Anodizing device and method for anodizing aluminum powder under neutral condition through anodizing device

An anodic oxidation and aluminum powder technology, which is applied in anodic oxidation, electrolytic components, transportation and packaging, etc., can solve the problems of weak adsorption of additives, high cost, complicated process, etc., and achieve the effect of improving stability and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

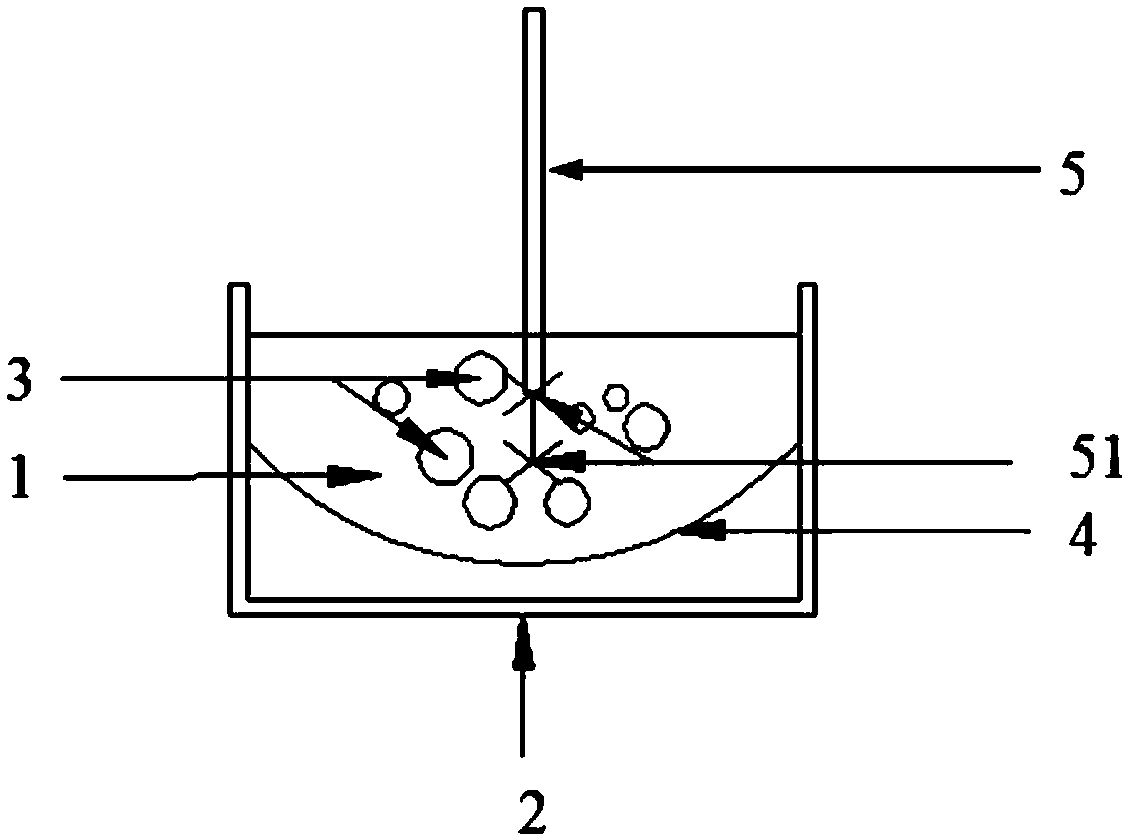

[0070] This embodiment provides a kind of anodizing device (for its schematic diagram, refer to figure 1 ), the anodizing device includes a cathode tank 2, a separation bag 4 and an anode 5, the cathode tank 2 contains a neutral electrolyte 1, the separation bag 4 is immersed in the neutral electrolyte 1, and the separation bag 4 wraps the metal The powder 3 prevents the metal powder 3 from contacting the cathode cell 2;

[0071] The anode 5 includes a metal paddle part 51 , and at least the metal paddle part 51 of the anode 5 is inserted into the separation bag 4 immersed in the neutral electrolyte 1 .

Embodiment 2

[0073] This embodiment provides a method for anodizing aluminum powder under neutral conditions using the anodizing device described in Embodiment 1, the method comprising the following steps:

[0074] The first step is to select a 325-mesh filter bag and place it in the cathode tank filled with neutral electrolyte. The pores of the filter bag are smaller than the particle size of the aluminum powder, which can ensure that the aluminum powder does not touch the cathode and avoid short circuit between the cathode and anode. Aluminum powder with 35% neutral electrolyte quality is dispersed in the filter bag, and the anode metal stirring paddle part is inserted into the filter bag;

[0075] The second step is to start the anode with stirring function (that is, the anode with metal stirring paddle parts), the stirring speed is 450rpm, connect the DC power supply, control the voltage at 95V, and the anode current density is 3A / 100cm 2 , the temperature is 45°C, the pH value of the ...

Embodiment 3

[0080] This embodiment provides a method for anodizing aluminum powder under neutral conditions using the anodizing device described in Embodiment 1, the method comprising the following steps:

[0081] The first step is to select an 800-mesh filter bag and place it in the cathode tank filled with neutral electrolyte. The pores of the filter bag are smaller than the particle size of the aluminum powder, which can ensure that the aluminum powder does not touch the cathode and avoid short circuit between the cathode and anode. The aluminum powder with 10% of the mass of the electrolyte is dispersed in the filter bag, and the metal stirring paddle part of the anode is inserted into the filter bag;

[0082] The second step is to start the anode with stirring function (that is, the anode with metal stirring paddle parts), the stirring speed is 500rpm, connect the DC power supply, control the voltage at 50V, and the anode current density is 1A / 100cm 2 , the temperature is 40°C, the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com