Preparation method and application of nitrogen-doped peel based porous carbon material

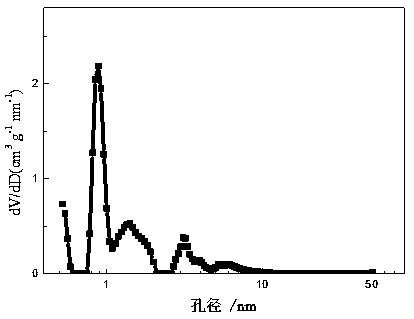

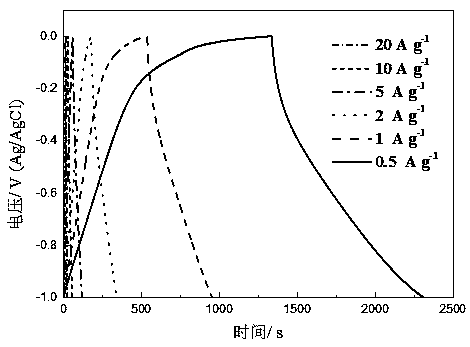

A nitrogen doping and peeling technology, applied in chemical instruments and methods, manufacturing of hybrid/electric double layer capacitors, inorganic chemistry, etc., can solve the problems of decreased electric double layer capacitance, loss of material specific surface area, etc., and achieve a suitable pore size distribution. , low cost and high cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] After peeling the peel, cleaning and drying, weigh 3 g of peel and 0.5 g of melamine and mix it in a small beaker, add deionized water, put it into an ultrasonic cell pulverizer, and use an ultrasonic probe for processing (power 300 W, interval 2 s work, the treatment time is 15 min) to obtain a viscous mixture. After drying for 8 h, under nitrogen atmosphere, the temperature was raised to 400 °C at 2 °C / min, kept for 2 h, and cooled to room temperature to obtain nitrogen-doped peel base carbon; the nitrogen-doped peel-based carbon and the activator potassium bicarbonate were treated with a ball mill for 30 min in a mass ratio of 1:5 (300 rpm, forward rotation 15 min, reverse rotation 15 min), and the obtained mixture was placed in In a tube furnace, under a nitrogen atmosphere, the temperature was raised to 850 °C at 5 °C / min, kept for 2 h, cooled to room temperature, and 1 mol L -1 Wash with hydrochloric acid at 50°C for 2 h, wash with water until neutral, and then d...

Embodiment 2

[0031] After peeling, cleaning, and drying the peel, weigh 3 g of peel and 1 g of melamine and mix them in a small beaker, add deionized water, put them into an ultrasonic cell pulverizer, and use an ultrasonic probe for processing (power 300 W, interval 2 s work, the treatment time is 15 min) to obtain a viscous mixture. After drying for 8 h, under nitrogen atmosphere, the temperature was raised to 400 °C at 2 °C / min, kept for 2 h, cooled to room temperature, and nitrogen-doped peel was obtained. base carbon; nitrogen-doped fruit peel-based carbon and activator potassium bicarbonate were treated with a ball mill for 30 min (300 rpm, forward rotation 15 min, reverse rotation 15 min) at a mass ratio of 1:5, and the resulting mixture was placed in In a tube furnace, under a nitrogen atmosphere, the temperature was raised to 850 °C at 5 °C / min, kept for 2 h, cooled to room temperature, and 1 mol L -1 Pickling with hydrochloric acid for 2 h, washing with water until neutral, and ...

Embodiment 3

[0033] After peeling, cleaning, and drying the peel, weigh 3 g of peel and 2 g of melamine and mix them in a small beaker, add deionized water, put them into an ultrasonic cell pulverizer, and use an ultrasonic probe for processing (power 300 W, interval 2 s work, the treatment time is 15 min) to obtain a viscous mixture. After drying for 8 h, under nitrogen atmosphere, the temperature was raised to 400 °C at 2 °C / min, kept for 2 h, cooled to room temperature, and nitrogen-doped peel was obtained. base carbon; nitrogen-doped fruit peel-based carbon and activator potassium bicarbonate were treated with a ball mill for 30 min (300 rpm, forward rotation 15 min, reverse rotation 15 min) at a mass ratio of 1:5, and the resulting mixture was placed in In a tube furnace, under a nitrogen atmosphere, the temperature was raised to 850 °C at 5 °C / min, kept for 2 h, cooled to room temperature, and 1 mol L -1 Pickling with hydrochloric acid for 2 h, washing with water until neutral, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com