Aspirin tablet and preparation method thereof

A technology of aspirin tablets and aspirin, which is applied in the field of aspirin tablets and its preparation, can solve the problems of general compressibility of aspirin raw materials, unfavorable industrial production, and high proportion of components, and achieve industrial production, high dissolution rate, and stable quality Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

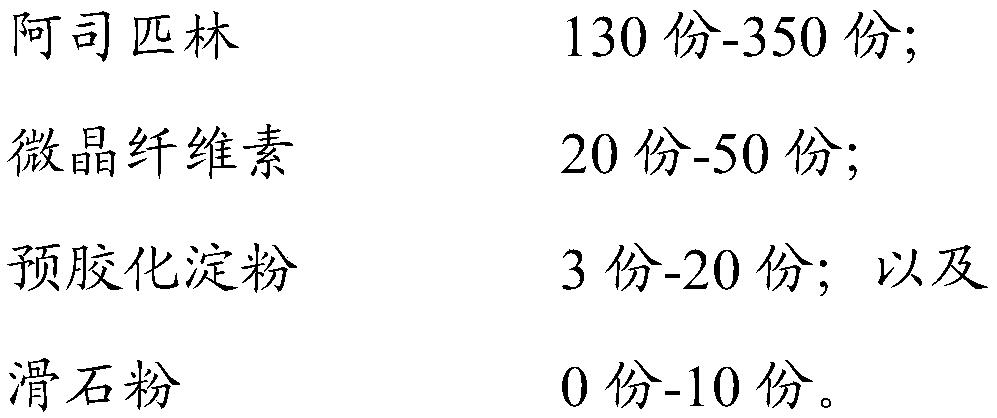

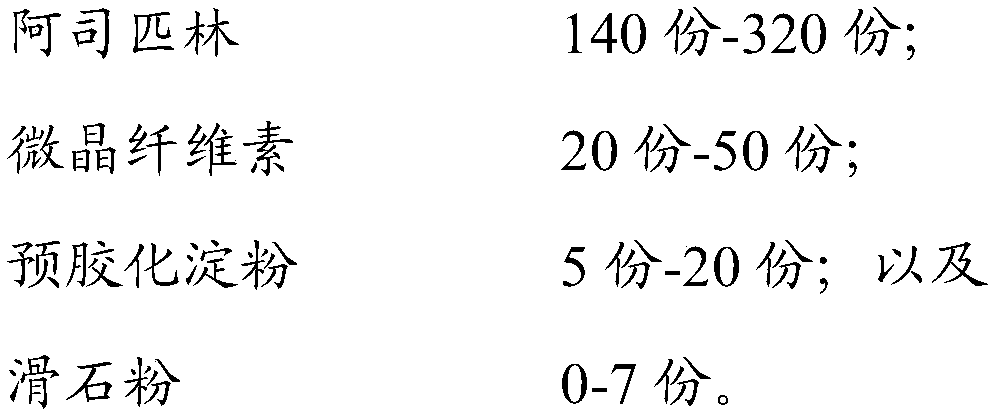

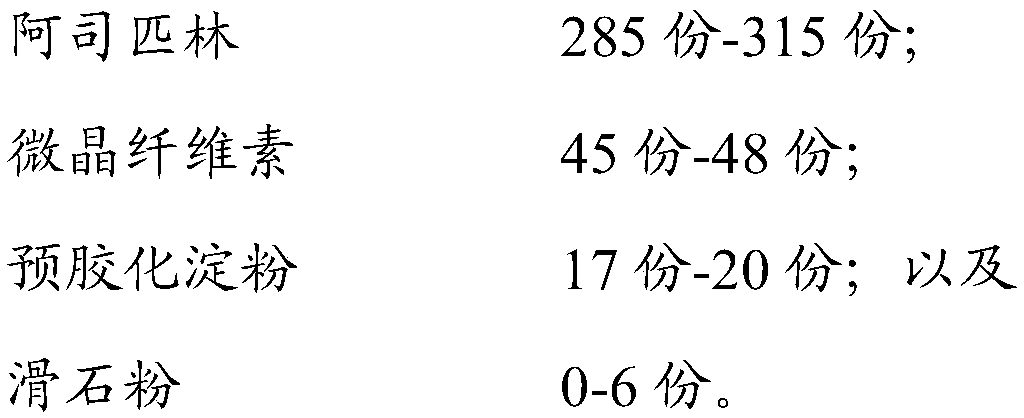

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a kind of aspirin tablet, totaling 3 million tablets, which includes the following raw materials in parts by weight: 300 kg of aspirin, 46 kg of microcrystalline cellulose ZW102 type, 18 kg of pregelatinized starch, and 6 kg of talcum powder.

[0036] The preparation method of the aspirin tablet of the present embodiment, comprises the steps:

[0037] S1, weigh each raw material according to the raw material composition of the aspirin tablet in this embodiment.

[0038] S2, use a fast granulator to pass the aspirin raw material through a 1.5mm mesh stainless steel screen at a speed of 600r / min, and granulate to obtain whole granules of aspirin, so as to improve the fluidity, compressibility and formability of the material. The yield of aspirin in this step is 99.6%, material balance: 99.5-100.0%.

[0039] S3, using a GM-1500 three-dimensional mixer to mix the whole aspirin with microcrystalline cellulose, pregelatinized starch, and talcum powde...

Embodiment 2

[0043] The present embodiment provides an aspirin tablet, 600,000 tablets in total, including the following raw materials in parts by weight: 180 kg of aspirin, 30 kg of microcrystalline cellulose ZW101 type, 18 kg of pregelatinized starch, and 6 kg of talcum powder.

[0044] The preparation method of the aspirin tablet of the present embodiment, comprises the steps:

[0045] S1, weigh each raw material according to the raw material composition of the aspirin tablet in this embodiment.

[0046] S2, the aspirin raw material is passed through a 1.5mm mesh stainless steel screen by a fast granulation machine at a speed of 600r / min, and the granules are sized to obtain whole granules of aspirin. The yield of aspirin in this step is 99.8%, material balance: 99.5-100.0%.

[0047] S3, using a GM-1500 three-dimensional mixer to mix the whole aspirin with microcrystalline cellulose, pregelatinized starch, and talcum powder at a speed of 6 r / min and a mixing time of 15 min. The yield ...

Embodiment 3

[0050] This embodiment provides a kind of aspirin tablet, totaling 300,000 tablets, which includes the following raw materials in parts by weight: 150 kg of aspirin, 24 kg of microcrystalline cellulose ZW102 type, 6 kg of pregelatinized starch, and 4.5 kg of talcum powder.

[0051] The preparation method of the aspirin tablet of the present embodiment, comprises the steps:

[0052] S1, weigh each raw material according to the raw material composition of the aspirin tablet in this embodiment.

[0053] S2, the aspirin raw material is passed through a 1.5mm mesh stainless steel screen by a fast granulation machine at a speed of 600r / min, and the granules are sized to obtain whole granules of aspirin. The yield of aspirin in this step is 99.8%, material balance: 99.5-100.0%.

[0054]S3, using a GM-1500 three-dimensional mixer to mix the whole aspirin with microcrystalline cellulose, pregelatinized starch, and talcum powder at a speed of 6 r / min and a mixing time of 15 min. The y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com