Automatic punching device and assembly line process thereof

A stamping device and automatic technology, applied in the field of stamping processing, can solve problems such as low efficiency, achieve the effects of easy operation, saving labor costs, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

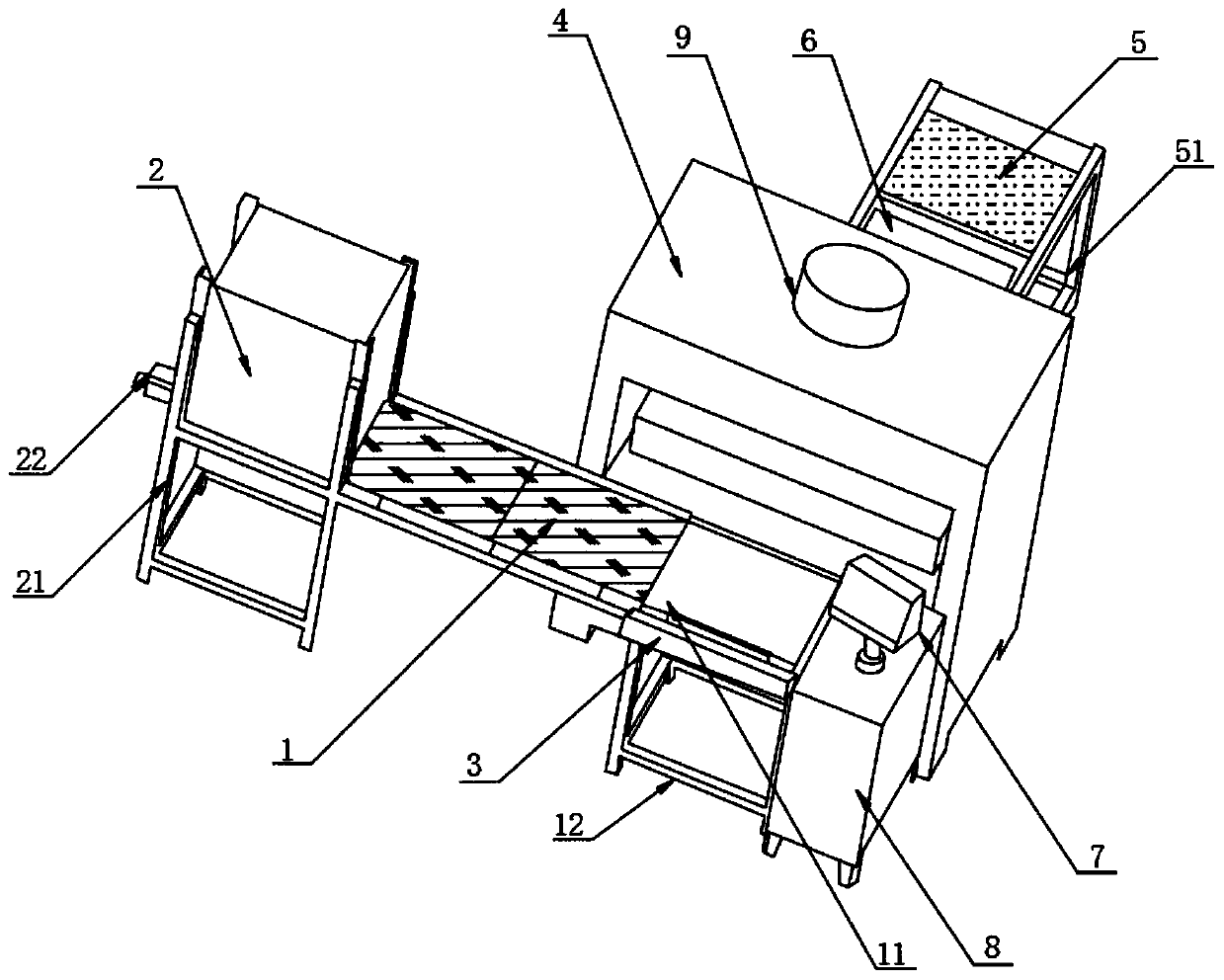

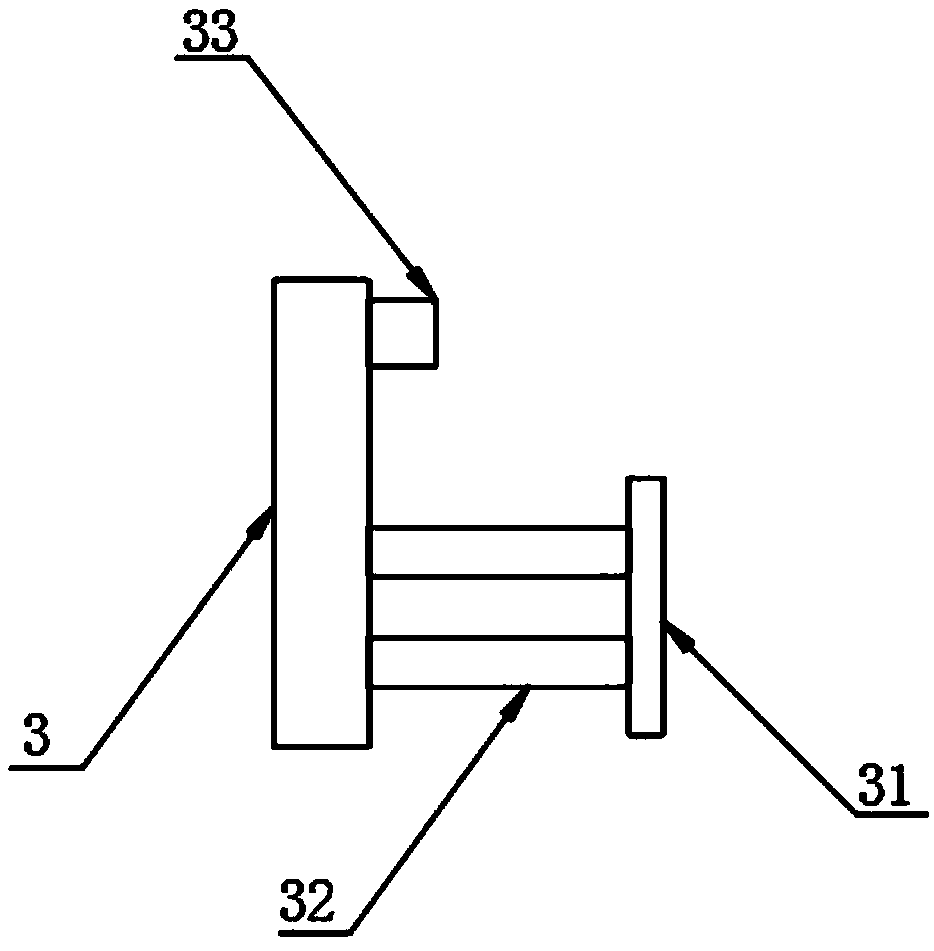

[0028] The present invention provides Figure 1-4 The automatic punching device and its assembly line process shown include an input transmission panel 1. One side of the input transmission panel 1 is provided with a storage housing 2, and one end of the input transmission panel 1 is provided with a front side surface Feeding mounting plate 3, the input transmission panel 1 is provided with a stamping device 4 on the rear side of one end. The stamping device 4 includes a stamping housing 41, a stamping panel 42, a stamping bottom plate 43, a stamping top plate 44, a laser sensor 45, and a hydraulic cylinder 46. The hydraulic rod 47, the hydraulic motor 48 and the supporting seat 49. The punching device 4 is provided with a discharge transmission panel 5 on the outside, the top of the discharge transmission panel 5 is provided with a top plate 6, and the feeding transmission panel 1 side A control device 7 is provided, a support housing 8 is provided at the bottom of the contr...

