Process device and process method of liquid phase desulfurization of hydrogen sulfide and sulfur dioxide

A technology for sulfur dioxide and process equipment, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve the problems that the purity of sulfur products cannot meet the market demand and increase the operating cost of the equipment, shorten the reaction time, and prevent the deposition and junction. Scaling, the effect of increasing the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

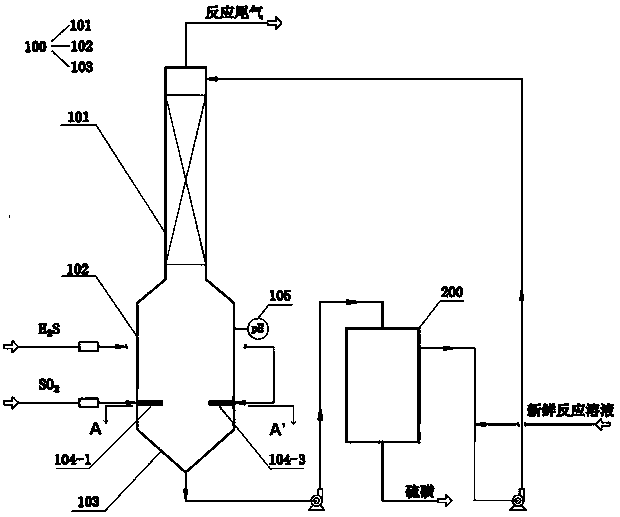

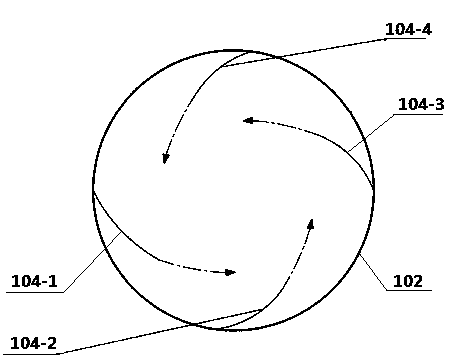

[0056] Process units for liquid phase desulfurization of hydrogen sulfide and sulfur dioxide, such as figure 1 As shown, the reactor 100 and the separator 200 are included, and the reactor is followed by the tail gas absorption zone 101, the reaction zone 102, and the settling zone 103 from top to bottom; the diameter ratio of the tail gas absorption zone 101 and the reaction zone 102 is 1:2 , the two are connected by a cone-shaped variable diameter. The tail gas absorption zone 101 is equipped with a solid tongue tray; four gas inlet pipes 104-1, 104-2, 104-3 and 104-4 are arranged symmetrically on the reaction zone 102, as figure 2 As shown, all gas inlet pipes are arc-shaped pipes, and the radian and position of each gas inlet pipe are set so that the gas ejected is close to the center line of the reaction zone; the wall of the reaction zone 102 is also provided with a pH online monitor 105, the settling zone 103 is in an inverted conical shape, the bottom outlet of which...

Embodiment 2

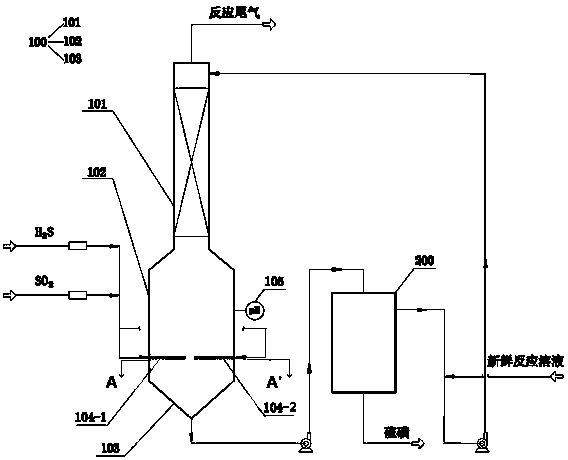

[0058] A process device for reactive desulfurization of hydrogen sulfide and sulfur dioxide, such as image 3 As shown, the difference from the process device in Example 1 is that two gas inlet pipes 104-1 and 104-2 are arranged symmetrically on the reaction zone 102, as Figure 4 As shown, the gas inlet pipes 104-1 and 104-2 are a section of straight pipe + an arc pipe, and other structural settings are the same as those in Embodiment 1.

Embodiment 3

[0060] use figure 1 The processing method of hydrogen sulfide and sulfur dioxide reactive desulfurization in the shown process device is as follows:

[0061] Pure SO 2 The gas is passed into the reaction zone 102 of the reactor 100 through the gas inlet pipes 104-1 and 104-3, and the aqueous solution of the organic basic compound is housed in the reactor 100 as the reaction solution, SO 2 The gas enters the reaction zone 102 through the gas inlet pipes 104-1 and 104-3, and is close to the center line of the reaction zone, driving the reaction solution in the reactor 100 to rotate, realizing the self-stirring effect of the liquid in the reactor 100, Good for SO 2 Uniform dispersion of gas in the reaction solution, and greatly increased SO 2 The dissolution rate of the gas in the reaction solution, when the pH online monitor 105 shows 6.5, start to feed pure H into the reaction zone 102 2 S gas is passed through the gas inlet pipes 104-2 and 104-4, and the reaction solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com