A kind of preparation method of nickel silicon carbon nitrogen precursor ceramics

A carbon-nitrogen precursor and ceramic technology, which is applied in the field of preparation of nickel-containing silicon carbon-nitrogen wave-absorbing ceramics, can solve the problems of complex preparation process and poor material wave-absorbing performance, and achieves uniform structure, short preparation period and high temperature performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing SiCN (Ni) precursor ceramics by a precursor conversion method, comprising steps as follows:

[0041] (1) Mixing: under a nitrogen atmosphere, weigh 4.61g of polysilazane and 0.39g of nano-nickel powder, mix and stir for 20min to obtain a homogeneous mixture;

[0042] The polysilazane: nickel element mass ratio is 92.2wt%: 7.8wt%;

[0043] (2) Pyrolysis / sintering: put the mixture obtained in step (1) into a tube furnace, and under the protection of nitrogen atmosphere, pyrolyze it at a temperature of 1000 °C for 2 hours, and the heating rate is 3 °C / min, to obtain SiCN (Ni ) precursor ceramics.

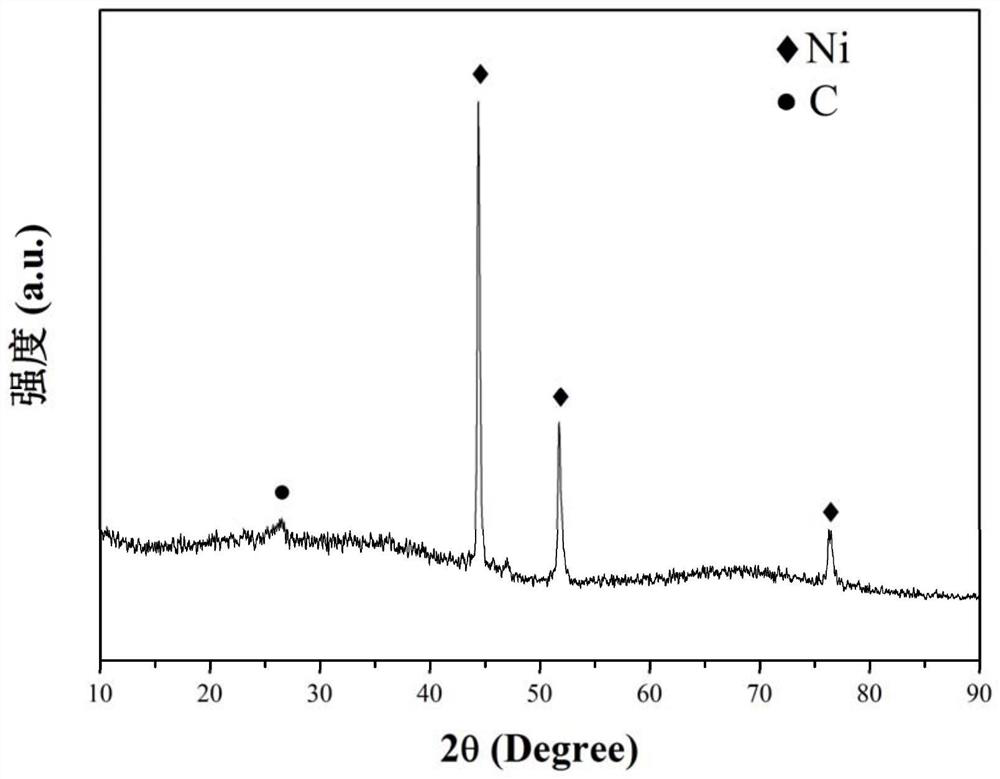

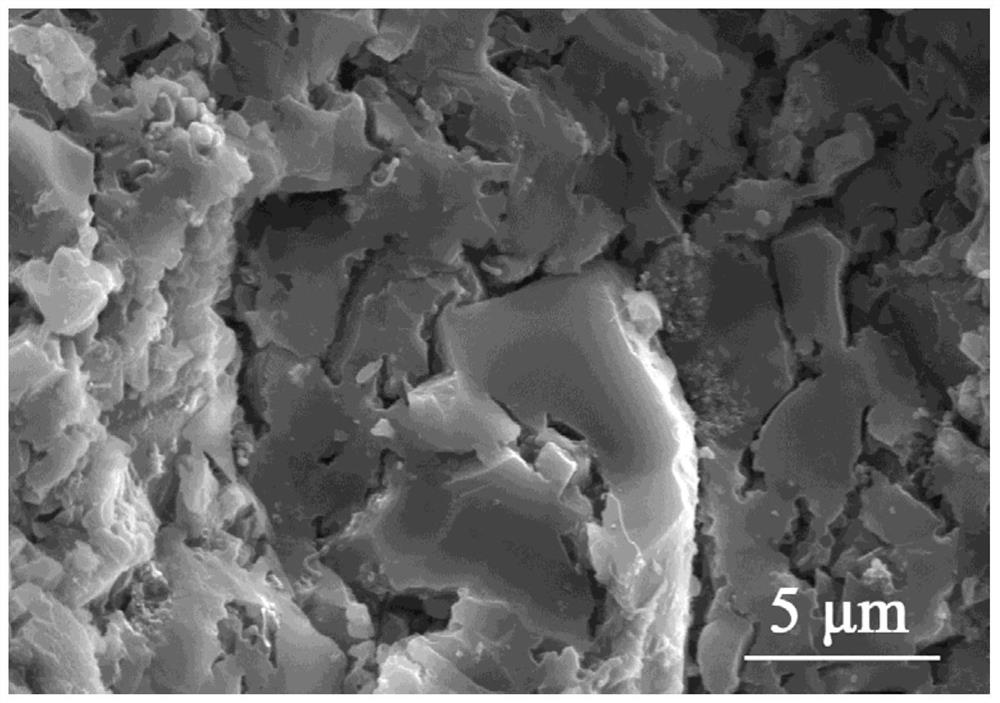

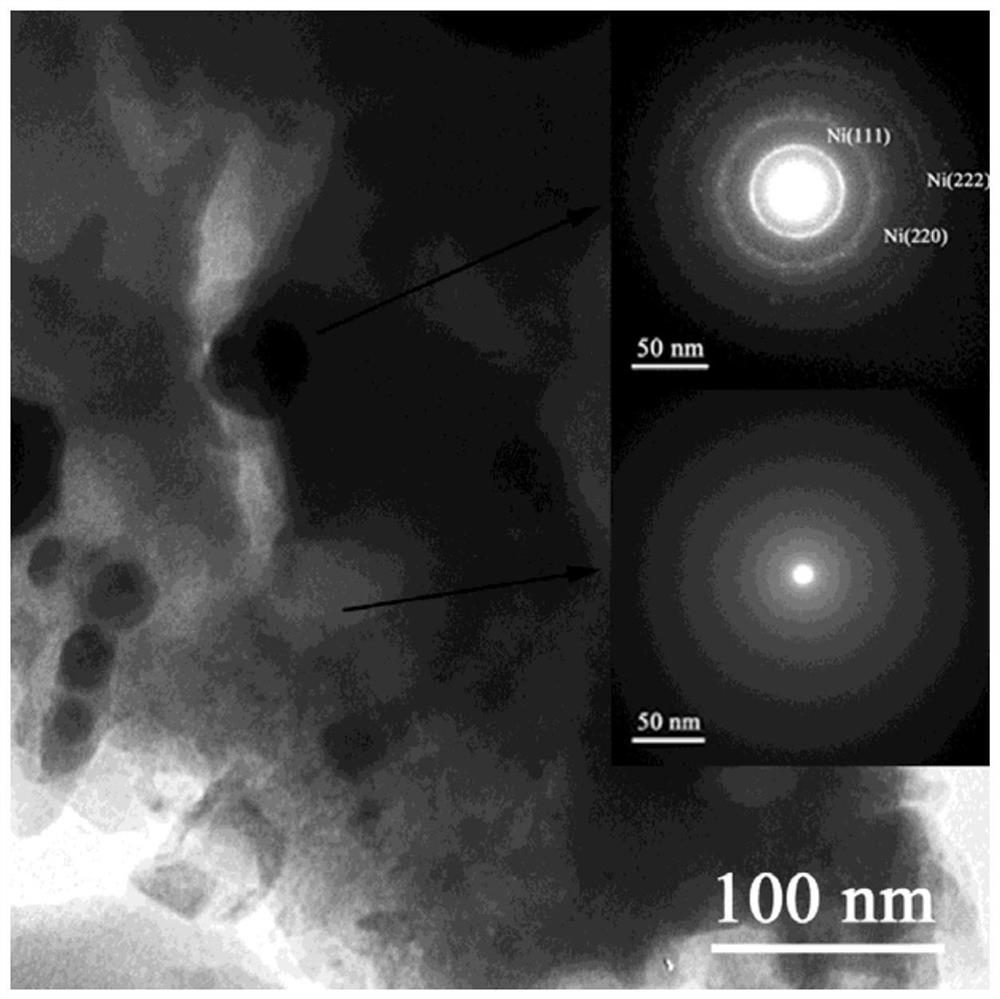

[0044] The SiCN (Ni) precursor ceramic test X-ray diffraction spectrum, SEM photo, TEM figure, hysteresis loop figure and frequency-reflection loss change curve spectrum of the SiCN (Ni) precursor ceramics prepared in this embodiment, such as figure 1 , 2 , 3, 4, and 5.

