrate is 80°C, the pressure in the cavity is set to 0.5GPa, and the process parameters of laser selective melting are as follows: laser power 260W, scanning speed 1.3m / s, the overlap ratio is 50 μm, and the Ti printed in this example 6 Al 4 V block alloy parts, the density reaches 99.9%, the hardness reaches 412HV, and the wear resistance is 0.37×10 - 3 mm 3 ·N -1 min -1 .

Embodiment 3

[0073] Based on the preparation process of the above-mentioned Example 1, for the preparation of a high-density, high-hardness, high-wear-resistant Ti 6 Al 4 V block alloy, different process parameters are used in this embodiment, the preheating temperature of the substrate is 90°C, the pressure in the cavity is set to 0.6GPa, and the process parameters of laser selective melting are set as follows: laser power 290W, scanning speed 1.4 m / s, the overlap rate is 60μm, and the Ti printed by this embodiment 6 Al 4 V block alloy parts, the density reaches 99.9%, the hardness reaches 410HV, and the wear resistance is 0.36×10 -3 mm 3 ·N -1 min -1 .

[0074] To obtain Ti by this preparation method 6 Al4 V bulk alloy for performance analysis:

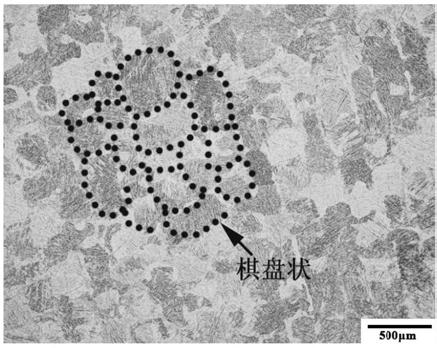

[0075] Figure 3a , Figure 3b For the preparation of Ti 6 Al 4 Scanning electron micrographs of V bulk alloys, such as Figure 3a As shown in the electron microscopy photos, it can be seen that a checkerboard structure is formed pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com