Smelting method for comprehensively recovering rare earth and fluorine from bastnaesite

A technology of bastnaesite and smelting methods, which is applied to the improvement of process efficiency, calcium/strontium/barium fluoride, calcium/strontium/barium halide, etc., which can solve the problem of low value of fluorine resource recovery and utilization, and unrecovered heat Utilization, failure to meet sales requirements and other problems, to achieve the effect of improving utilization rate and economic benefits, increasing hydrochloric acid leaching rate, saving resources and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

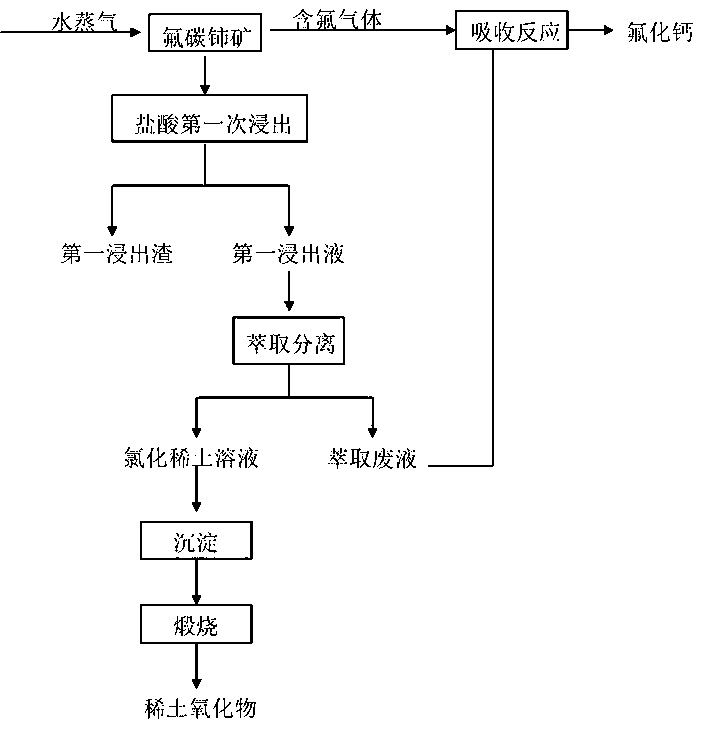

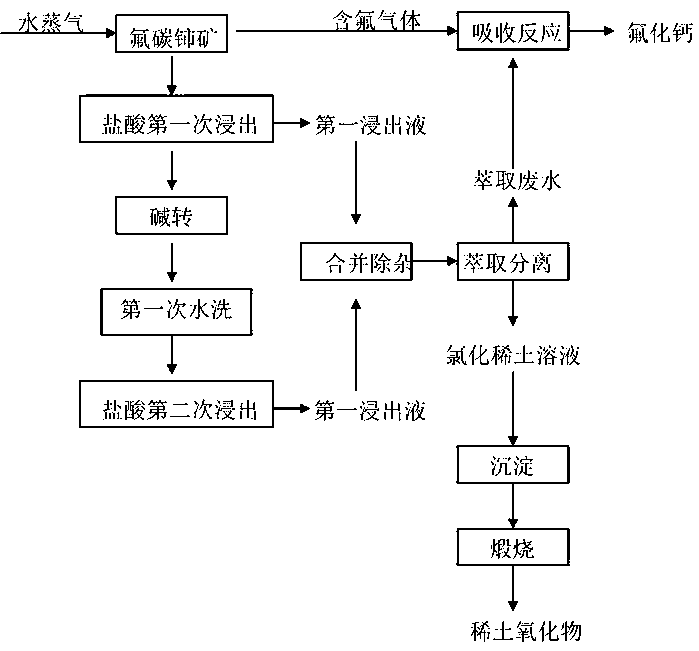

[0035] Such as figure 1 As shown, this embodiment provides a smelting method for comprehensively recovering rare earths and fluorine from bastnaesite. The method has simple steps, improves the hydrochloric acid leaching rate of bastnaesite, and efficiently recycles and utilizes resources. Specific steps are as follows:

[0036] Step 1: Roasting the bastnaesite with water vapor to obtain roasted ore and fluorine-containing gas; dissolving the roasted ore with hydrochloric acid for the first time to obtain the first leaching slag and the first leachate containing rare earth chlorides, the first leachate That is the rare earth solution.

[0037] Step 2: saponify the extractant with a calcium ion agent, saponify the rare earth solution with the saponified extractant, and get rid of the calcium-containing extraction wastewater; then the rare earth solution is back-extracted in hydrochloric acid to obtain a rare earth chloride solution; the calcium-containing extraction wastewater ...

Embodiment 2

[0039] Such as figure 1 As shown, this embodiment provides a smelting method for comprehensively recovering rare earths and fluorine from bastnaesite. The method has simple steps, improves the hydrochloric acid leaching rate of bastnaesite, and efficiently recycles and utilizes resources. Specific steps are as follows:

[0040] Step 1: Roast bastnaesite at 800-900°C, and at the same time 3 The dosage per kg*h is passed into water vapor, and roasted for 3-5 hours to obtain roasted ore and fluorine-containing gas; the roasted ore is dissolved with industrial hydrochloric acid for the first time, and the ratio of solid to liquid of roasted ore and hydrochloric acid is 1:1-1.5 (kg : L), and then obtain the first leaching slag and the first leach solution containing rare earth chloride, the first leach solution is the rare earth solution.

[0041] Step 2: saponify the extractant with a calcium ion agent, saponify the rare earth solution with the saponified extractant, and get rid...

Embodiment 3

[0043] Such as figure 1 As shown, this embodiment provides a smelting method for comprehensively recovering rare earths and fluorine from bastnaesite. The method has simple steps, improves the hydrochloric acid leaching rate of bastnaesite, and efficiently recycles and utilizes resources. Specific steps are as follows:

[0044] Step 1: Roast bastnaesite at 800-900°C, and at the same time 3 The dosage per kg*h is passed into water vapor, and roasted for 3-5 hours to obtain roasted ore and fluorine-containing gas; the roasted ore is dissolved with industrial hydrochloric acid for the first time, and the ratio of solid to liquid of roasted ore and hydrochloric acid is 1:1-1.5 (kg : L), and then obtain the first leaching slag and the first leach solution containing rare earth chloride, the first leach solution is the rare earth solution.

[0045] Step 2: According to the volume ratio of 1:0.8-1.5, P507 and sulfonated kerosene are mixed to prepare the extractant, and CaCO 3 The ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com