Hydrophobic nanogel and preparation method thereof

A hydrophobic and gel technology, applied in the field of nanomaterials, can solve the problems of less hydrophobic nanogel preparation and mechanism research, and achieve the effects of high safety, increased adsorption capacity, and uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

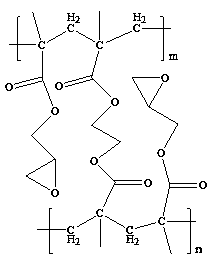

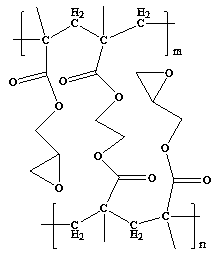

Image

Examples

Embodiment 1

[0022] Based on the total amount of all raw materials as 100%, a mixed solution containing 0.59% glycidyl methacrylate, 0.41% ethylene glycol dimethacrylate, 0.5% sodium lauryl sulfate and 98.41% deionized water Mix well in a glass bottle by ultrasonic mixing to form an oil-in-water emulsion. Place it in a water bath temperature of 70°C, and simultaneously add 3% of the total mass of both glycidyl methacrylate and ethylene glycol dimethacrylate. Ammonium persulfate and 6% N,N,N',N' -Tetramethylethylenediamine catalyst, continue to stand for 8 min at 70℃, and quickly cool to room temperature after the reaction is completed, to obtain the crude polyglycidyl methacrylate nanogel, and the obtained polyglycidyl methacrylate The crude ester nanogel was tested with the Malvern ZS90 particle size analyzer to test the particle size of the nanogel. The obtained nanogel has a particle size of 10~190 nm, an average particle size of about 41 nm, and a Zeta potential of about -40 mV. The in...

Embodiment 2

[0024] Based on the total amount of all raw materials as 100%, a mixed solution containing 2.8% glycidyl methacrylate, 0.2% ethylene glycol dimethacrylate, 2% sodium lauryl sulfate and 94.73% deionized water Mix well by ultrasonic in a glass bottle to form an oil-in-water emulsion. Place it at a water bath temperature of 50°C, and simultaneously add 3% persulfuric acid with the total mass of glycidyl methacrylate and ethylene glycol dimethacrylate. Ammonium and 6% N,N,N',N' -Tetramethylethylenediamine catalyst, continue to stand for reaction at 50°C for 10 min, and quickly cool to room temperature after the reaction is completed, to obtain polyglycidyl methacrylate nanogel. The prepared polyglycidyl methacrylate nanogel was tested for the particle size of the nanogel with a Malvern ZS90 particle size analyzer. The obtained nanogel has a particle size of 40-250 nm, an average particle size of about 90 nm, a Zeta potential of -49 mV, and a dispersion index of 0.17.

Embodiment 3

[0026] Based on the total amount of all raw materials as 100%, a mixed solution containing 4.93% glycidyl methacrylate, 0.07% ethylene glycol dimethacrylate, 2.5% sodium lauryl sulfate and 92.41% deionized water Mix well by ultrasonic in a glass bottle to form an oil-in-water emulsion. Place it at a temperature of 70°C in a water bath, and simultaneously add 0.6% persulfuric acid with the total mass of glycidyl methacrylate and ethylene glycol dimethacrylate. Ammonium and 1.2% N,N,N',N' -Tetramethylethylenediamine catalyst, continue to stand for reaction at 70°C for 8 min, and quickly cool to room temperature after the reaction is completed to obtain polyglycidyl methacrylate nanogel. The prepared polyglycidyl methacrylate nanogel was tested for the particle size of the nanogel with a Malvern ZS90 particle size analyzer. The obtained nanogel has a particle size of 30-220 nm, an average particle size of about 70 nm, a Zeta potential of about -40 mV, and a dispersion index of ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com