Granulation method of silicon carbide composite ceramic material

A technology of composite ceramics and silicon carbide, which is applied in the field of ceramic materials, can solve the problems of large density difference between metal powder and ceramic powder, uniform mixing of organic binder, high production dimensional accuracy, etc., and achieve less machining and stable size , The effect of high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

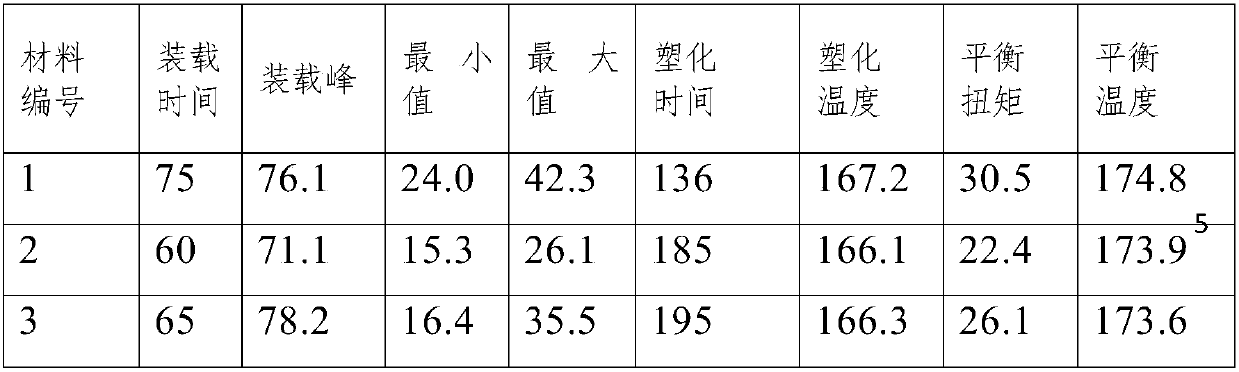

Embodiment 1

[0041] The present embodiment uses the raw material of following mass percentage:

[0042] Metal powder granulation: 304L powder 9.2KG, organic binder 0.8KG, 304L powder particle size is 8um.

[0043] Ceramic granulation: 5KG of β-silicon carbide powder, 2KG of β-alumina powder, 3KG of organic binder, in which the particle size of silicon carbide is 5um and the particle size of alumina is 3um.

[0044] The composition of the organic binder: POM 88wt%, HDPE 7.5wt%, EVA 2wt%, PE wax 1wt%, SA 1.5wt%.

