Iron-based magnetic foam wave-absorbing material with low frequency broadband wave-absorbing performance and preparation method thereof

A technology of magnetic foam and wave-absorbing materials, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve the problems of increasing the difficulty of iron-based magnetic three-dimensional structure materials, reduce the possibility of gravity deposition, increase the loss mechanism, The effect of reducing the amount of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

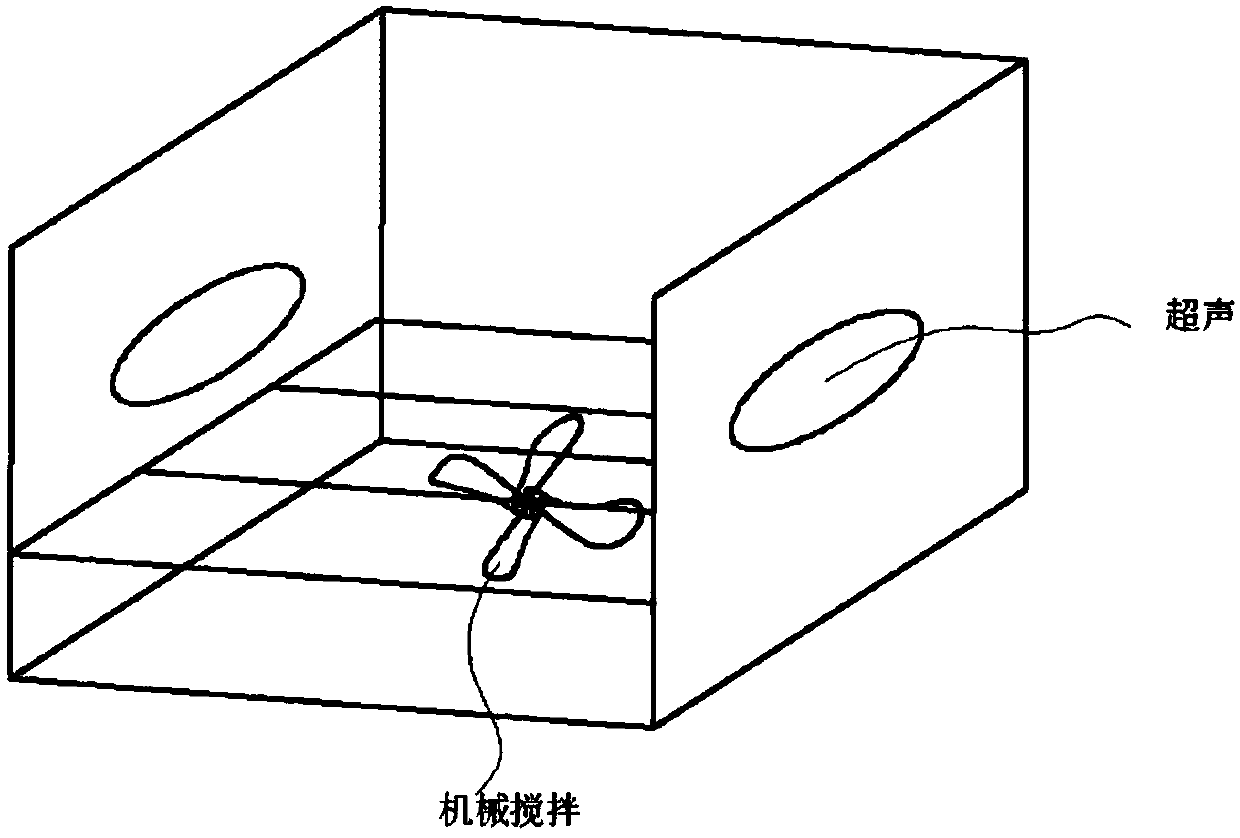

[0034] The preparation process of the iron-based magnetic foam of the present invention is characterized by the introduction of an appropriate amount of suspending agent in the raw material formula, which can effectively increase the suspension time of the flake iron-based magnetic powder in the slurry; And strong mechanical stirring technology, this technology effectively makes the flaky iron-based magnetic powder not settle in the solution for a long time, and disperses evenly.