[0045] Depend on figure 1 It can be seen that the obtained product mainly contai...

Embodiment 2

[0051] A method for preparing SiCN (Ni) precursor ceramics by a precursor conversion method, comprising steps as follows:

[0052] (1) Mixing: under a nitrogen atmosphere, weigh 4.51g of polysilazane and 0.49g of nano-nickel oxide, mix and stir for 20min to obtain a homogeneous mixture;

[0053] The polysilazane: nickel element mass ratio is 92.2wt%: 7.8wt%;

[0054] (2) Pyrolysis / sintering: put the mixture obtained in step (1) into a tube furnace, and under the protection of nitrogen atmosphere, pyrolyze it at a temperature of 1000 °C for 2 hours, and the heating rate is 3 °C / min, to obtain SiCN (Ni ) precursor ceramics.

Embodiment 3

[0061] A method for preparing SiCN (Ni) precursor ceramics by a precursor conversion method, comprising steps as follows:

[0062] (1) Mixing: under a nitrogen atmosphere, weigh 4.5g of polysilazane and 0.5g of nano-nickel powder, mix and stir for 20min to obtain a homogeneous mixture;

[0063] The polysilazane: nickel element mass ratio is 90wt%: 10wt%;

[0064] (2) Pyrolysis / sintering: put the mixture obtained in step (1) into a tube furnace, and under the protection of nitrogen atmosphere, pyrolyze it at a temperature of 1000 °C for 2 hours, and the heating rate is 3 °C / min, to obtain SiCN (Ni ) precursor ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com