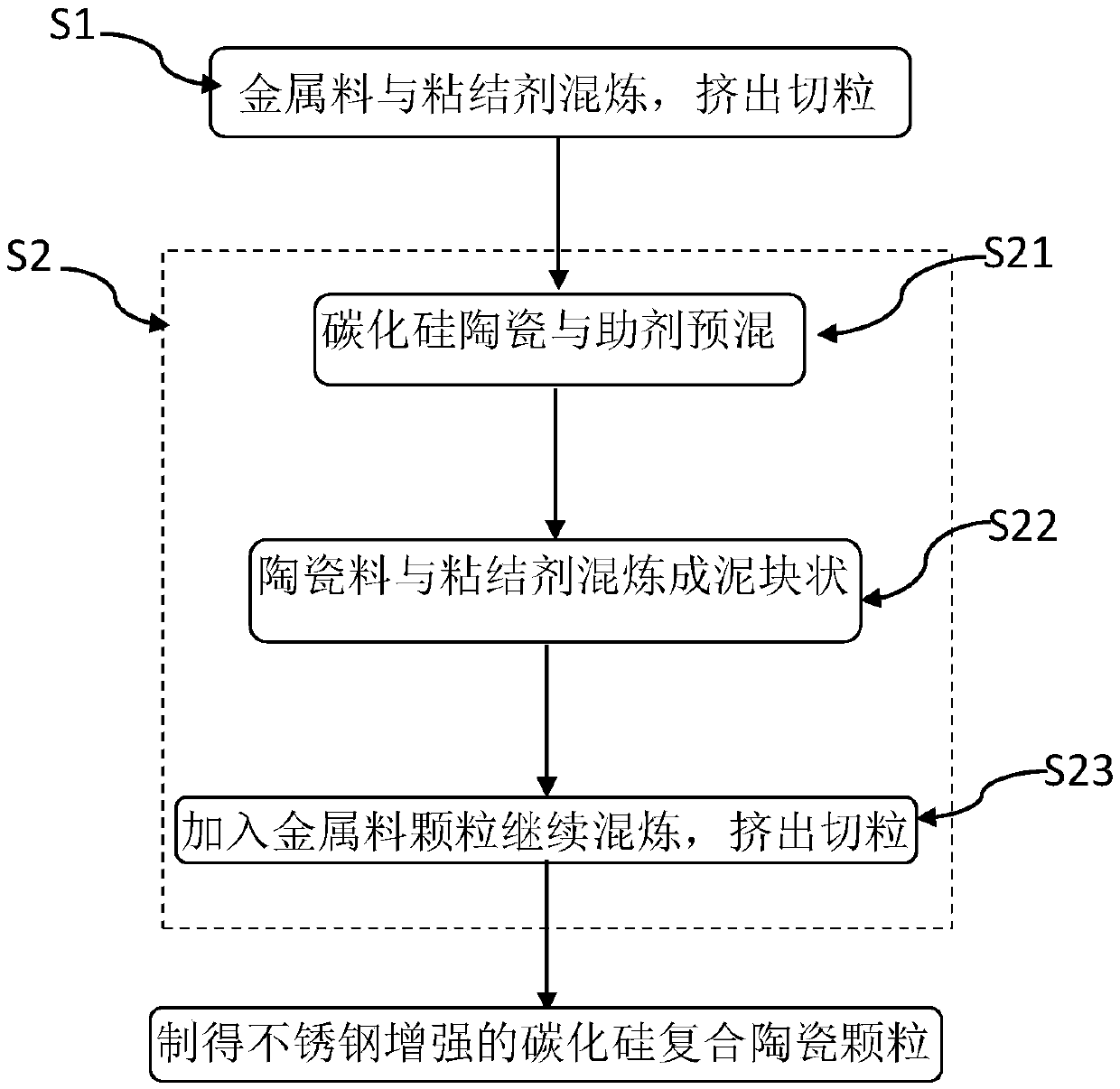

[0045] The granulation method of the present embodiment combines figure 1 Shown as:

[0046] Step 1: Metal powder granulation: set the temperature of the first to fourth zones of the mixer extruder integrated machine to 140-150-160-200°C, put 304L powder and organic binder into the mixer, and the mixing speed is 5r / min, kneading for 30min, after the material becomes a paste, the temperature in the fourth zone is lowered to 160°C, extruded and pelletized at the same time, the ext...

Embodiment 2

[0053] The present embodiment uses the raw material of following mass percentage:

[0054] Metal powder granulation: SU-316 powder 9.0KG, organic binder 1.0KG, SU-316 powder particle size 10um.

[0055] Ceramic granulation: β-silicon carbide powder 5KG, β-alumina powder 2.5KG, organic binder 2.5KG, of which silicon carbide particle size is 6um and alumina particle size is 3.5um.

[0056] The composition of the organic binder: POM 85wt%, HDPE 8wt%, EVA 2wt%, PE wax 2wt%, SA 3wt%.

[0057] The granulation method of the present embodiment combines figure 1 Shown as:

[0058] Step 1: Metal powder granulation: set the temperature of the first to fourth zones of the mixer extruder integrated machine to 140-150-160-200°C, put SU-316 powder and organic binder into the mixer, and mix After 30 minutes, after the material becomes a paste, the temperature in the fourth zone is lowered to 160°C, and the extrusion and pelletizing are carried out at the same time. The extrusion rate is 10...

Embodiment 3

[0065] The present embodiment uses the raw material of following mass percentage:

[0066] Metal powder granulation: SU-304 powder 9.5KG, organic binder 0.5KG, SU-304 powder particle size 12um.

[0067] Ceramic granulation: 4.5KG of β-silicon carbide powder, 3KG of β-alumina powder, 2.5KG of organic binder, among which the particle size of silicon carbide is 7um and the particle size of alumina is 5um.

[0068] The composition of the organic binder: POM 87wt%, HDPE 7wt%, EVA 3wt%, PE wax 1.5wt%, SA 1.5wt%.

[0069] The granulation method of the present embodiment combines figure 1 Shown as:

[0070] Step 1: Metal powder granulation: set the temperature of the first to fourth zones of the mixer extruder integrated machine to 140-150-160-200°C, put SU-304 powder and organic binder into the mixer, and mix After 60 minutes, when the material is in paste form, the temperature in the fourth zone is lowered to 160°C, extruded and pelletized at the same time, the extrusion speed is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com