[0035] The present invention provides a preparation method for the above-mentioned iron-based magnetic foam wave-absorbing material, and the specific process flow is as follows:

[0036] (1) Preparation of slurry

[0037] Mix iron-based magnetic powder, resin, curing agent, suspending agent and solvent in a certain proportion, after ball milling, add solvent, the solute in the slurry accounts for 10% to 50% of the total, and pour it into an ultrasonic stirrer ( image 3 ), suspending the iron powde...

Embodiment 1

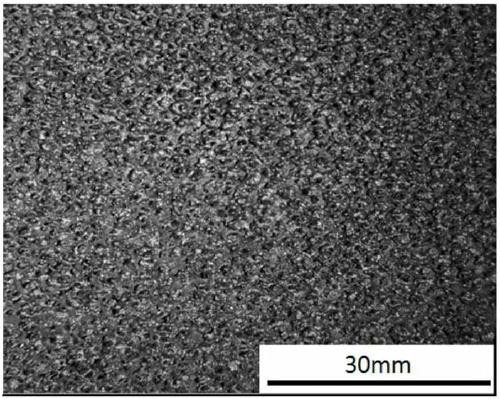

[0045]Mix 150-180 μm flake sendust powder, bismaleimide resin, diaminodiphenylmethane and fumed silica at a weight ratio of 50%: 40%: 8%: 2%, and add dimethyl Acetamide (solute content is 10%), ball milled for 0.5 hours, filtered through a 40-mesh screen, stirred by an ultrasonic mixer for 10 minutes, and then made into a slurry. The polyurethane foam with a pore size of 0.1mm was cut into 100×100×30mm pieces and then immersed in the In the slurry, take out and squeeze out the excess slurry, put it into a centrifuge for centrifugation, and the centrifugal speed is 1500 rpm. After taking it out, blow the hole wall with a high-pressure airflow, put it into an oven for curing after air drying, and the curing temperature gradient is 1 Heat at 100°C for 10 minutes, raise to 150°C for 10 minutes, and raise to 300°C for 1 hour. The above process is repeated several times until the predetermined volume fraction of 20% is reached. Then, the sample is put into a high-temperature and hig...

Embodiment 2

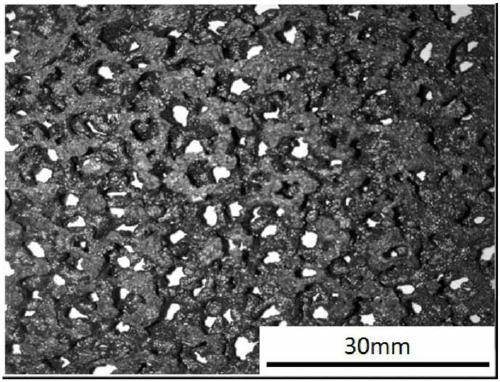

[0048] Mix 0.5-1 μm flake carbonyl iron powder, epoxy resin, polyamide and precipitated silica with a weight ratio of 70%: 20%: 5%: 5%, add absolute ethanol (solute content is 10%), Ball mill for 1 hour, filter with 80-mesh sieve, and make a slurry after being stirred by an ultrasonic mixer. Cut the polyethylene foam with a pore size of 5mm into pieces and immerse in the slurry. Take out and squeeze out the excess slurry, and put it in the centrifuge. Centrifuge in the machine with a centrifugal speed of 200 rpm. After taking it out, blow the hole wall with high-pressure airflow. After air-drying, put it in an oven for curing. The curing program is to heat at 60°C for 10 minutes. The above process is repeated many times until the predetermined volume fraction of 30% is reached. Then, put the sample into a high-temperature and high-pressure reaction vessel with a pressure of 5 MPa, raise the temperature to 150° C., keep the temperature for 2 hours, and remove the prefabricated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com