Embodiment 2

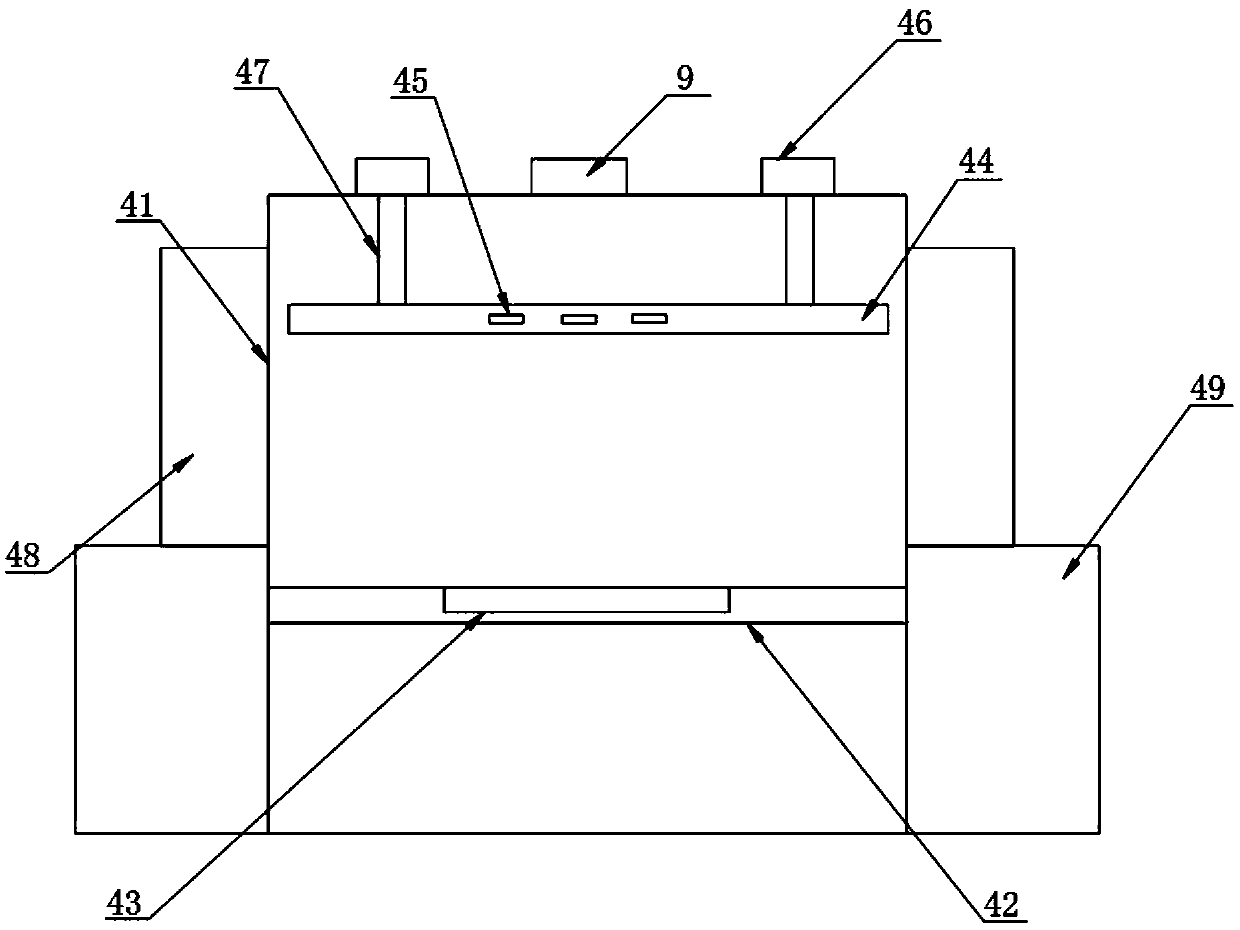

[0034] The punching shell 41 is hollow, and the punching shell 41 is provided with a punching panel 42 inside, and the punching panel 42 is connected to the feed transmission panel 1, and the punching panel 42 is provided with a punching bottom plate 43. The top of the stamping panel 42 is provided with a stamping top plate 44, the front and rear surfaces of the stamping top plate 44 are evenly provided with laser sensors 45, the top of the stamping housing 41 is provided with a hydraulic cylinder 46, the stamping top plate 44 and the hydraulic cylinder 46 A hydraulic rod 47 is provided therebetween, and the hydraulic rod 47 is in transmission connection with the hydraulic cylinder 46. A hydraulic motor 48 is provided on the outer side of the stamping housing 41. 48 is provided with a support base 49 at the bottom.

[0035] The beneficial effects of this embodiment: the material enters the stamping panel 42 in the stamping shell 41, the laser sensor 45 detects the type of the she...

Embodiment 3

[0037] The bottom of the discharging transmission panel 5 is provided with a discharging support frame 51, and the discharging transmission panel 5 is fixedly connected with the punching panel 42.

[0038] The top plate 6 is arranged outside the punching device 4, the bottom of the top plate 6 is evenly provided with a camera 61, one end of the 6 is provided with a hair dryer 62, and the bottom of the hair dryer 62 is connected with a blowing nozzle 63.

[0039] The control device 7 includes a PLC controller, a wireless data transmission module, a data processing module, and a data storage module. The control device 7 is provided with a touch screen on the surface, and the control device 7 is connected to the buzzer 9 through a transmission cable. And control the buzzer 9.

[0040] The beneficial effects of this embodiment: the punched sheet enters the discharge transmission panel 5 from the punching housing 41, and the camera 61 captures the size and model of the punched sheet and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com