DHA jelly sweet and preparation method thereof

A technology of jelly candy and gelling agent, which is applied in the field of DHA preparations, can solve the problems of difficult control of embedding quality, small proportion of crude oil, and low DHA content, so as to facilitate large-scale production, improve human body function, and expand Market Space Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

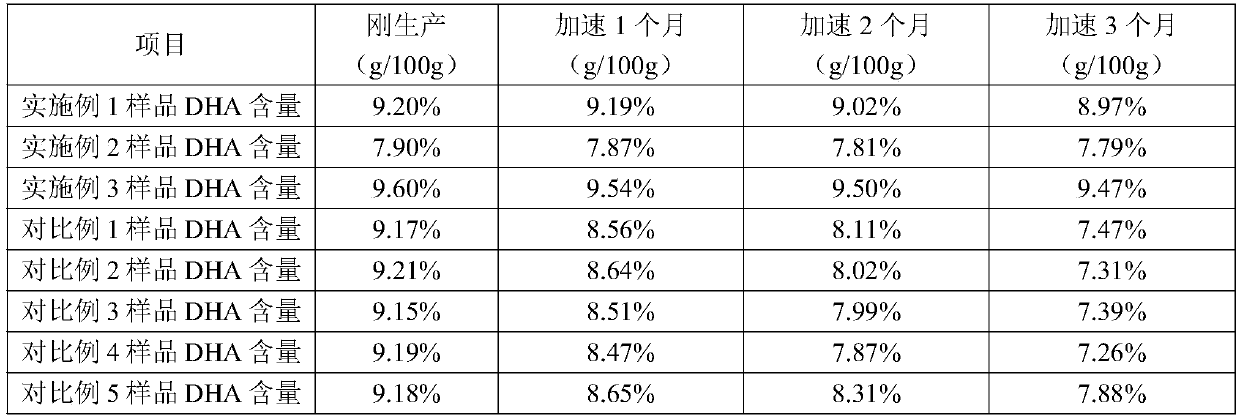

Examples

preparation example Construction

[0037] The preparation method of the DHA jelly jelly provided by the present invention comprises: stirring and mixing DHA oil, complex gelling agent solution and sweetener solution evenly, and adjusting the pH value of the obtained mixed solution to 3-4, and then mixing the obtained material The liquid is solidified and formed to obtain DHA gel jelly; the gelling agent contained in the composite gelling agent solution is a mixture of at least one of gelatin and pectin, gum arabic and carrageenan, and the content of the gelatin is the same as that of fruit. The weight ratio of the total content of gum, gum arabic and carrageenan is 1:(0.1-1.5), preferably 1:(0.4-0.8).

[0038]As mentioned above, the gelling agent contained in the composite gelling agent solution is a mixture of at least one of gelatin and pectin, gum arabic and carrageenan, that is, the composite gel can be gelatin+pectin, Gelatin + Gum Arabic, Gelatin + Carrageenan, Gelatin + Pectin + Gum Arabic, Gelatin + Pec...

specific Embodiment approach

[0046] According to a specific embodiment of the present invention, the preparation method of the DHA jelly candy comprises the following steps:

[0047] (1) Put the gelling agent and water in a sol tank, and heat to 80-220°C, preferably 100-140°C, stir and mix, so that the gelling agent is fully dissolved in water to obtain a composite gelling agent solution; Put the sweetener and water in the sol tank, and heat to 90-200°C and stir and mix, so that the sweetener is fully dissolved in the water to obtain a sweetener solution;

[0048] (2) Add DHA oil into the composite gel solution, stir evenly to obtain the DHA gel mixture, then add the sweetener solution into it, stir evenly, then adjust the pH value of the resulting mixed solution to 3-4, add Additives, stir evenly to obtain feed liquid;

[0049] (3) The feed liquid is poured into a mold plate by a pouring machine to form it, and the mold plate is demolded after drying, and oiled or powdered to obtain DHA jelly candy.

...

Embodiment 1-5

[0053] (1) Place the gelling agent and water in the sol tank, and heat and stir to mix, so that the gelling agent is fully dissolved in water to obtain a composite gelling agent solution; place the sweetener and water in the sol tank, and heat Stir and mix, so that the sweetener is fully dissolved in water to obtain a sweetener solution;

[0054] (2) Add DHA oil into the composite gel solution, stir evenly to obtain the DHA gel mixture, then add the sweetener solution into it, stir evenly, then adjust the pH value of the resulting mixed solution to 3-4, add Additives, stir evenly to obtain feed liquid;

[0055] (3) Dry the mold plate until the moisture content is lower than 6%, then pour the material liquid into the dried mold plate through the pouring machine to form, after the pouring is completed, place the mold plate in the drying room to dry, and demould , oiled or powdered, and packaged to obtain DHA jelly gum. Wherein, the kind and consumption of each raw material and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com