Method for modifying SnBi series hypoeutectic alloy and obtained alloy

A hypoeutectic and alloy technology, which is applied in the field of modification of SnBi series hypoeutectic alloys, can solve the problems of increasing the Sn-Bi eutectic phase ratio and not reaching it, and achieves the promotion of alloy nucleation rate, elimination of particles, The effect of suppressing precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

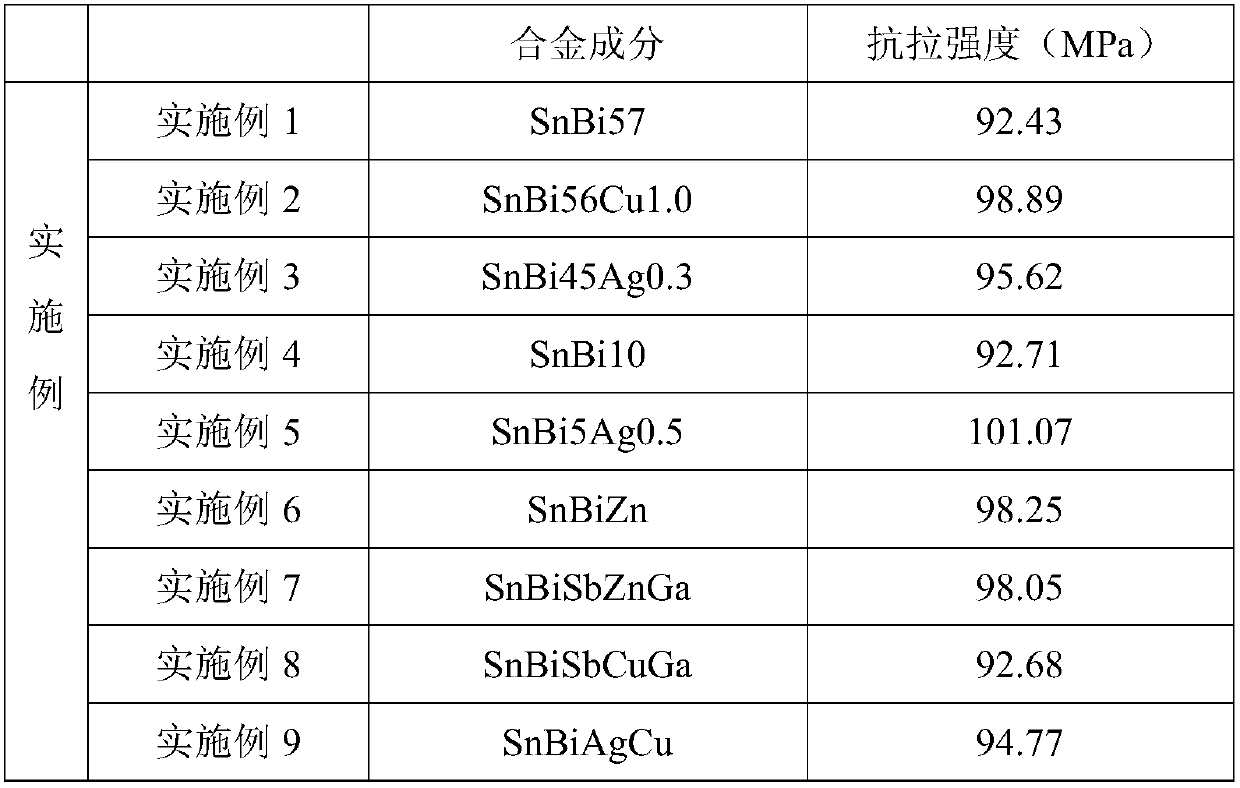

Embodiment 1

[0038] A method for modifying a SnBi hypoeutectic alloy by using a topological short-range ordered structure. The method induces the transformation of the topological short-range ordered structure through temperature elements. The specific operation steps are: select the SnBi57 hypoeutectic alloy, and select according to the alloy composition Raw materials, each raw material is mixed according to the ratio, vacuum smelted with nitrogen, and borax covering agent is added on the surface of the alloy, the alloy is heated to 400°C for 15-25min, the alloy melt is heated to 950°C, and kept for 20-30min , while adding electromagnetic stirring to make the alloy composition uniform, then cooling down to 400-420 ° C for 20 minutes, and then vacuum casting to prepare the SnBi57 hypoeutectic alloy. The alloy ingot is processed into a cryogenic alloy mold.

Embodiment 2

[0040] A method for modifying a SnBi hypoeutectic alloy using a topological short-range ordered structure. The method induces the transformation of the topological short-range ordered structure through temperature elements. The specific operation steps are: select a SnBi56Cu1.0 hypoeutectic alloy, Select the raw materials for the ingredients, mix the raw materials according to the ratio, vacuum smelt with nitrogen, add boric acid covering agent on the surface of the alloy, heat the alloy to 400°C for 15-25min, heat the alloy melt to 980°C, and keep it warm for 20 ~ 30min, while adding electromagnetic stirring to make the alloy composition uniform, then cooling down to 400-420°C for 30min, and then vacuum casting to prepare a SnBi56Cu1.0 hypoeutectic alloy. The alloy ingots are processed and manufactured into solder sheets for low-temperature brazing of corresponding specifications.

Embodiment 3

[0042] A method for modifying a SnBi hypoeutectic alloy by using a topological short-range ordered structure. The method induces the transformation of the topological short-range ordered structure by temperature elements. The specific operation steps are: select a SnBi45Ag0.3 hypoeutectic alloy, Select the raw materials for the ingredients, mix each raw material according to the ratio, vacuum-fill nitrogen for melting, add boric acid covering agent on the surface of the alloy, heat the alloy to 410°C for 15-25min, raise the temperature of the alloy melt to 1000°C, and keep it warm for 20 ~30min, while adding electromagnetic stirring to make the alloy composition uniform, then cooling down to 400-420°C for 20min, and then vacuum casting to prepare the SnBi45Ag0.3 hypoeutectic alloy. The alloy ingots are smelted and centrifugally atomized to manufacture solder powder for low-temperature brazing of corresponding specifications.

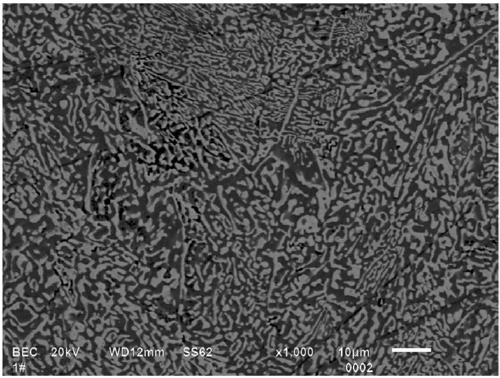

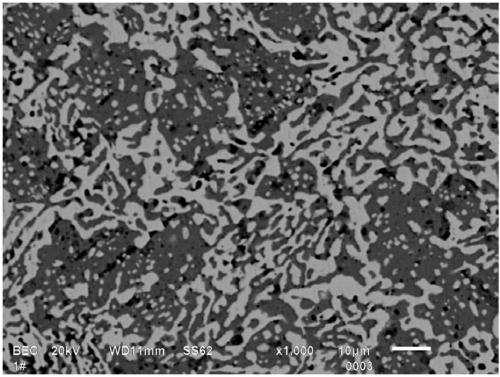

[0043] Such as figure 1 As shown, it is the photo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com